Encapsulating resin composition and electronic component device

A technology for a resin composition and electronic components, applied in the fields of electronic component devices and resin compositions for sealing, can solve problems such as insufficient high-temperature storage characteristics, and achieve the effects of excellent high-temperature storage characteristics, sufficient adhesion, and sufficient adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0184] Mix epoxy resin 1 (8.7 parts by mass), phenolic resin curing agent 1 (6.4 parts by mass), inorganic filler 1 (73.72 parts by mass), inorganic filler 2 (10 parts by mass) and compound 1 using a mixer at room temperature. (0.03 parts by mass), coupling agent 1 (0.2 parts by mass), curing accelerator 1 (0.25 parts by mass), colorant (0.4 parts by mass), ion scavenger (0.1 parts by mass) and release agent (0.2 parts by mass ) mixing, followed by roll kneading at 70-100°C. Next, after cooling, it pulverized, and the resin composition for sealing of Example 1 was obtained.

Embodiment 2~8、 comparative example 1~2

[0186] Except having shown the usage-amount (compounding quantity) of each component in Table 1, it carried out similarly to Example 1, and each sealing resin composition of Examples 2-8 and Comparative Examples 1-2 was obtained.

[0187] [Manufacture of semiconductor devices (electronic component devices)]

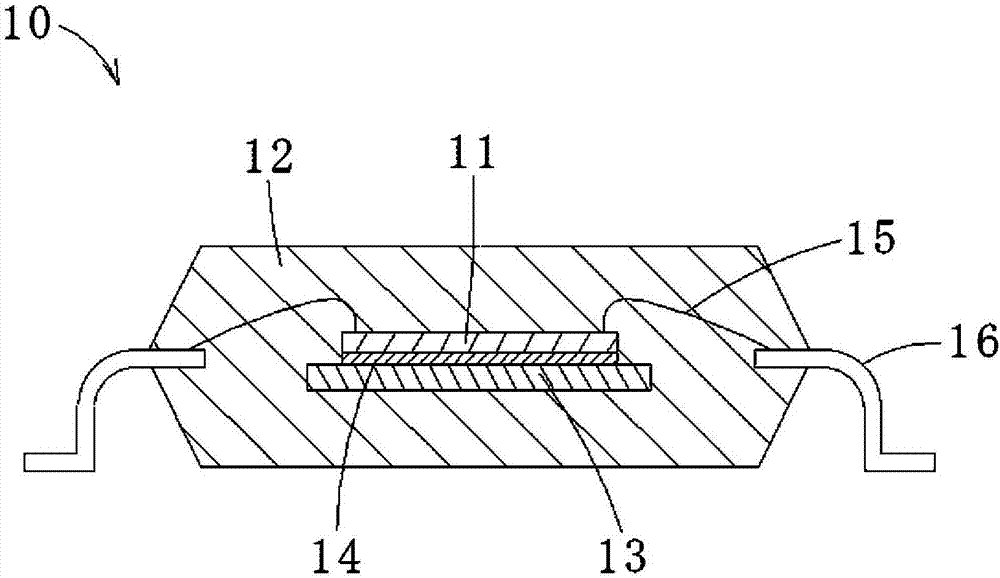

[0188] Mount the TEG (Test Element Group) chip (3.5mm×3.5mm) on a 352-pin BGA (the substrate is a bismaleimide-triazine resin / glass cloth substrate with a thickness of 0.56mm, and the package size is 30mm×30mm, thickness 1.17mm). Next, using a copper wire (copper purity: 99.99% by mass, diameter: 25 μm), wire bonding was performed on the electrode pads with a wire pitch of 80 μm.

[0189] Using a low-pressure transfer molding machine ("Y series" manufactured by TOWA), the obtained sealing resin compositions of Examples and Comparative Examples were used under the conditions of a mold temperature of 175°C, an injection pressure of 6.9MPa, and a curing time of 2 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com