Chitosan nanometer micro-bubble and preparation method and application thereof

A chitosan nanometer and chitosan technology, which is applied in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc., can solve the problems of poor imaging effect, complicated preparation process of nano-microbubbles, and high cost. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of chitosan nano microbubbles, comprising the steps of:

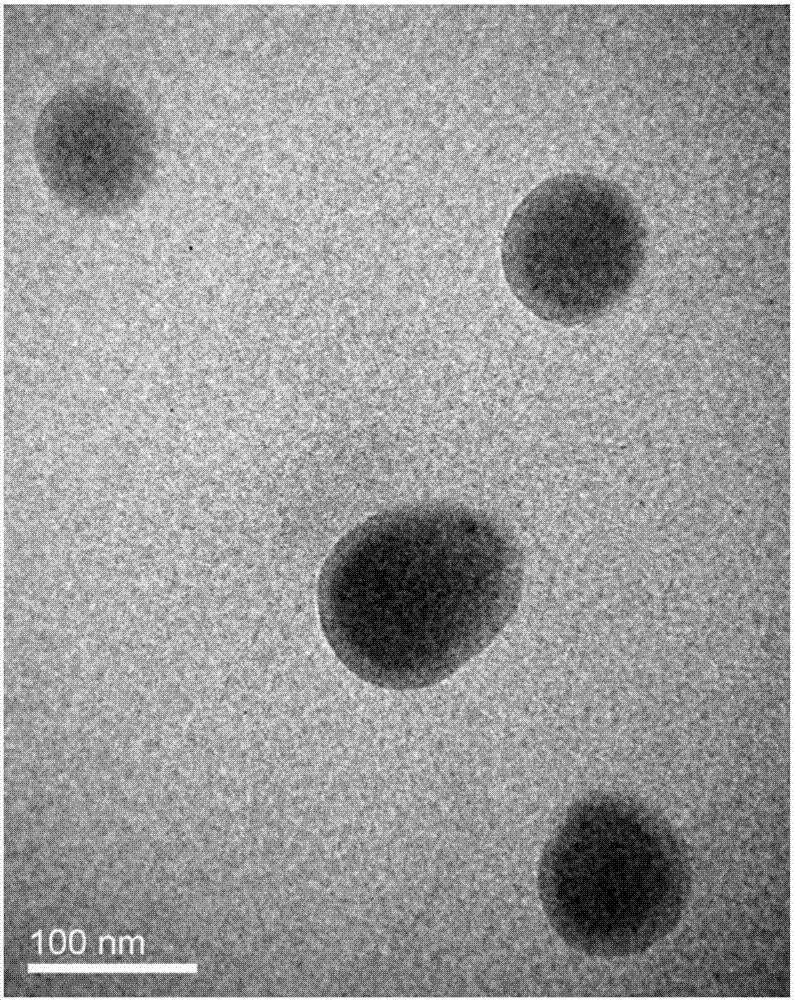

[0053](1) Prepare 50 mL of acrylic acid aqueous solution with a mass concentration of 0.44%, add chitosan, the chitosan mass (unit g) added is 1% of the volume (unit mL) of the acrylic acid aqueous solution, stir until completely dissolved, and heat under nitrogen protection To 75°C, add 70 mg of potassium persulfate, react for about 1 hour, set the temperature to 60°C, continue the reaction for 80 minutes, then filter the product to remove impurities, then pour it into a dialysis bag, and then place it in acetic acid with pH=4.5- In sodium acetate buffer solution, magnetically stirred for 24 hours, dialyzed to remove impurities, then taken out, added 0.078g of glutaraldehyde, heated to 40°C for reaction, after 2 hours, the reaction was completed, and a nanoparticle suspension was prepared, with a particle size of about 100nm , and has a hollow structure, its shape is observed by transmission...

Embodiment 2

[0056] A preparation method of chitosan nano microbubbles, comprising the steps of:

[0057] (1) Prepare 50 mL of an acrylic acid solution with a mass concentration of 0.22%, add chitosan, the chitosan mass (unit g) added is 0.5% of the volume (unit mL) of the acrylic acid aqueous solution, stir until completely dissolved, and heat under nitrogen protection To 75°C, add 45 mg of potassium persulfate, react for about 1 hour, set the temperature to 60°C, after 100 minutes, filter the product to remove impurities, then pour it into a dialysis bag, and place it in acetic acid-sodium acetate buffer at pH=4.5 In the liquid, take it out after magnetic stirring for 24 hours, add 0.035g of glutaraldehyde, and heat to 40°C for reaction. After 2 hours, the reaction is completed, and the nanoparticle suspension is obtained. The particle size of the nanoparticle is about 100nm and has a hollow structure. form and figure 1 similar.

[0058] (2) Add lactose to the nanoparticle suspension p...

Embodiment 3

[0060] A preparation method of chitosan nano microbubbles, comprising the steps of:

[0061] (1) Prepare 50 mL of acrylic acid solution with a mass concentration of 0.44%, add chitosan, the quality of chitosan added (in g) is 1% of the volume of acrylic acid aqueous solution (in mL), heat to 70°C under nitrogen protection, add 60mg of potassium persulfate, react for about 1 hour, set the temperature to 60°C, filter the product after 80 minutes to remove impurities, then pour it into a dialysis bag, put it in acetic acid-sodium acetate buffer solution with pH=4.5, and stir it magnetically for 24 hours Take it out, add 0.078g of glutaraldehyde, heat to 40°C for reaction, after 2h, the reaction is complete, and a nanoparticle suspension is obtained. The particle size of the nanoparticle is about 100nm and has a hollow structure. figure 1 similar.

[0062] (2) Add mannitol to the nanoparticle suspension prepared in step (1), the quality (unit g) of mannitol is 5% of the volume (u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com