Preparation method of ice wine

A technology for ice wine and wine, applied in the field of wine processing, can solve the problems of harsh production and production process conditions, low yield of ice grape juice, limited production volume, etc., to avoid food safety risks, strong natural sterilization function, and equipment cost. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

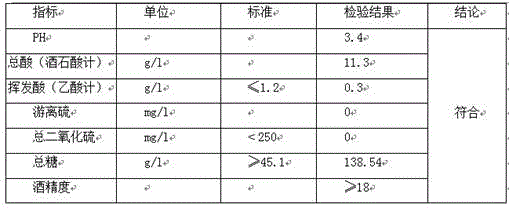

Examples

Embodiment 1

[0040]A method for preparing ice wine, comprising the following specific steps:

[0041] (1) Picking and processing of raw materials: collect mature fruits, remove immature, bird and insect diseases, and rotten fruits, and remove stems and crush them; the sugar content of raw materials is 22 degrees (°Brix).

[0042] Put the crushed pulp into cans, and add wine yeast and pectinase, the dosage is 300 mg / kg of yeast and 40 mg / kg of pectinase; the amount of grapes entering is about 4 / 5 of the volume, and pectin is added first Enzymes, then wine yeast.

[0043] The yeast can be LaIVin QA23 or domestic wine active dry yeast CEC01.

[0044] (2) Fermentation: Monitor the temperature and sugar content (°Brix) of the grape pulp at any time, stir once every 3 hours to lower the temperature, and control the fermentation temperature within 30°C; the sugar content is ≥13°C.

[0045] (3) Terminate fermentation. When the sugar content in the pulp drops to 14 degrees, filter to remove skin ...

Embodiment 2

[0051] A method for preparing ice wine, comprising the steps of crushing grapes, fermenting, freezing, deicing and dehydrating, second fermentation and precipitation filtration, the specific steps are as follows:

[0052] (1) Crush the grapes and put them in cans; the raw material glucose is 21 degrees.

[0053] (2) Fermentation: wine yeast and pectinase are added to the pulp for fermentation; pectinase can clarify and facilitate the separation of wine. Calculated by the weight of grape pulp, the yeast is 200 mg / kg, and the pectinase is 15 mg / kg.

[0054] Monitor the temperature and sugar content (°Brix) of the grape pulp at any time, stir once every 3 hours to reduce the temperature, and the fermentation time can be 2 days.

[0055] (3) Termination of fermentation: When the sugar content of the fruit pulp is 13 degrees, filter to remove skin dregs and cool down. When the filtrate is 0°C, stop fermentation to obtain primary wine; the cooling can be gradual, and the cooling ra...

Embodiment 3

[0062] A kind of preparation method of ice wine, concrete steps are as follows:

[0063] (1) Picking and requirements of grape essence, select high-quality disease-free Cabernet Sauvignon grapes in areas with a relatively dry climate with a sugar content above 23 degrees (°Brix);

[0064] (2) Fruit picking, collecting mature fruits, and removing immature, bird and insect diseases, and overripe fruits;

[0065] (3) Destemming and crushing, the selected fruit is crushed until the skin is broken.

[0066] (4) Put the crushed pulp into cans, and add wine yeast and pectinase, the dosage is 200 mg / kg of yeast and 40 mg / kg of pectinase;

[0067] (5) Cover the fermentation, monitor the temperature and sugar content (°Brix) of the grape pulp at any time, stir once every 3 hours to lower the temperature, and control the temperature within 30°C; the fermentation time can be 2.5 days. Junior wine 14% Brix, 7 ABV 0 .

[0068] (6) Terminate the fermentation. When the sugar content in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com