Preparation method of tributyl phosphate

A technology of tributyl phosphate and n-butanol, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of low product yield recovery, environmental pollution, low reaction temperature and other issues, to achieve the effects of cheap price, safe storage, improved yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

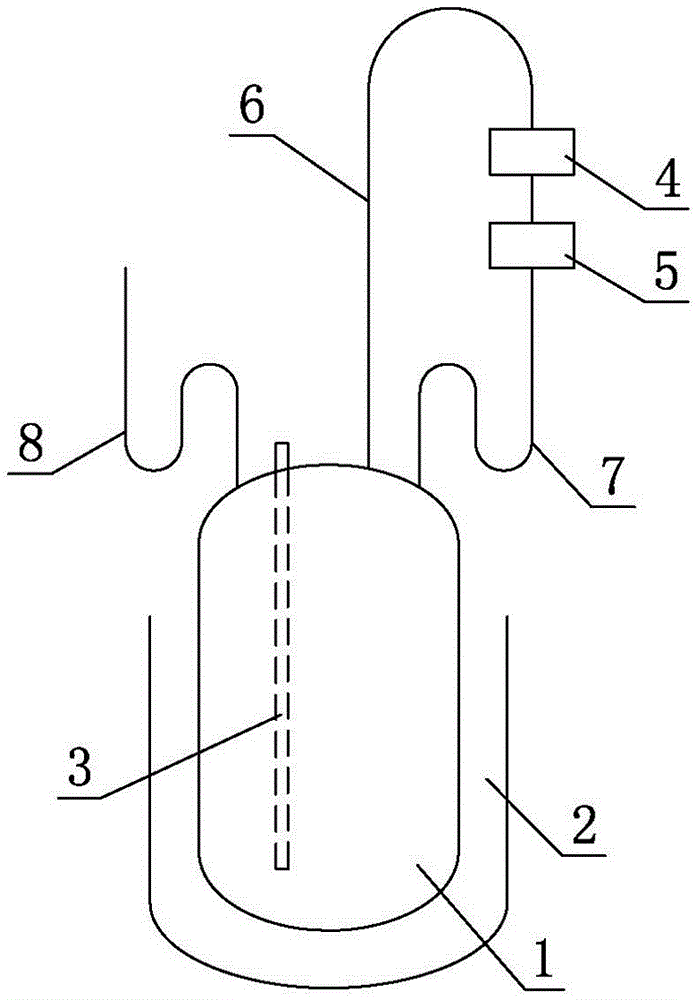

Image

Examples

Embodiment 1

[0020] A kind of preparation method of tributyl phosphate described in the present embodiment, comprises the following steps:

[0021] (1) Add n-butanol, sodium metal and toluene to the reaction device in sequence, then stir and heat up to reflux to generate a mixed solution containing sodium butoxide; wherein, the hydrogen generated by the reaction is removed from the solvent toluene by the separator in the reaction device After separation, the reaction temperature is controlled at 28°C, and the stirring speed is 50r / min, and the reaction time is controlled at 2.3 hours; the molar mass ratio of n-butanol and sodium metal is 1.1: 1, and 100g solvent is added for every 1mol sodium metal;

[0022] (2) Cool the mixed solution containing sodium butoxide to 15°C, add phosphorus oxychloride dropwise to the reaction device within 30 minutes to carry out esterification reaction, and generate a mixed solution containing tributyl phosphate; the esterification reaction temperature Contro...

Embodiment 2

[0027] A kind of preparation method of tributyl phosphate described in the present embodiment, comprises the following steps:

[0028] (1) Add n-butanol, sodium metal and toluene to the reaction device in sequence, then stir and heat up to reflux to generate a mixed solution containing sodium butoxide; wherein, the hydrogen generated by the reaction is removed from the solvent toluene by the separator in the reaction device After separation, the reaction temperature is controlled at 30°C, and the stirring speed is 60r / min, and the reaction time is controlled at 2 hours; the molar mass ratio of n-butanol and sodium metal is 1.4: 0.8, and 97g solvent is added for every 1mol sodium metal;

[0029] (2) Cool the mixed solution containing sodium butoxide to 12°C, add phosphorus oxychloride dropwise to the reaction device within 30 minutes to carry out esterification reaction, and generate a mixed solution containing tributyl phosphate; the esterification reaction temperature Control...

Embodiment 3

[0033] A kind of preparation method of tributyl phosphate described in the present embodiment, comprises the following steps:

[0034] (1) Add n-butanol, sodium metal and toluene to the reaction device in sequence, then stir and heat up to reflux to generate a mixed solution containing sodium butoxide; wherein, the hydrogen generated by the reaction is removed from the solvent toluene by the separator in the reaction device After separation, the reaction temperature is controlled at 32°C, the stirring speed is 55r / min, and the reaction time is controlled at 1.8 hours; the molar mass ratio of n-butanol and sodium metal is 0.8: 1.2, and 103g solvent is added for every 1mol sodium metal;

[0035] (2) Cool the mixed solution containing sodium butoxide to 18°C, add phosphorus oxychloride dropwise to the reaction device within 30 minutes to carry out esterification reaction, and generate a mixed solution containing tributyl phosphate; the esterification reaction temperature Control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com