Physical purification method for recycling positive powder from lithium ion battery

A lithium-ion battery and physical purification technology, which is applied in the field of physical purification of lithium-ion battery recovery positive electrode powder, can solve the problem of the reduction of the effective recovery rate of aluminum purity positive electrode powder, increasing the difficulty of separating positive electrode powder by physical methods, and the recycling of waste batteries The rate is less than 2%, and achieve the effect of low cost, improved recovery rate, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

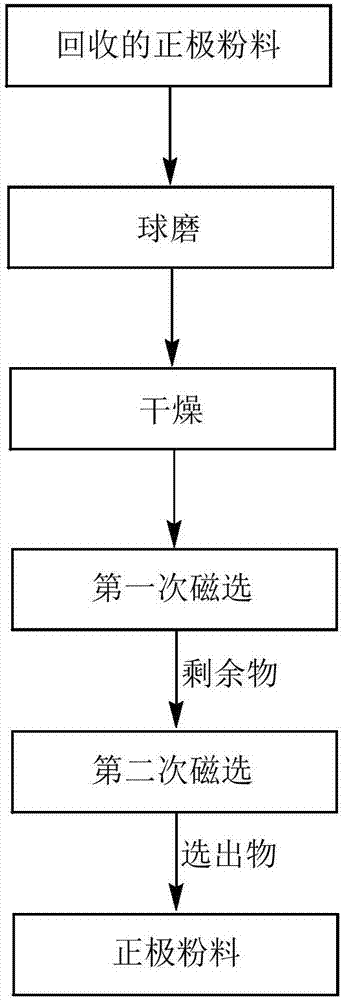

[0020] The physical purification method of lithium ion battery recovery positive electrode powder of the present embodiment comprises the following steps:

[0021] 1) Dry the recovered positive electrode powder of lithium iron phosphate lithium ion battery at 120°C for 30 minutes; then ball mill it at a speed of 300r / min for 0.5h to obtain positive electrode powder with a particle size of 50-100μm;

[0022] 2) The positive electrode powder after ball milling in step 1) is subjected to the first magnetic separation with a magnetic field whose magnetic induction intensity is 3000Gs, and the selected matter is removed to obtain the remaining powder;

[0023] 3) Use a magnetic field with a magnetic induction intensity of 8000Gs to perform a second magnetic separation on the remaining powder, and collect the selected material to obtain the product.

[0024] The purity of the positive electrode powder obtained by using the physical purification method for recovering the positive ele...

Embodiment 2

[0026] The physical purification method of lithium ion battery recovery positive electrode powder of the present embodiment comprises the following steps:

[0027] 1) Dry the recovered lithium manganate lithium ion battery positive electrode powder at 150°C for 30 minutes; then ball mill it at a speed of 200r / min for 1 hour to obtain positive electrode powder with a particle size of 50-100 μm;

[0028] 2) The positive electrode powder after ball milling in step 1) is subjected to magnetic separation for the first time using a magnetic field with a magnetic induction intensity of 2500Gs, and the selected material is removed to obtain the remaining powder;

[0029] 3) Use a magnetic field with a magnetic induction intensity of 8000Gs to perform a second magnetic separation on the remaining powder to collect the selected material;

[0030] 4) Carry out magnetic separation to the residue after the second magnetic separation by using a magnetic field whose magnetic induction intens...

Embodiment 3

[0034] The physical purification method of lithium ion battery recovery positive electrode powder of the present embodiment comprises the following steps:

[0035] 1) Dry the recovered lithium cobaltate lithium-ion battery cathode powder at 135°C for 30 minutes; then ball mill it at a speed of 300r / min for 0.2h to obtain the cathode powder with a particle size of 50-100μm;

[0036] 2) The positive electrode powder after ball milling in step 1) is subjected to the first magnetic separation using a magnetic field with a magnetic induction intensity of 3500Gs, and the selected material is removed to obtain the remaining powder;

[0037] 3) Use a magnetic field with a magnetic induction intensity of 10000Gs to perform a second magnetic separation on the remaining powder, and collect the selected material;

[0038] 4) Using a magnetic field with a magnetic induction intensity of 12000Gs to perform magnetic separation on the positive electrode powder selected in step 3), the selecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com