Isomerization catalyst, method for producing straight-chain olefin, and method for producing compound

A technology for straight-chain olefins and a manufacturing method, which can be used in the fields of isomerization to produce hydrocarbons, carbon compound catalysts, catalysts for physical/chemical processes, etc., can solve the problems of insufficient yield, reduced product purity, and difficulty in use, and achieve good efficiency. , the effect of suppressing catalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

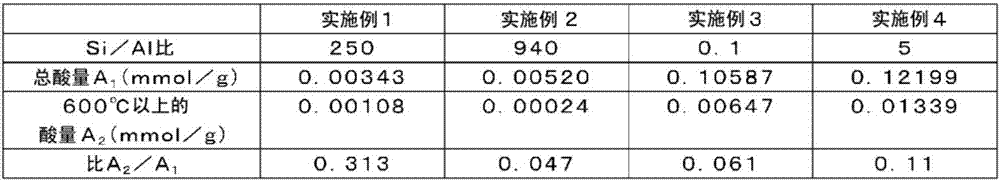

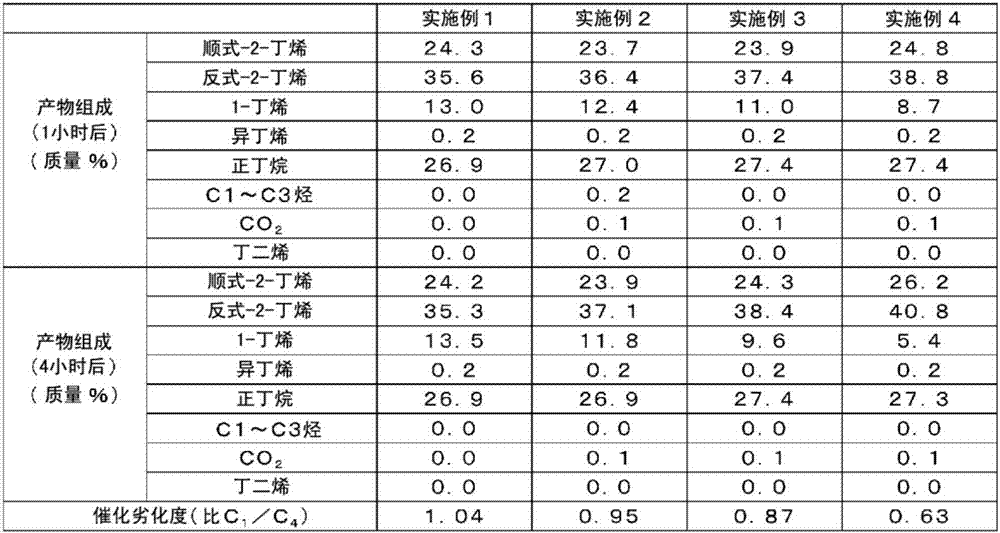

Embodiment 1

[0105] 0.3 cc of an H-β zeolite catalyst (manufactured by Tosoh Corporation, Si / Al=250 (mol / mol)) was filled in a tubular reactor (manufactured by SUS tube). The tube reactor had an inner diameter of 14 mm and a total length of 60 cm. Fill the upper and lower parts of the catalyst with glass beads. The glass beads had an average particle diameter of 1 mm. After connecting this reactor to a circulation reactor, the temperature in the reactor was raised to 350° C. using an electric furnace. A raw material (raw material gas) containing olefin, an oxygen / nitrogen mixed gas (oxygen concentration 10%), and water (steam) were supplied to the heated reactor. The isomerization reaction of olefins is carried out in the above steps.

[0106] In addition, the inflow rates of the raw material gas, air and water (steam) into the reactor were as follows. In addition, the oxygen concentration in the gas supplied to a reactor was 8.5 volume%, and the water concentration was 7.1 volume%. T...

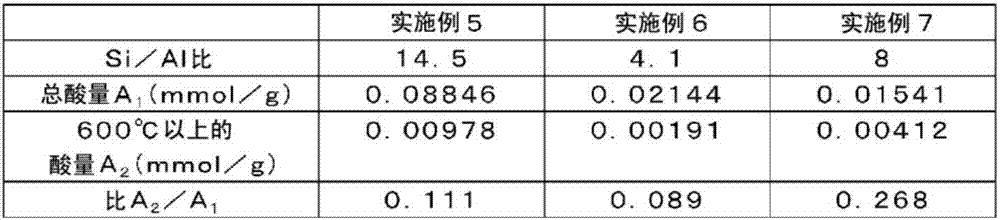

Embodiment 2

[0114] Isomerization of olefins was carried out in the same manner as in Example 1 except that a zeolite catalyst of H-ZSM-5 (manufactured by Tosoh Corporation, Si / Al=940 (mol / mol)) was used as the isomerization catalyst. reaction.

Embodiment 3

[0116] The isomerization reaction of olefins was carried out in the same manner as in Example 1 except that the SAPO-34 zeolite catalyst prepared in reference to Comparative Example 2 of JP-A-2012-91997 was used as the isomerization catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com