Amphibian vehicle pressure-reducing bottom plate

A technology of bottom plates and steel pipes, applied to amphibious vehicles, hulls, hull parts, etc., can solve problems such as high pressure and hull subsidence, and achieve the effects of light weight, avoiding corrosion, and strong hull weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

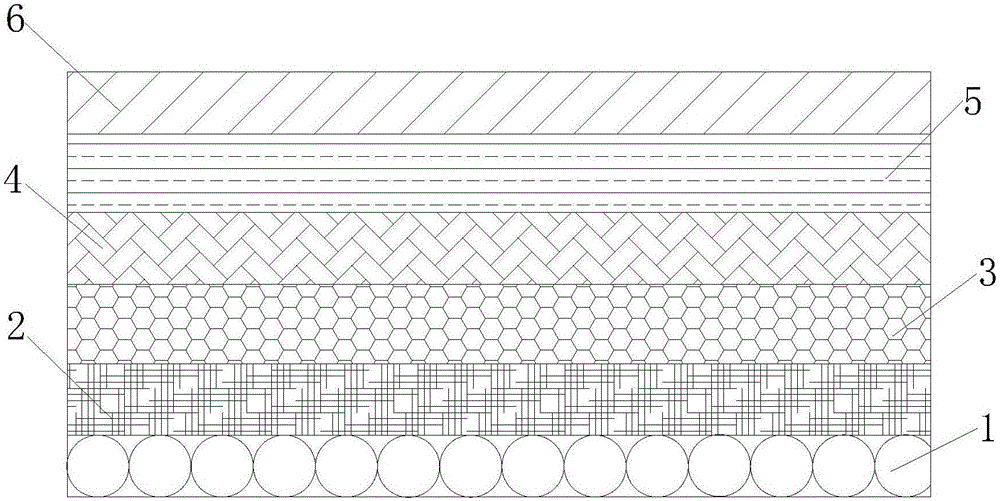

[0020] refer to figure 1 , a kind of amphibious ship decompression bottom plate, steel pipe layer 1, the upper end of steel pipe layer 1 is provided with PVC layer 2, the upper end of PVC layer 2 is provided with galvanized layer 3, the upper end of galvanized layer 3 is provided with anti-compression foam layer 4, anti-compression foam The upper end of the layer 4 is provided with a stainless steel layer 5 , and the upper end of the stainless steel layer 5 is provided with a paint layer 6 .

[0021] The thickness of the stainless steel layer 6 is 2mm, and the stainless steel layer 5 includes the following components by weight percentage: Fe 45%; Cr 17.0%; Ni 8.0%; C 0.07%; Si 0.5%.

[0022] The thickness of the paint layer 6 is 0.05mm, and the paint layer 6 is epoxy anticorrosion paint.

[0023] The steel pipe layer 1 is made of steel pipes with an outer diameter of 45mm arranged and welded sequentially; the steel pipes used in the steel pipe layer 1 may be in a circular sha...

Embodiment 2

[0027] refer to figure 1 , a decompression bottom plate of an amphibious ship, the distribution of its layered structure is the same as in Example 1.

[0028] The thickness of the stainless steel layer 6 is 3mm, and the stainless steel layer 5 includes the following components by weight percentage: Fe 48%; Cr 18.0%; Ni 9.0%; C 0.10%; Si 0.6%.

[0029] The thickness of the paint layer 6 is 0.08mm, and the paint layer 6 is a high chlorinated polyethylene anticorrosion paint.

[0030] The steel pipe layer 1 is made of steel pipes with an outer diameter of 45mm arranged and welded sequentially; the steel pipes used in the steel pipe layer 1 may be in a circular shape.

[0031] The thickness of the anti-compression foam layer 4 is 1.5 mm, and the anti-compression foam layer 4 is polystyrene foam.

[0032] The thickness of the PVC layer 2 is 0.6mm, and the PVC layer 2 includes the following components by weight: 37 parts of polyvinyl chloride, 22 parts of plasticizer, 11 parts of ...

Embodiment 3

[0034] refer to figure 1 , a decompression bottom plate of an amphibious ship, the distribution of its layered structure is the same as in Example 1.

[0035] The thickness of the stainless steel layer 6 is 4mm, and the stainless steel layer 5 includes the following components by weight percentage: Fe 50%; Cr 18.0%; Ni 9.0%; C 0.13%; Si 0.7%.

[0036] The thickness of the paint layer 6 is 0.11 mm, and the paint layer 6 is an acrylic anticorrosion paint.

[0037] The steel pipe layer 1 is made of steel pipes with an outer diameter of 45mm arranged and welded sequentially; the steel pipes used in the steel pipe layer 1 may be in a circular shape.

[0038] The thickness of the anti-compression foam layer 4 is 2 mm, and the anti-compression foam layer 4 is polypropylene foam and polyethylene foam, and the mixing ratio is 2:1.

[0039] The thickness of the PVC layer 2 is 0.8mm, and the PVC layer 2 includes the following components by weight: 41 parts of polyvinyl chloride, 26 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com