A modification method of cation exchange resin and method for preparing methyl tert-amyl ether

An ion exchange resin and cation exchange technology, applied in the field of modification of cation exchange resin, can solve the problems of increased oligomerization side reactions, increased by-products, corroded equipment, etc., to improve stability, increase specific surface area, and reduce loss rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

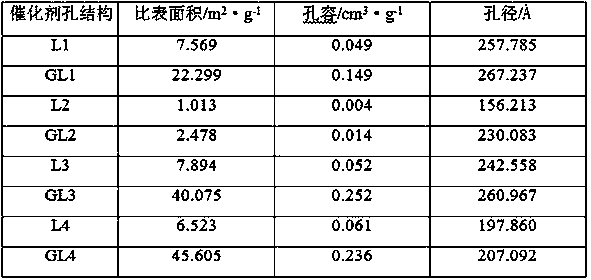

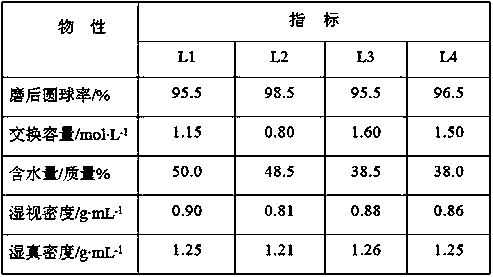

Embodiment 1

[0049] Soak the commercially available DNW-type sulfonic acid-based cation exchange resin produced by Dandong Mingzhu Special Resin Co., Ltd. in toluene at 40°C for 28 hours, and then soak it in methyl isobutyl ketone at 50°C for 40 hours after filtering. After washing and drying, the volume ratio of toluene or methyl isobutyl ketone to sulfonic acid cation exchange resin is 10:1. Take 500ml of the above catalyst, put it in 3mg / L deoxygenated water, 3 Inject nitrogen at a flow rate, soak for 16 hours at a pressure of 0.6MPa and a temperature of 65°C; then adjust the nitrogen flow rate to 15m 3 / h, increase the pressure to 1.0MPa, soak at 90°C for 18h; then adjust the nitrogen flow rate to 5m 3 / h, the pressure was raised to 1.5MPa, the temperature was raised to 140°C and soaked for 24 hours, and after the treatment, the modified sulfonic acid-based cation exchange resin GL1 was obtained by washing and drying.

Embodiment 2

[0051] Other conditions are the same as in Example 1, except that the DNW-type sulfonic acid-based cation-exchange resin is changed into DZH-type sulfonic-acid-based cation-exchange resin GL2.

Embodiment 3

[0053] Other conditions are the same as in Example 1, except that the DNW type sulfonic acid cation exchange resin is changed to D005-II type sulfonic acid cation exchange resin GL3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com