Low-temperature air cooling screw heat pump system

An air-cooled screw and heat pump system technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems affecting the smoothness of the compressor, start-up under load, etc., to prevent the phenomenon of start-up under load, reduce influence, condensation low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

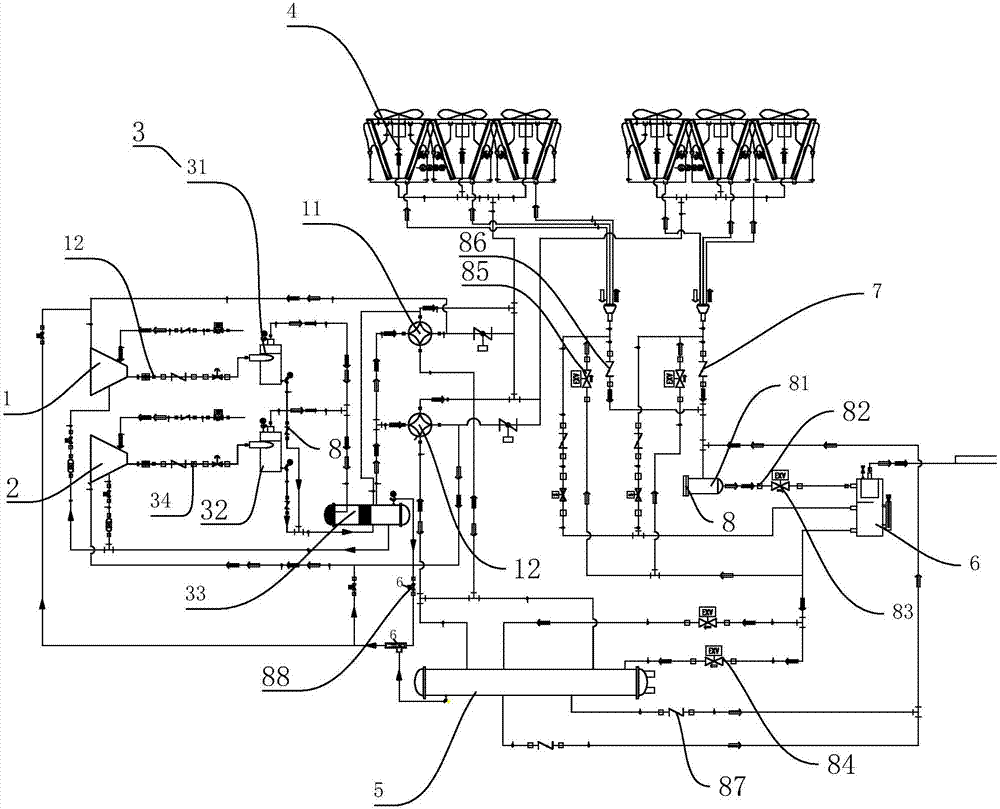

[0063] Embodiment 1, a low-temperature air-cooled screw heat pump system, the main components of the cycle include: two screw compressors, three oil separators, two four-way reversing valves, one flash economizer 6, one Typhoon cold fin tube heat exchanger, one shell and tube heat exchanger 5, two cooling expansion valves 84, two heating expansion valves 85 and one main liquid supply electronic expansion valve 83. Such as figure 1 As shown, the first screw compressor 1 and the second screw compressor 2 are arranged in parallel, and the first screw compressor 1 and the second screw compressor 2 are equipped with a muffler 12 to reduce the noise during operation. The air inlets of the two compressors are provided with one-way exhaust valves communicating with them to control the flow of air.

[0064] Such as figure 1 As shown, an oil separation unit 3 is provided outside the two screw compressors, and the oil separation unit 3 includes a secondary oil separator 33 . The first...

Embodiment 2

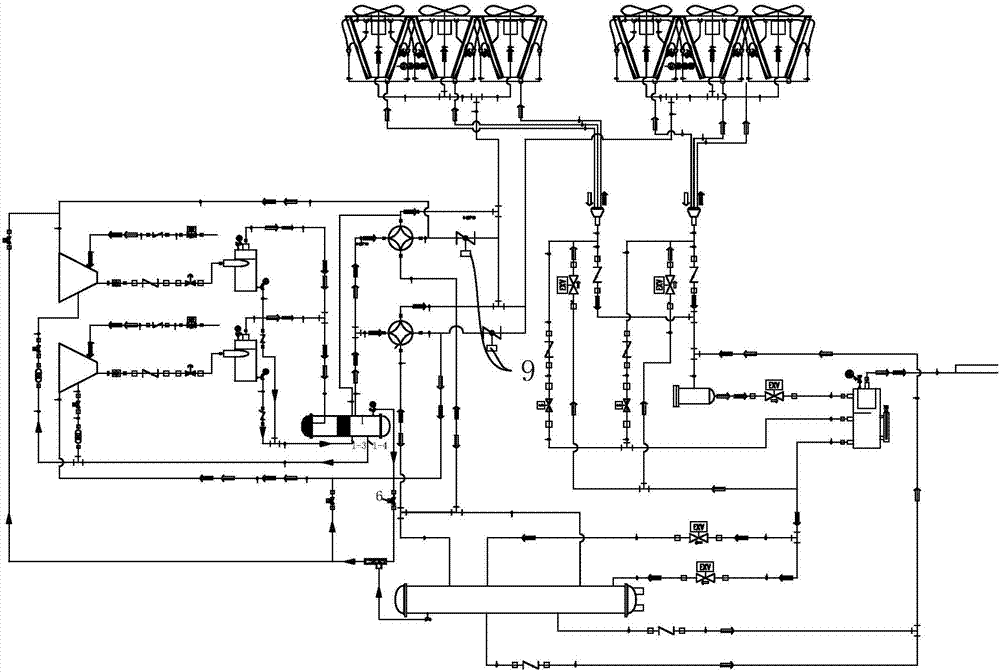

[0073] Embodiment 2, a kind of low-temperature air-cooled screw heat pump system, such as figure 2 As shown, the first four-way reversing valve 11 is connected to the air return port of the air-cooled finned tube heat exchanger, and the suction butterfly valve 9 is installed on the pipeline, while the second four-way reversing valve 21 is connected to another set of air-cooled finned tubes. The air return port of the tube heat exchanger assembly is connected, and a suction butterfly valve 9 is also installed on the pipeline.

Embodiment 3

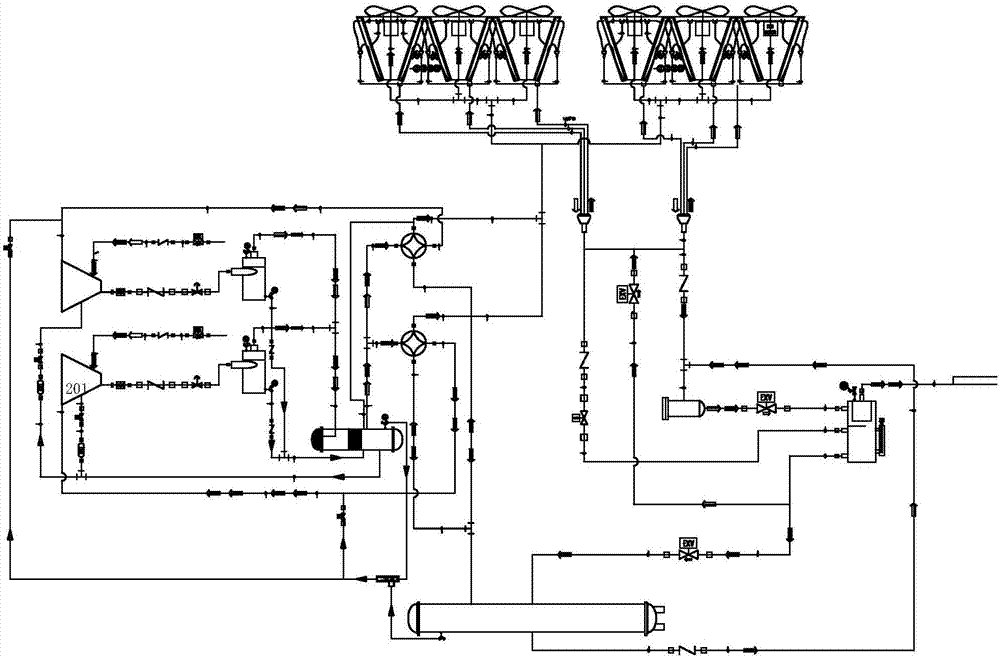

[0074] Embodiment 3, a kind of low-temperature air-cooled screw heat pump system, such as image 3 As shown, the difference from Embodiment 1 or 2 is that the refrigeration expansion valve 84 and the heating expansion valve 85 are shared, and the refrigeration one-way valve 86 and the heating one-way valve 87 are two-way design, that is, the front of the valve is connected in parallel, After the valve is connected in parallel. According to design requirements, a large-capacity refrigeration system can use two-way parallel small valves or a single large valve, and a small-capacity system can use a single small valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com