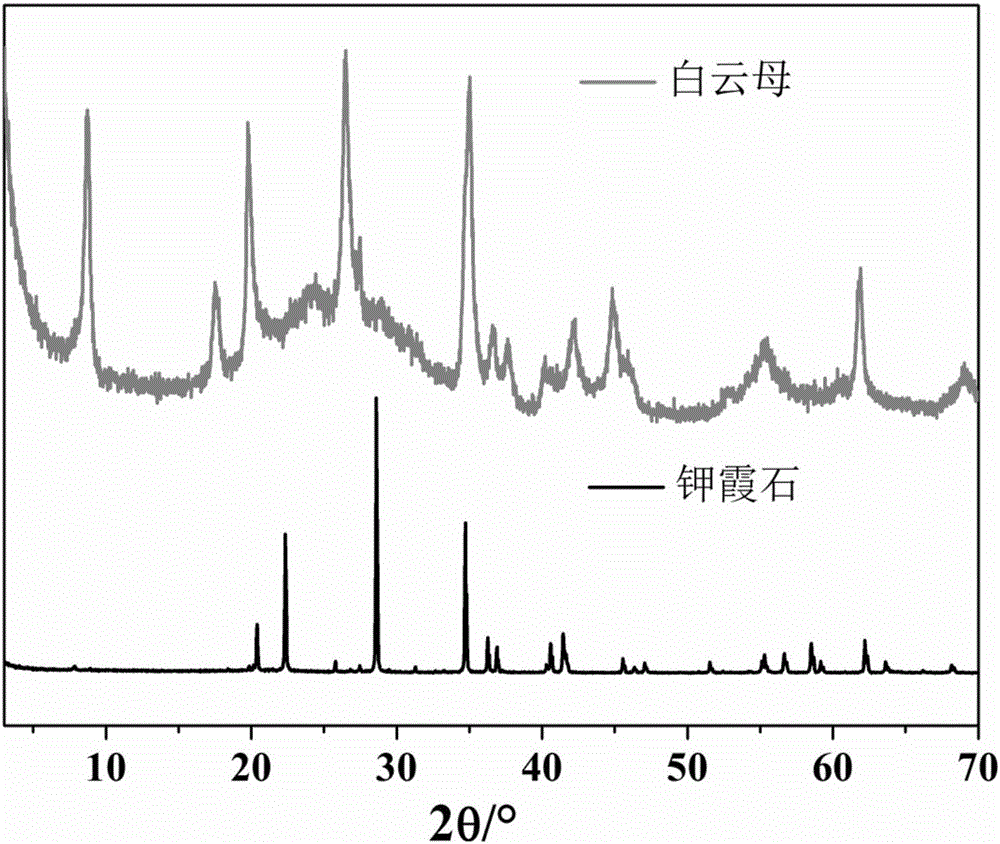

Method for synthesizing nano-white mica byproduct (potassium nitrate) by use of kaliophilite powder

A technology of potassium nepheline powder and muscovite, which is applied in the field of fine chemical material preparation, can solve the problems of high price, complicated production process, shortage of potassium chloride resources, etc., and achieves low cost, high product purity, good economic benefits and application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

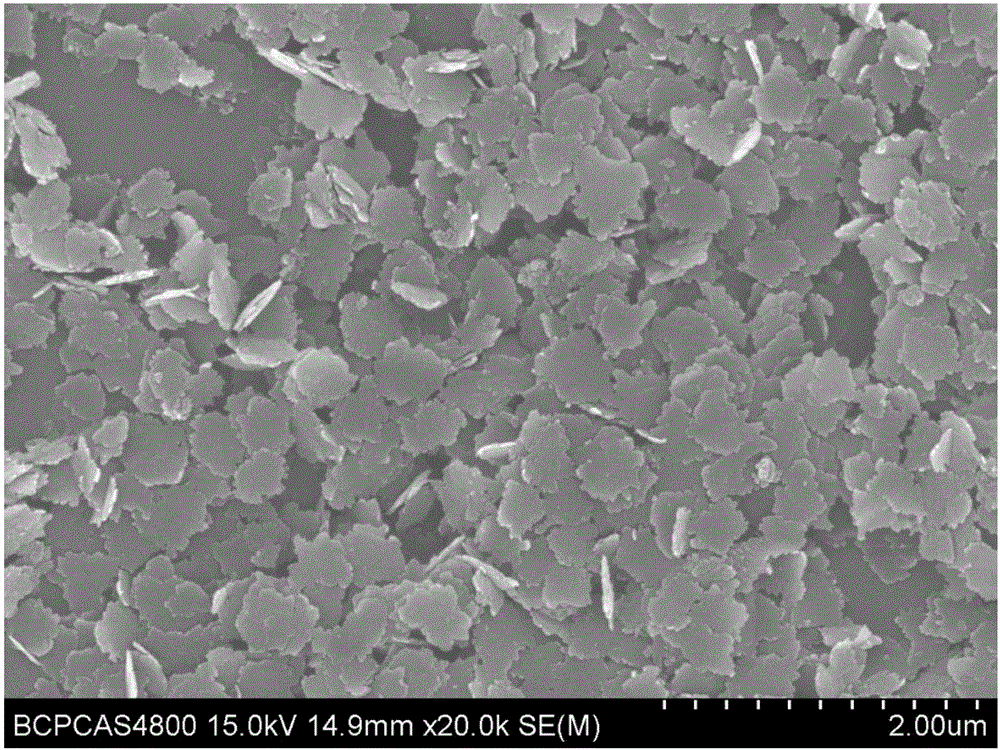

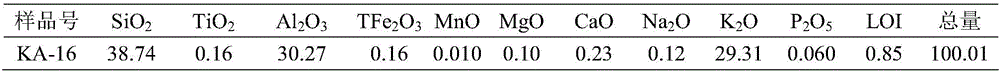

Embodiment 1

[0027] Weigh 100 g of ka-nepheline powder, 37 g of nitric acid with a mass fraction of 67%, 0.3 g of acetic acid, and 500 mL of distilled water. First mix nitric acid, acetic acid and distilled water to form a solution, then pour the kalephine powder into the solution, stir evenly to form a slurry, put it into a stainless steel reaction kettle with a polytetrafluoroethylene liner, and put the water under the condition of 250 ° C After thermal reaction for 18 hours, immediately take out the reaction kettle and put it into cold water for rapid cooling. After the kettle is opened, the solid-liquid separation is carried out, and the filtrate is evaporated and crystallized at 110-120°C to obtain the potassium nitrate product. The dissolution rate of potassium oxide measured by ICP is 68.7%, and K in potassium nitrate 2 The O content is 45.31%, and the purity of potassium nitrate equivalent is greater than 97%. The filter cake is washed with distilled water until the pH of the filt...

Embodiment 2

[0031] Weigh 100 g of ka-nepheline powder, 55 g of nitric acid with a mass fraction of 67%, 1.8 g of acetic acid, and 2000 mL of distilled water. First mix nitric acid, acetic acid and distilled water to form a solution, then pour the kalephine powder into the solution, stir evenly to form a slurry, put it into a stainless steel reaction kettle with a polytetrafluoroethylene liner, and put the water under the condition of 250 ° C After thermal reaction for 24 hours, immediately take out the reaction kettle and put it into cold water for rapid cooling. After the kettle is opened, the solid-liquid separation is carried out, and the filtrate is evaporated and crystallized at 110-120°C to obtain the potassium nitrate product. The dissolution rate of potassium oxide measured by ICP was 70.2%, and K in potassium nitrate 2 The O content is 45.11%, and the purity of potassium nitrate equivalent is greater than 96%. The filter cake is washed with distilled water until the pH of the fi...

Embodiment 3

[0033] Weigh 100 g of ka-nepheline powder, 40 g of nitric acid with a mass fraction of 67%, 1.0 g of acetic acid, and 1000 mL of distilled water. First mix nitric acid, acetic acid and distilled water to form a solution, then pour the kalnite powder into the solution, stir evenly to form a slurry, put it in a stainless steel reaction kettle with a polytetrafluoroethylene liner, and heat it under the condition of 250 ℃ After reacting for 72 hours, take out the reaction kettle immediately and put it into cold water for rapid cooling. After the kettle is opened, the solid-liquid separation is carried out, and the filtrate is evaporated and crystallized at 110-120°C to obtain the potassium nitrate product. The dissolution rate of potassium oxide measured by ICP is 69.7%, and K in potassium nitrate 2 The O content is 45.21%, and the purity of potassium nitrate equivalent is greater than 97%. The filter cake is washed with distilled water until the pH value of the filtrate is 9-10,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com