Efficient live earthworm separating method and device for implementing method

A technology of living earthworms and separation method, which is applied in animal husbandry and other fields, can solve the problems of large site occupation, reduced production efficiency, and no practical value, and achieve the effects of reducing site occupation, improving practicability and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An efficient live earthworm separation method, comprising the following steps:

[0046] 1) The material containing live earthworms is packed into a separation container;

[0047] 2) Sprinkling water above the material containing live earthworms in step 1), so that the water content of the material reaches 70% to 90%;

[0048] In this embodiment, in step 2), water is sprayed in the form of spray or spray, thereby making the water distribution in the material more uniform, and further enabling the living earthworms at various positions in the material pile to be separated to the greatest extent.

[0049] Spraying an appropriate amount of water over the container in the form of a spray or shower has the following beneficial effects:

[0050] (1) Forming a short-term high-water environment, prompting earthworms to drill into the interior of the material quickly, and separating impurities on the surface of the material;

[0051] (2) The water sprayed many times will contin...

Embodiment 2

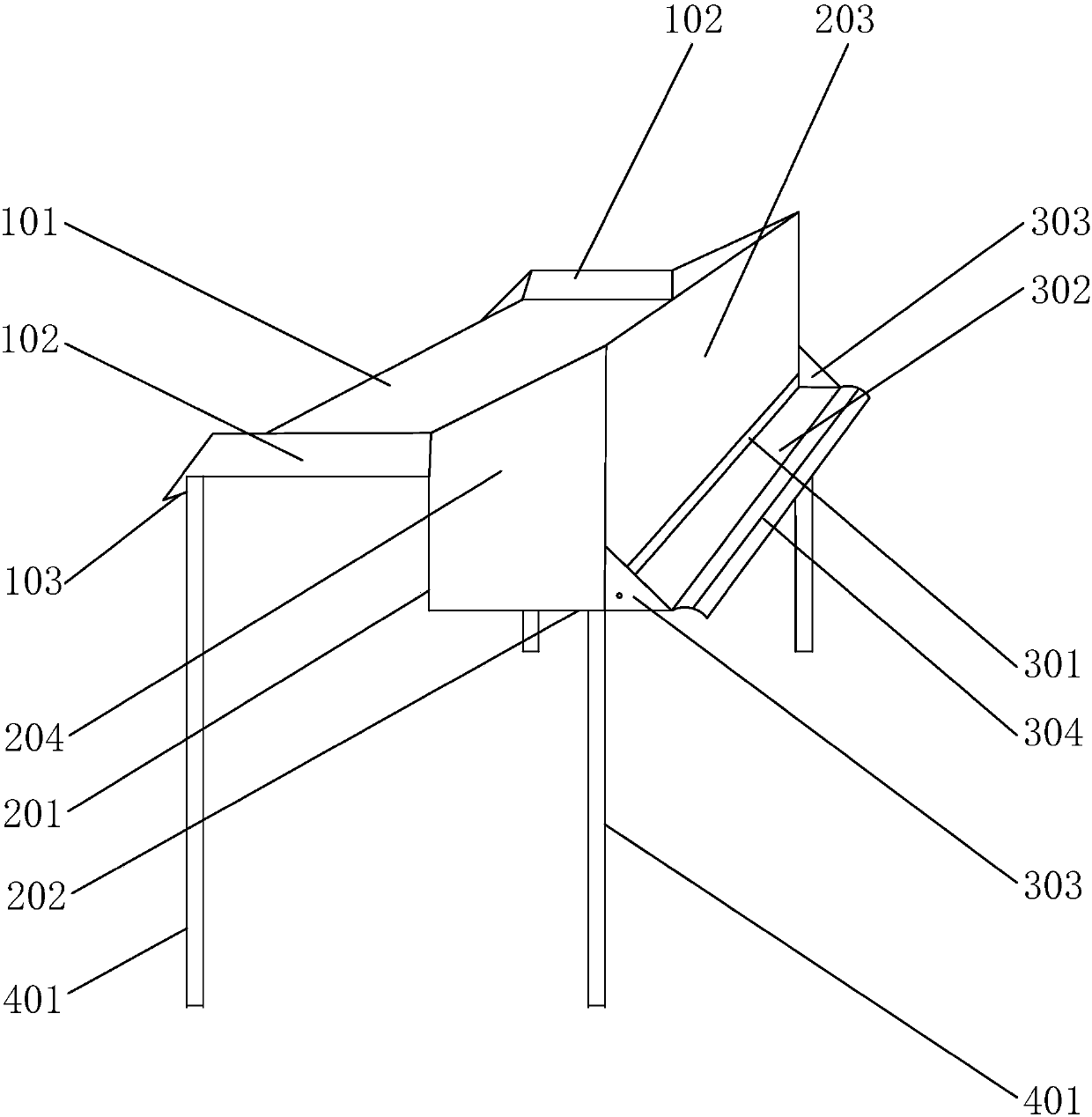

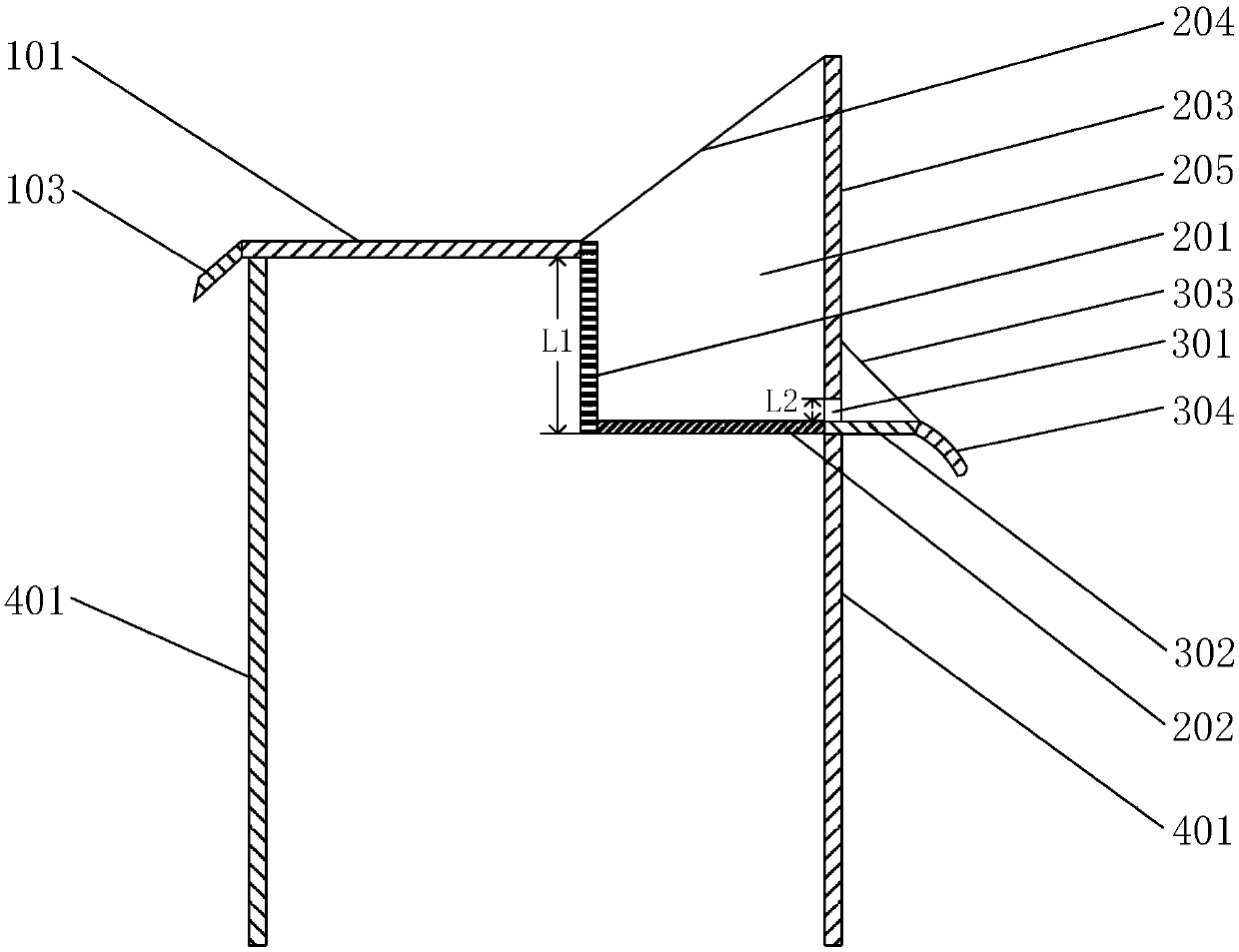

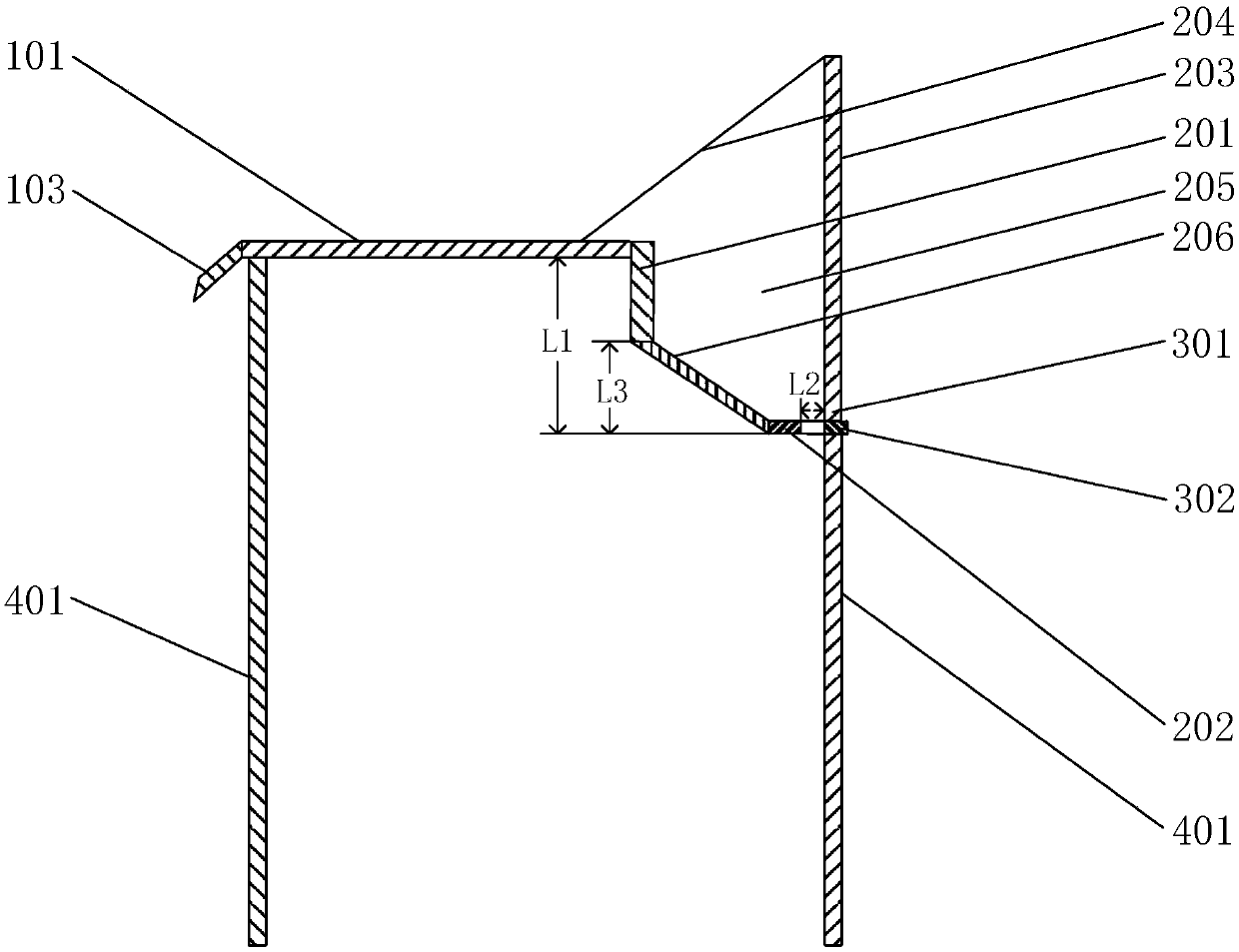

[0077] Based on the efficient live earthworm separation method in Embodiment 1, this embodiment provides a live earthworm separation device for realizing the above method, including an operation unit, a separation unit and a collection unit, and also includes a separation unit arranged under the operation unit. The support feet below and / or below the collection unit; the separation device composed of the operation unit, the separation unit and the collection unit meet the requirements for the separation container in the above method.

[0078] The operation unit includes an operating horizontal plate, an operating baffle and a tilting slope. The impurity recovery container can also be placed on the ground below the tilting slope to pick up the impurities coming out of the tilting slope; there are 2 operating baffles; the tilting slope It is connected with two operation baffles to the three sides of the operation horizontal plate respectively.

[0079]The separation unit include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com