Pulse discharge dressing parameter and motion parameter control method for grinding wheel micro-abrasive dressing

A technology of pulse discharge and motion parameters, which is applied to the parts of grinding machine tools, manufacturing tools, grinding/polishing equipment, etc. It can solve the problems that affect the abrasive grains coming out of the edge, fall off, and the thickness of the electroplating layer is less than 1mm, etc., to simplify the structure of the fixture , easy operation, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0062] A pulse discharge dressing parameter and motion parameter control method for grinding wheel micro-abrasive smoothing, comprising the following steps:

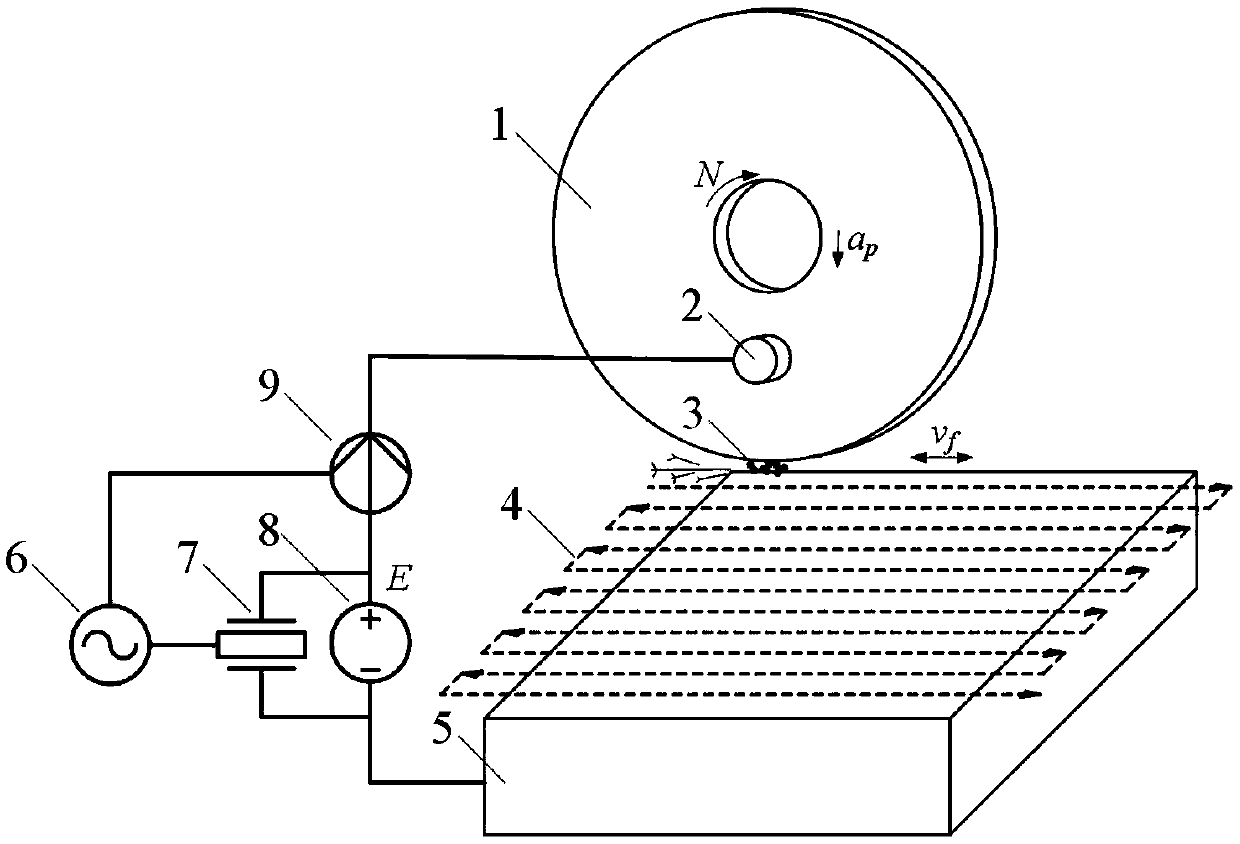

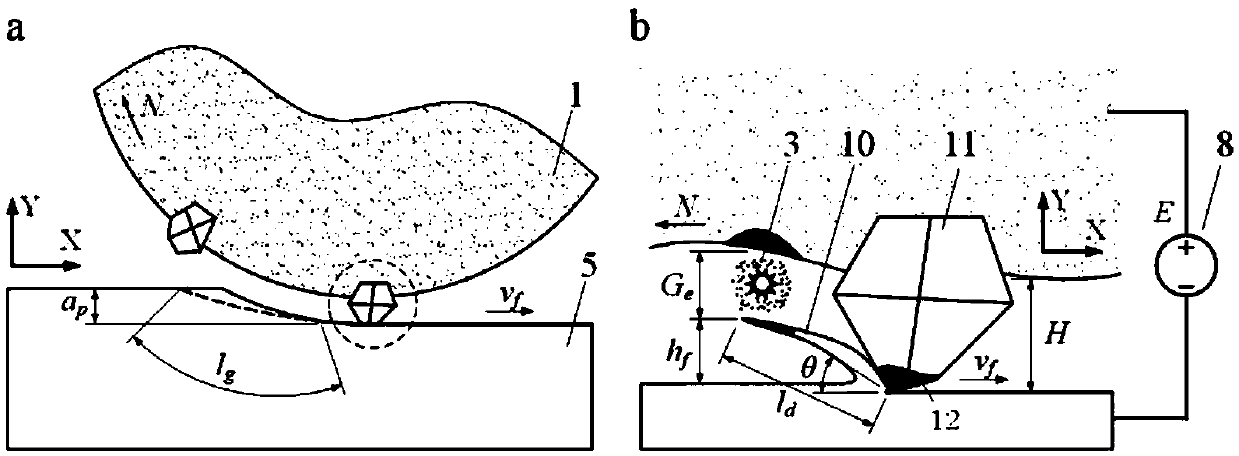

[0063] 1) Fix the diamond grinding wheel 1 and the electrode 5 on the grinding wheel shaft and the workbench of the machine tool respectively, and use wires to connect the diamond grinding wheel 1, the graphite brush 2, the current sensor 9, the power supply 8, and the electrode 5 sequentially in a positive polarity manner to form a Discharge circuit, voltage sensor 7 is connected in parallel with power supply 8 and connects oscilloscope 6 with current sensor 9 (referring to figure 1 );

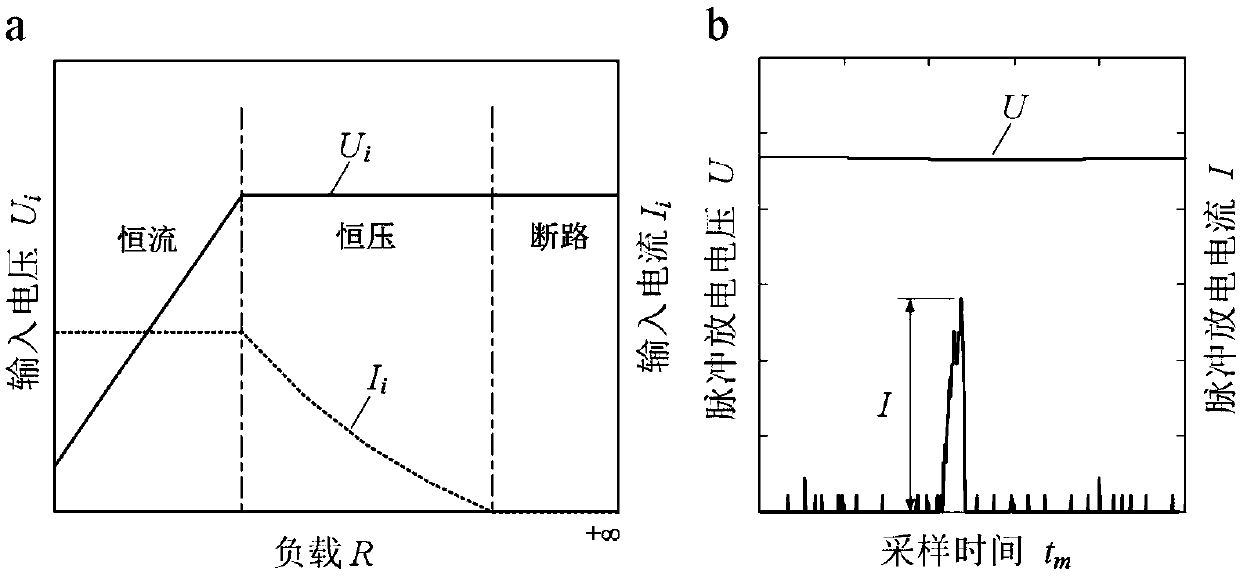

[0064] 2) Carry out the trial grinding operation, load the open circuit voltage E for the discharge circuit, let the diamond gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com