Centralized Scheduling Method for CNC Machine Tools in Processing Workshops in Case of Emergency Adding Orders

A technology of CNC machine tools and processing workshops, applied in the direction of comprehensive factory control, electrical program control, etc., can solve problems such as unstable production and failure to consider stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

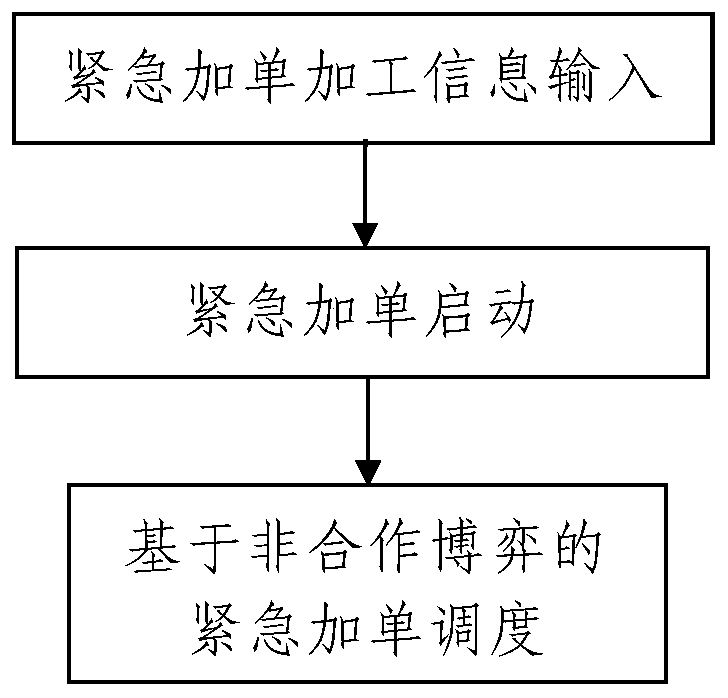

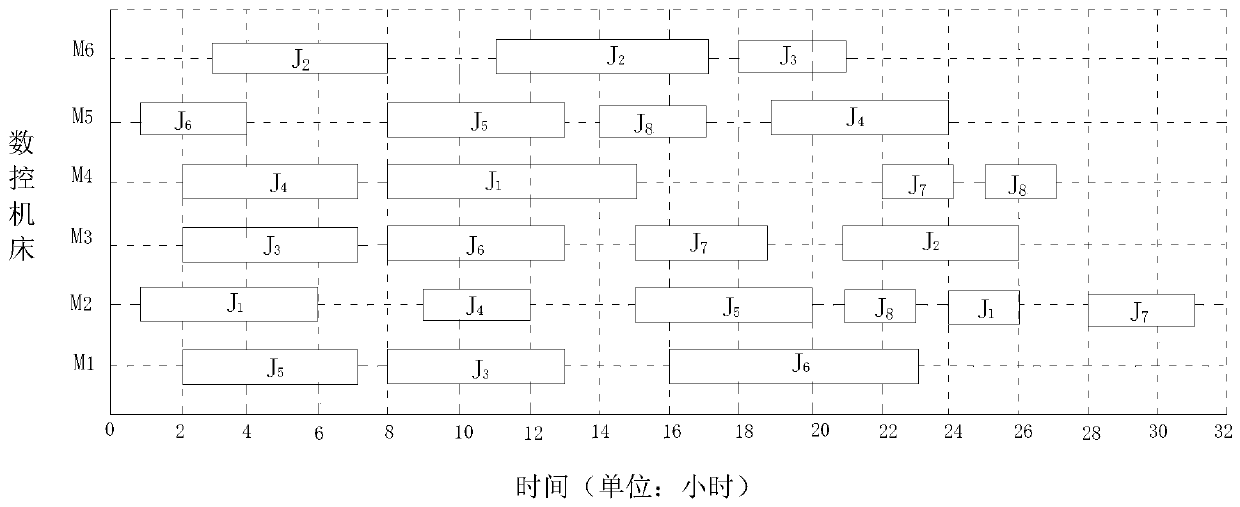

[0088] Such as figure 1 The shown method for centralized scheduling of CNC machine tools in a processing workshop in the case of an emergency order addition includes the following steps:

[0089] Step 1: Input of emergency order processing information: input the emergency order processing information by using a parameter input device connected to the dispatch controller, and synchronously record the input emergency order processing information through the dispatch controller;

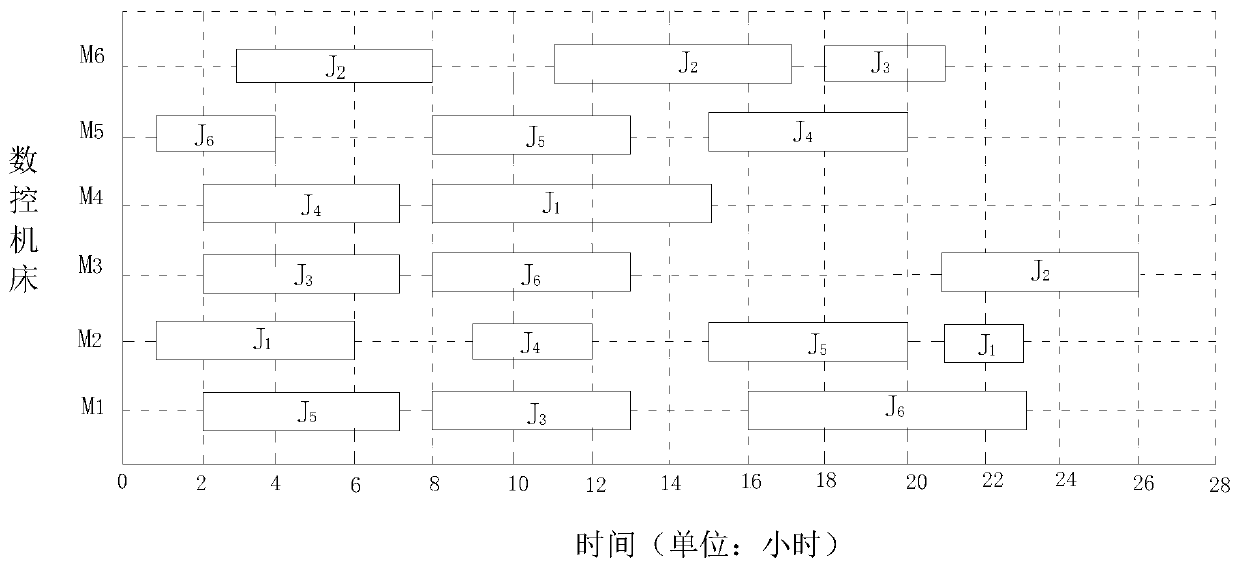

[0090] The scheduling controller is a controller for scheduling N numerically controlled machine tools located in a processing workshop, N is the total number of numerically controlled machine tools in the processing workshop, N is a positive integer and N≥5; the scheduling controller is connected with The machine tool controllers of the N numerical control machine tools are connected; the numbers of the N numerical control machine tools are respectively denoted as M 1 , M 2 ,..., M N ;

[0091] In this step,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com