Modified oxidative single-walled carbon nanohorn, preparation method and application thereof, and method for adsorbing antibiotics

A single-walled carbon nanohorn and carbon nanohorn technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc. The degree is not good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

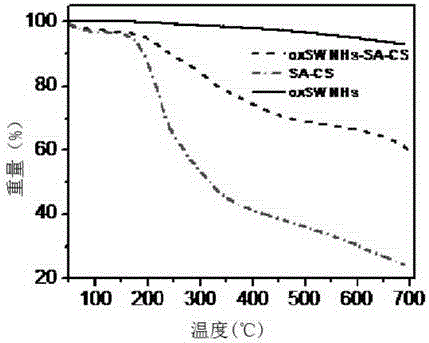

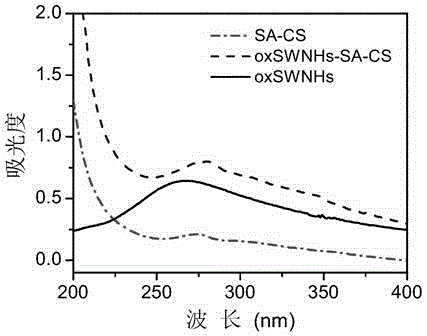

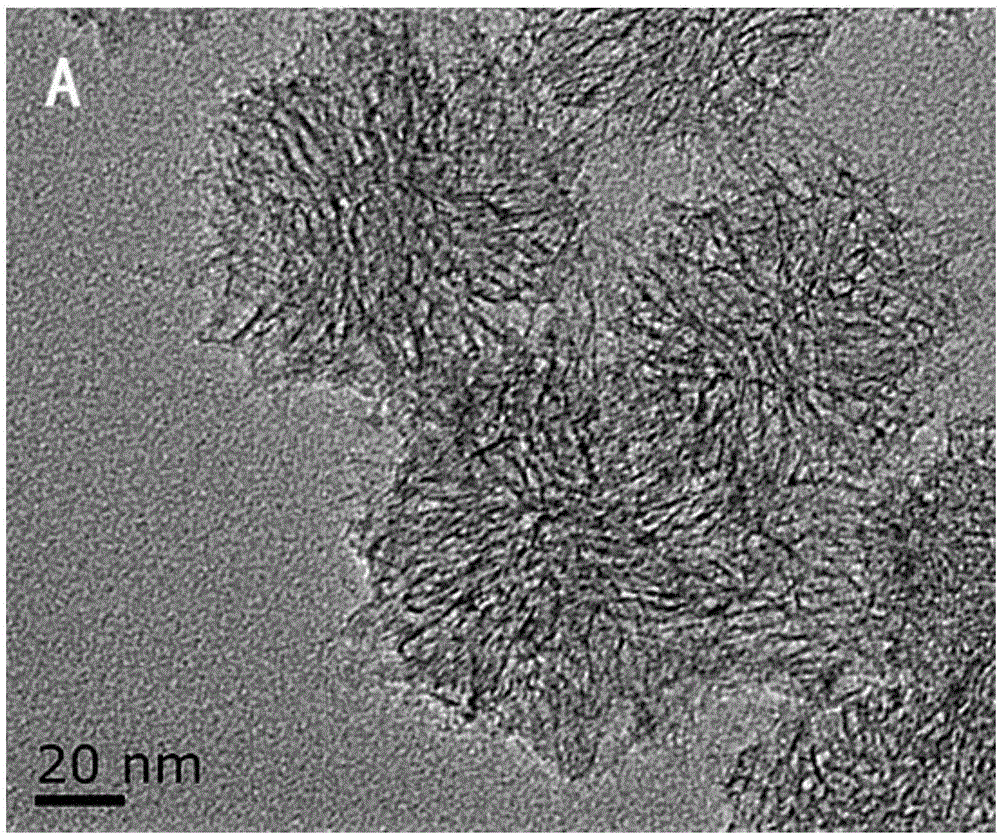

[0055] Preparation of modified oxidized single-walled carbon nanohorns:

[0056] (1) 0.531g of stearic acid was ultrasonically dissolved in 13.27g of ethanol, and then 1.061g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide, 0.531g of N-hydroxysuccinyl imine, avoid light and stir, and carry out activation reaction for 1.0h to obtain activated stearic acid;

[0057] (2) Dissolve 0.664g of chitosan oligosaccharide in 1.062g of water, add activated stearic acid, react in a reflux reaction at 80°C for 5h, add ethanol after the reaction, and centrifuge to remove impurities to obtain a modifier;

[0058] (3) Ultrasonic mixing of oxidized single-walled carbon nanohorns and water, the ultrasonic frequency is 50kHZ, the temperature is 32°C, mixed for 1 hour, and then the modifier is added, wherein the mass ratio of oxidized single-walled carbon nanohorns, modifiers and water The ratio is 1:18:4000, then ultrasonic at 32°C, 50kHZ for 1.0h, and then centrifuged at 11000rpm / min for 15min...

Embodiment 2

[0060] Preparation of modified oxidized single-walled carbon nanohorns:

[0061] (1) 0.664g stearic acid is ultrasonically dissolved in 13.27g ethanol, then add 1.327g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide, 0.664g N-hydroxysuccinyl imine, avoid light and stir, and carry out activation reaction for 1.2h to obtain activated stearic acid;

[0062] (2) Dissolve 0.796g of chitosan oligosaccharide in 1.194g of water, add activated stearic acid, react in a reflux reaction at 78°C for 6h, add ethanol after the reaction, and centrifuge to remove impurities to obtain a modifier;

[0063] (3) Ultrasonic mixing of oxidized single-walled carbon nanohorns and water, the ultrasonic frequency is 60kHZ, the temperature is 40°C, mixed for 1.5h, and then the modifier is added, wherein the mass of oxidized single-walled carbon nanohorns, modifiers and water The ratio is 1:22:4200, then ultrasonic at 40°C, 60kHZ for 1.5h, and then centrifuged at 15000rpm / min for 20min to remove the supern...

Embodiment 3

[0065] Preparation of modified oxidized single-walled carbon nanohorns:

[0066] (1) 0.398g of stearic acid was ultrasonically dissolved in 13.27g of ethanol, and then 0.796g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide, 0.398g of N-hydroxysuccinyl imine, avoid light and stir, and carry out activation reaction for 0.8h to obtain activated stearic acid;

[0067] (2) Dissolve 0.531g of chitosan oligosaccharide in 0.929g of water, add activated stearic acid, react in a reflux reaction at 82°C for 4 hours, add ethanol after the reaction, and centrifuge to remove impurities to obtain a modifier;

[0068] (3) Ultrasonic mixing of oxidized single-walled carbon nanohorns and water, the ultrasonic frequency is 40kHZ, the temperature is 25°C, mixed for 0.5h, and then the modifier is added, wherein the mass of oxidized single-walled carbon nanohorns, modifiers and water The ratio is 1:1:3800, then ultrasonic at 25°C, 40kHZ for 0.5h, and then centrifuged at 8000rpm / min for 10min to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com