Novel bubbling foam stabilizer and preparation method thereof

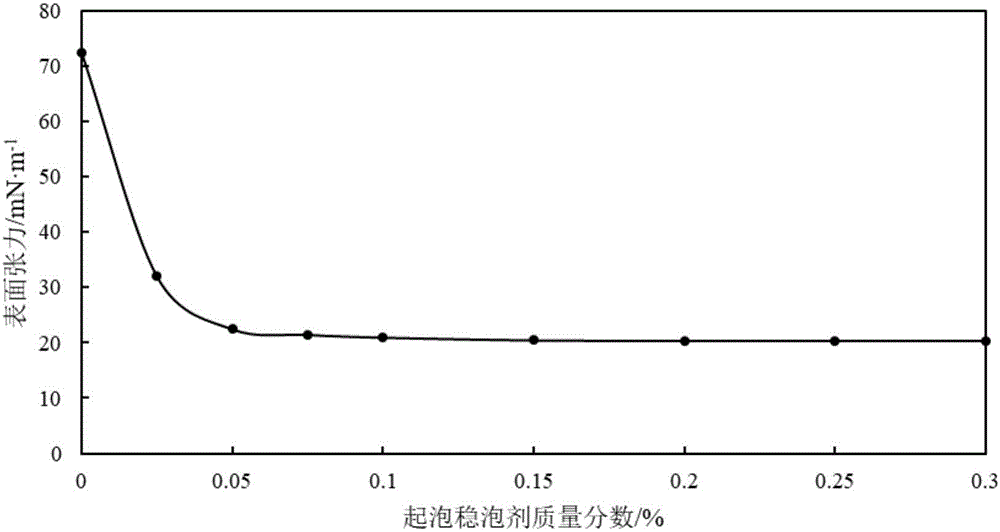

A foam stabilizer and a new technology, applied in the field of new foam stabilizer and its preparation, can solve the problems of foam volume, low half-life, high dosage, unsatisfactory effect, etc., achieve good foam stability, improve lock The effect of liquid capacity and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

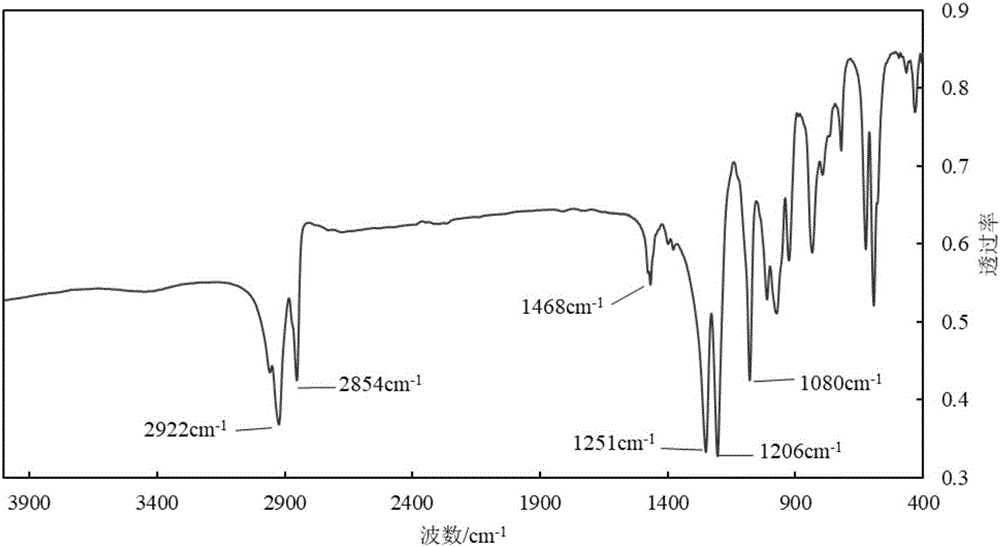

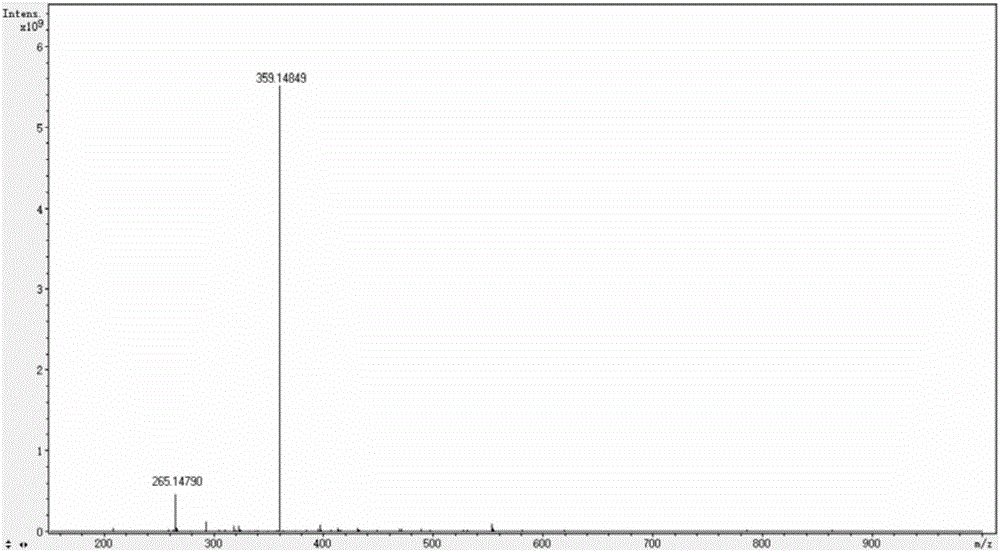

[0039] A novel foaming foam stabilizer of surfactant class, the structure is as shown in formula (I):

[0040]

[0041] The preparation method of surfactant class novel foaming foam stabilizer I described in the present embodiment comprises the following steps:

[0042] (1) Add 1,3-propanediol 85ml, epichlorohydrin 200ml, tetrabutylammonium bisulfate Bu 4 NHSO 4(TBAS) 8g, stirred at 40°C; 600ml of 50% NaOH aqueous solution was added dropwise with a constant pressure dropping funnel, and continued to stir at 60°C for 2.5h. Separate the upper organic phase with a separatory funnel, add ethanol, heat filter to remove inorganic salts, distill off ethanol and epichlorohydrin to obtain epoxy ether with a yield of 96.7% and a purity of 90.8%.

[0043] (2) Add 265ml of tetrapropylene into the three-necked flask, slowly add 65ml of cold concentrated sulfuric acid drop by drop at 0°C with a constant pressure dropping funnel, and after stirring for 2 hours, transfer the mixture to t...

Embodiment 2

[0051] A novel foaming foam stabilizer of surfactant class, the structure is as shown in formula (I):

[0052]

[0053] The preparation method of surfactant class novel foaming foam stabilizer I described in the present embodiment comprises the following steps:

[0054] (1) Add 1,3-propanediol 70ml, epichlorohydrin 150ml, tetrabutylammonium bisulfate Bu 4 NHSO 4 (TBAS) 5g, stirred at 35°C; 500ml of 50% NaOH aqueous solution was added dropwise with a constant pressure dropping funnel, and continued to stir at 55°C for 2h. Separate the upper organic phase with a separatory funnel, add ethanol, heat filter to remove inorganic salts, distill off ethanol and epichlorohydrin to obtain epoxy ether with a yield of 93.0% and a purity of 90.1%.

[0055] (2) Add 200ml of tetrapropylene into the three-necked flask, slowly add 60ml of cold concentrated sulfuric acid drop by drop at a temperature of 0°C with a constant pressure dropping funnel, and after stirring for 2 hours, transfer ...

Embodiment 3

[0059] A novel foaming foam stabilizer of surfactant class, the structure is as shown in formula (I):

[0060]

[0061] The preparation method of surfactant class novel foaming foam stabilizer I described in the present embodiment comprises the following steps:

[0062] (1) Add 1,3-propanediol 100ml, epichlorohydrin 250ml, tetrabutylammonium bisulfate Bu 4 NHSO 4 (TBAS) 15g, stirred at 45°C; 650ml of 50% NaOH aqueous solution was added dropwise with a constant pressure dropping funnel, and continued to stir at 65°C for 3h. Separate the upper organic phase with a separatory funnel, add ethanol, heat filter to remove inorganic salts, distill off ethanol and epichlorohydrin to obtain epoxy ether with a yield of 95.5% and a purity of 94.2%.

[0063] (2) Add 300ml of tetrapropylene into the three-necked flask, and slowly add 70ml of cold concentrated sulfuric acid dropwise at 0°C with a constant pressure dropping funnel. After stirring for 3 hours, transfer the mixture to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com