Low-cost high-performance caulking adhesive and preparation method thereof

A caulking and high-performance technology, applied in the field of engineering caulking, can solve the problems of high production cost and other problems, and achieve the effects of stable performance, high aromatic content, and excellent high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

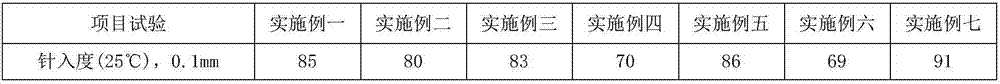

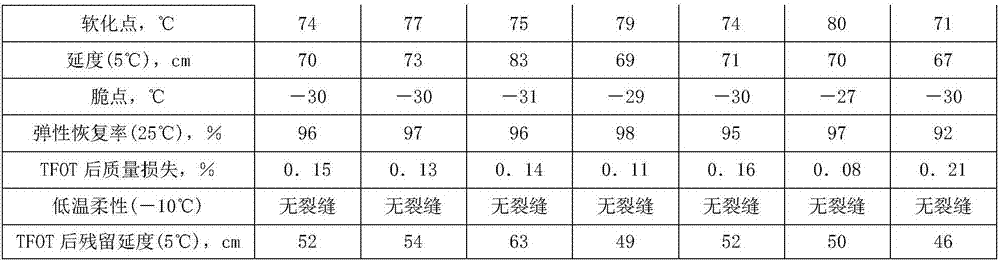

Examples

Embodiment 1

[0036] Taking the production of 500 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0037] Catalytic oil slurry: 350 grams, produced by Maoming Petrochemical

[0038] Rubber powder: 115 grams, recycled waste rubber powder produced by Lingzhong Composite Materials Company, fineness=60 mesh

[0039] Hard asphalt: 35 grams, recycled waste road asphalt produced by Road Recycling Company, penetration = 31

[0040] First heat the catalytic oil slurry to 120°C and then pour it into a high-speed shearing machine, and keep the temperature at 120°C. Divide the rubber powder into 3 parts, the first and second parts are 40 grams respectively, and the third part is 35 grams. First, slowly pour the first rubber powder into the high-speed shearing machine and carry out circular shearing together with the catalytic oil slurry. When the first After the first part of rubber powder is completely mixed with the catalytic o...

Embodiment 2

[0042] Taking the production of 500 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0043] Catalytic oil slurry: 300 grams, produced by Maoming Petrochemical

[0044] Rubber powder: 160 grams, recycled waste rubber powder produced by Lefeng Renewable Materials Company, fineness=40 mesh

[0045]Hard asphalt: 40 grams, recycled waste and aged asphalt produced by Zhitong Materials Company, penetration = 34

[0046] First heat the catalytic oil slurry to 125°C and then pour it into a high-speed shearing machine, and keep the temperature at 125°C. Divide the rubber powder into 4 parts, 40 grams each, first slowly pour the first part of the rubber powder into the high-speed shearing machine and carry out circular shearing together with the catalytic oil slurry, when the first rubber powder is completely mixed with the catalytic oil slurry , then continue to add the second part of rubber powder for circular sh...

Embodiment 3

[0048] Taking the production of 500 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0049] Catalytic oil slurry: 325 grams, produced by Maoming Petrochemical

[0050] Rubber powder: 138 grams, recycled waste rubber powder produced by Lingzhong Composite Materials Company, fineness=60 mesh

[0051] Hard asphalt: 37 grams, recycled waste and aged asphalt produced by Zhitong Materials Co., Ltd., penetration = 34

[0052] First heat the catalytic oil slurry to 120°C and then pour it into a high-speed shearing machine, and keep the temperature at 120°C. Divide the rubber powder into 4 parts. The first to third parts are 40 grams respectively, and the fourth part is 18 grams. After the first part of rubber powder is completely mixed with the catalytic oil slurry, continue to add the second part of rubber powder for cyclic shearing. When the second part of rubber powder is completely mixed with the catalytic o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com