Device and method for coupling straw degradation and biogas slurry filtering

A coupling device and lifting device technology, which is applied in the field of straw degradation and biogas slurry filtration coupling device, can solve the problems of waste of agricultural and forestry waste resources, environmental pollution, etc., and achieve the effect of reducing manpower and material resources and facilitating loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

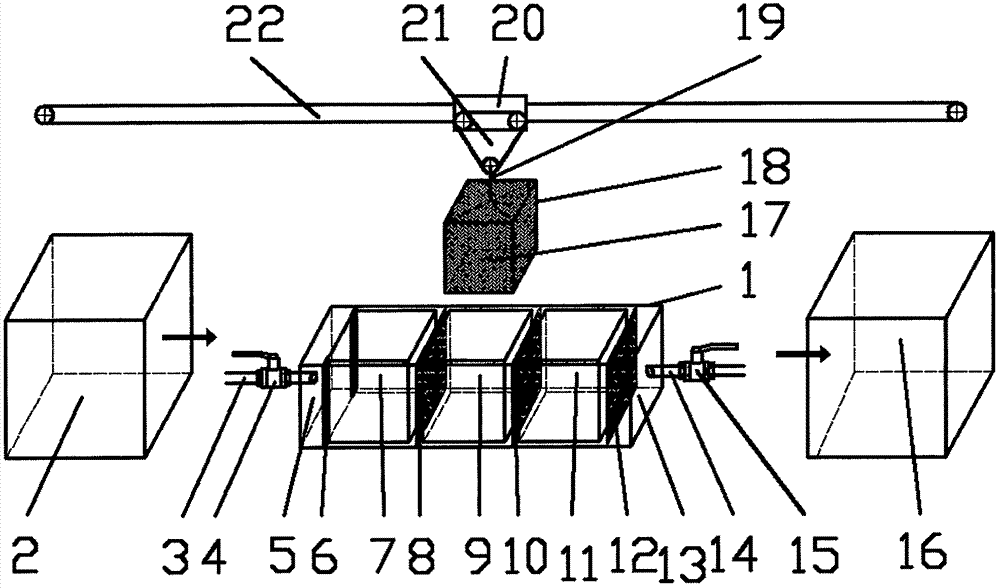

[0024] A straw degradation and biogas slurry filtration coupling device and method include a straw pre-treatment chamber 2, a biogas slurry filter tank housing 1, a horizontal moving lifting device, and a straw post-treatment chamber 16;

[0025] The left end of the biogas slurry filter housing 1 is provided with a biogas slurry raw liquid input pipe 3, and the right end is provided with a biogas slurry filtrate output pipe 14, and a baffle 6, a straw filter tank and a filter screen are arranged inside;

[0026] Both the straw filter tank and the filter screen are provided with a three-stage filtration program and the filtration level is increased in turn; the biogas slurry raw liquid input pipe 3 and the filtrate output pipe 14 are equipped with pipeline valves;

[0027] The horizontal moving lifting device is provided with a horizontal moving device 20 and a vertical lifting device 21, and the lower end is connected with a square charging shell 18 through a traction rope 19; ...

Embodiment 2

[0034] The structure of the present invention mainly includes a straw pre-treatment room 2, a biogas slurry filter tank housing 1, a horizontal moving lifting device, and a straw post-treatment room 16. The straw raw materials of large tubers are crushed in the straw pre-treatment room 2 to obtain 3-5 cm The small tuber straw material 17 between them is put into the square charging shell 18, and the square charging shell 18 connected with the traction rope 19 is transported to the designated first-level straw filtering through the horizontal moving device 20 and the vertical lifting device 21. In the pool 7, the secondary straw filter pool 9, and the third-stage straw filter pool 11, the baffles 6 are fixed on both sides of the primary straw filter pool 7 before filtering. When biogas slurry is filtered, open the biogas slurry raw liquid input pipeline valve 4 so that the biogas slurry raw liquid flows from the biogas slurry raw liquid input pipe 3 into the biogas slurry raw li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com