Method for preparing food grade coagulated potato protein concentrate

A technology of concentrated protein and potatoes, which is applied in dairy products, milk preparations, plant protein processing, etc., and can solve the problems of grit, insolubility, and bad taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

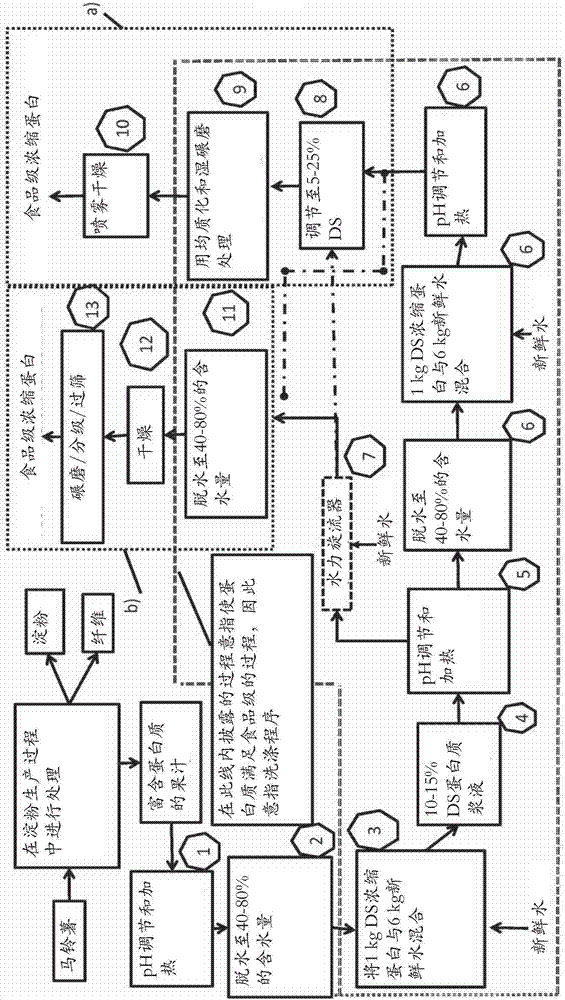

Method used

Image

Examples

example 1

[0060] 10 000 g of potato juice collected from a conventional starch manufacturing process was centrifuged at 3000 x G for 3 min to remove residual starch and fiber particles. Adjust the pH to 3.5. The juice was further heated with steam in a steam autoclave to 130° C. for 3 minutes. The obtained protein slurry was cooled to 40°C. The protein slurry was further centrifuged at 3000 xG for 3 minutes, the supernatant discarded and the resulting pellet mixed with 6 000 g of fresh water. The protein slurry was then mixed for 10 min before centrifugation at 3000 x G for 3 min. The supernatant was again discarded and the pellets were mixed with 6000 g of fresh water during 10 minutes. The protein slurry was centrifuged at 3000 x G for 3 minutes and the supernatant discarded. The pellets were then diluted with fresh water to a content of 10-15% on a dry matter (DM) basis to achieve a viscosity suitable for homogenization in a homogenizer. The slurry was homogenized at 800 bar and...

example 2

[0062] Potato juice from a conventional starch manufacturing process was pumped through a cyclone tank to remove residual fibers and starch granules, then the pH was adjusted to 5.3. The juice was further heated with steam in a steam autoclave to 130° C. for 3 minutes and then dehydrated in a decanter. The protein cake obtained after dehydration was mixed with fresh water to form a slurry with a protein content of 13% on dry matter (DM), and the pH was adjusted to 3.5 with acid. The slurry was heated to 50°C, after which the protein was washed with fresh water through a hydrocyclone. Use equal volumes of protein slurry and fresh water for hydrocyclone washes. The concentrate from the hydrocyclone was diluted with fresh water to a concentration of 3% and dehydrated in a decanter to a content of 40% based on dry matter (DM). The protein cake was further dried in a spin flash dryer to a moisture content of less than 10%. The dry powder is then milled in a conventional classifi...

example 3

[0064] Potato juice from a conventional starch manufacturing process was pumped through a cyclone tank to remove residual fibers and starch granules, then the pH was adjusted to 5.3. The juice was further heated with steam in a steam autoclave to 130° C. for 3 minutes and then dehydrated in a decanter. The protein cake obtained after dehydration was mixed with fresh water to form a slurry with a protein content of 13% on dry matter basis and the pH value was adjusted to 3.5 with acid. The slurry was heated to 50°C, after which the protein concentrate was washed with fresh water through a hydrocyclone. Use equal volumes of protein slurry and fresh water for hydrocyclone washes. The concentrate from the hydrocyclone was diluted with fresh water to a content of 13% on dry matter before performing the second hydrocyclone wash. The concentrate obtained after the second wash was then dewatered on a rotating vacuum drum to a content of 35% on dry matter. The protein cake was furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com