A Method to Prevent Input Errors of Tool Setting Value and Tool Compensation Value in NC Machining

A tool compensation and input error technology, applied in the direction of digital control, electrical program control, etc., can solve problems such as tool and tool compensation value input errors, and achieve the effect of reducing actions, reducing risks and labor intensity, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

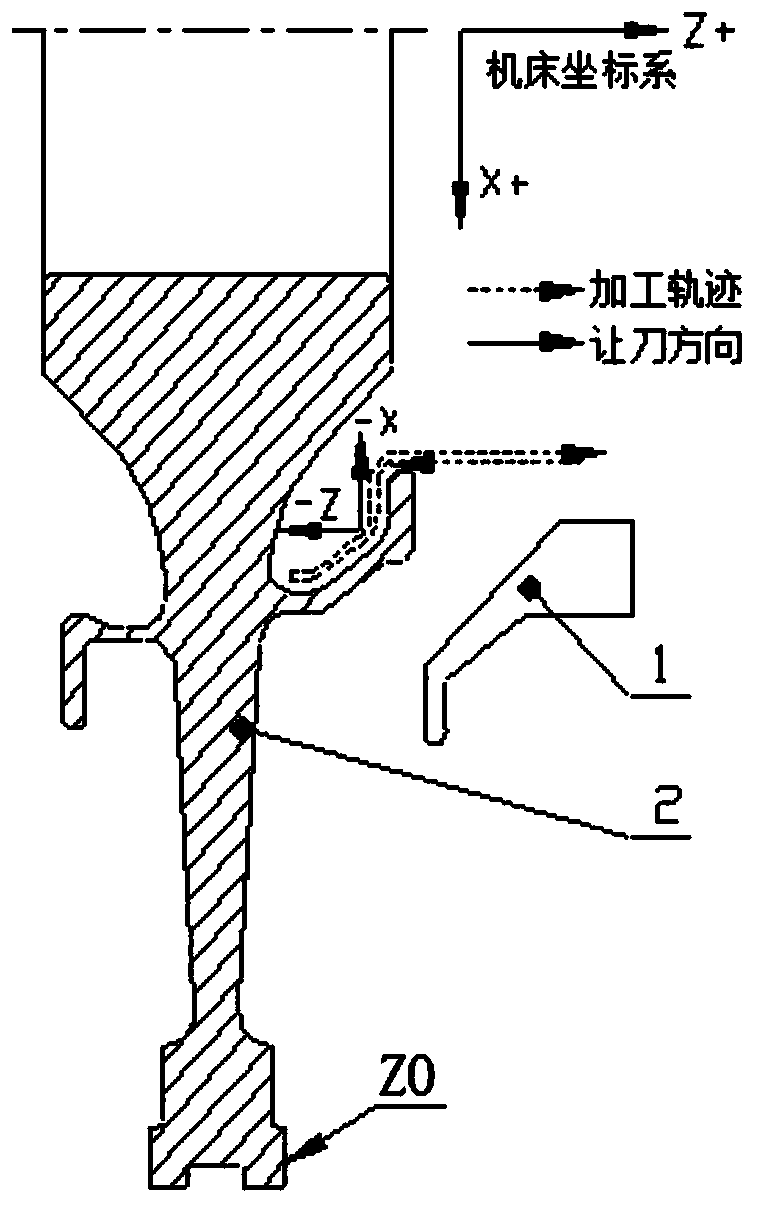

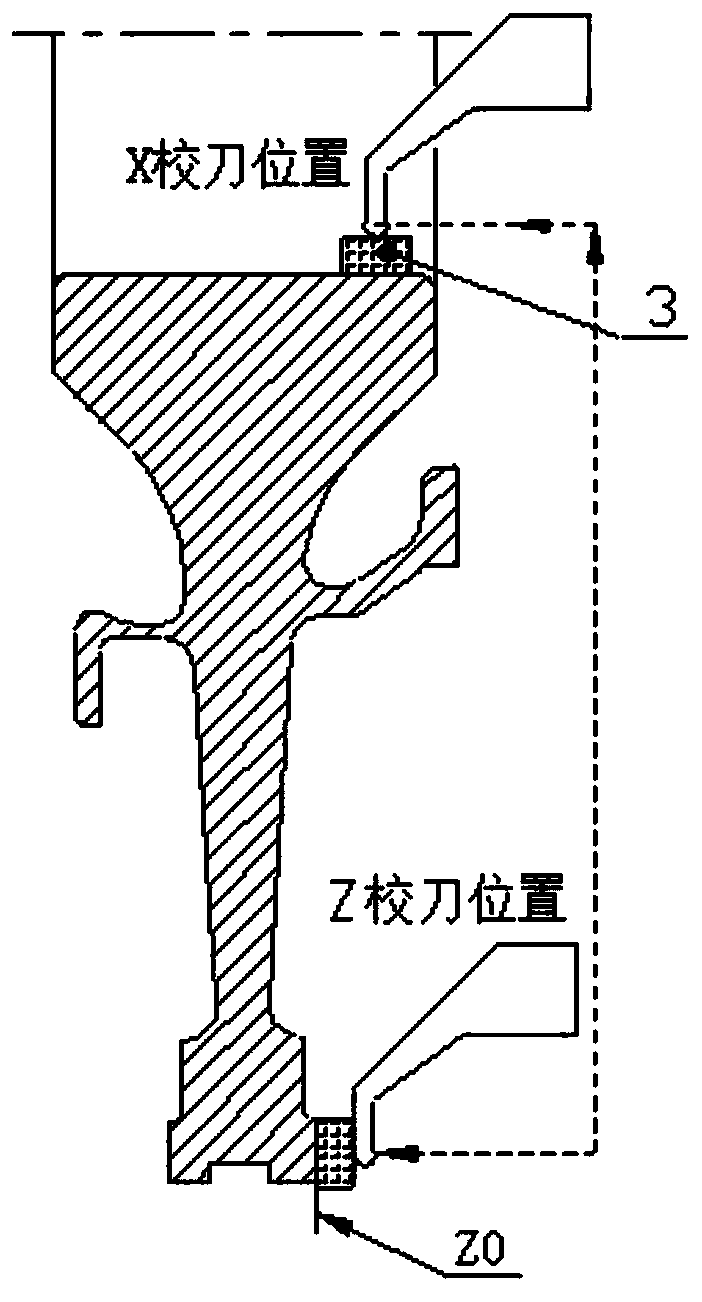

[0057] attached to figure 1 The cavity of the part shown is designed by the Siemens control system for the anti-mistake program of the turning process.

[0058] attached figure 1 The middle processing part is a part of the surface inside the cavity, the wall thickness tolerance of the right end surface is ±0.02mm, the tolerance of the left diameter is ±0.075mm, and the tolerance of the slope surface is ±0.1mm. The tool used is an elbow groove cutter. Due to the narrow size of the cutter head, considering its rigidity, there will be a certain amount of tool clearance during processing. The tool compensation direction and tool compensation amount follow the following principles: it is allowed to give the tool in the direction where there is no material, that is, no cutting, and the tool amount should not be too large, and must match the allowance. At the same time, the back of the tool must not interfere with the part. Therefore, the tool clearance direction in the X direction...

Embodiment 2

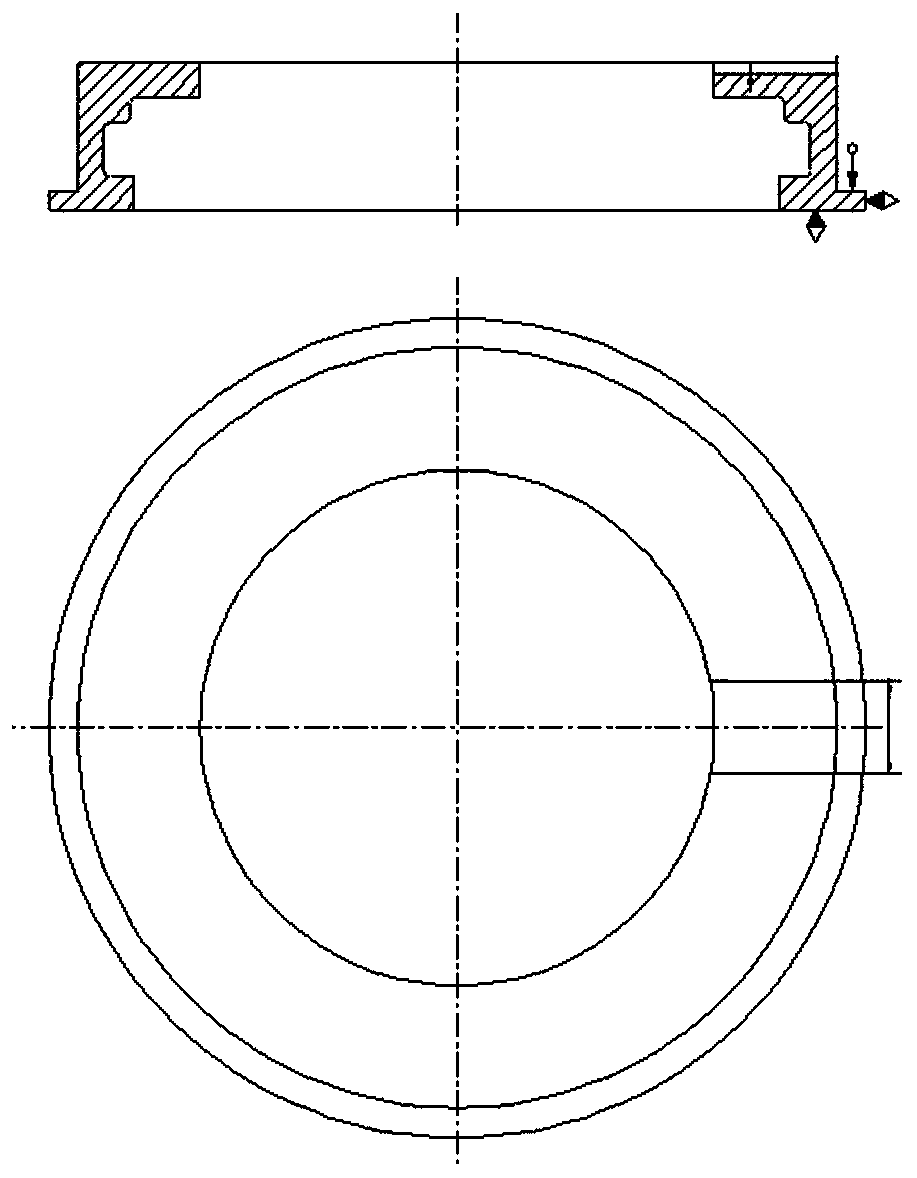

[0067] attached to image 3 The FANUC control system anti-error program design is carried out on both sides of the fine milling end face groove of the part shown.

[0068] Use the milling cutter 6 to process both sides of the end face groove, the cutter diameter is In order to ensure the surface roughness, the down milling method is selected for processing, and the G42 command is used for programming. The groove width tolerance of the part is〖24〗_0^(+0.05)mm. Considering the tool side edge wear, the minimum radius compensation is allowed to Since the margin on one side of the groove width after rough machining is 0.5mm, the maximum radius compensation is allowed up to The correct tool compensation range is Assign values to #511 and #512 variables in the program. The groove depth is The margin at the bottom of the groove is 0.5mm, so the correct tool compensation range of the Z axis should be [-0.025,0.5], assign values to #513 and #514 variables in the program, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com