Extracting technology of flavone of ageratum conyzoides by using response surface methodology and application thereof

A technology of flavonoids and extraction process of Agonythistle, which is applied in the field of optimizing the extraction process of flavonoids of Agonychus thistle, which can solve the problem of lingering, little research on the medicinal effect of Agonychus, and no antioxidation of flavonoids of Agaricus effect research and other issues, to achieve the effects of low cost, low purification difficulty, free radical scavenging and strong antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

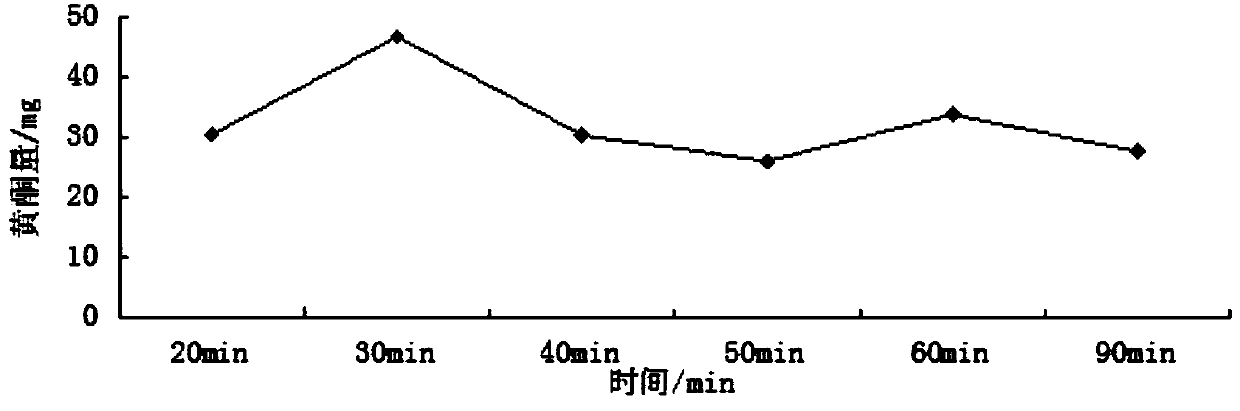

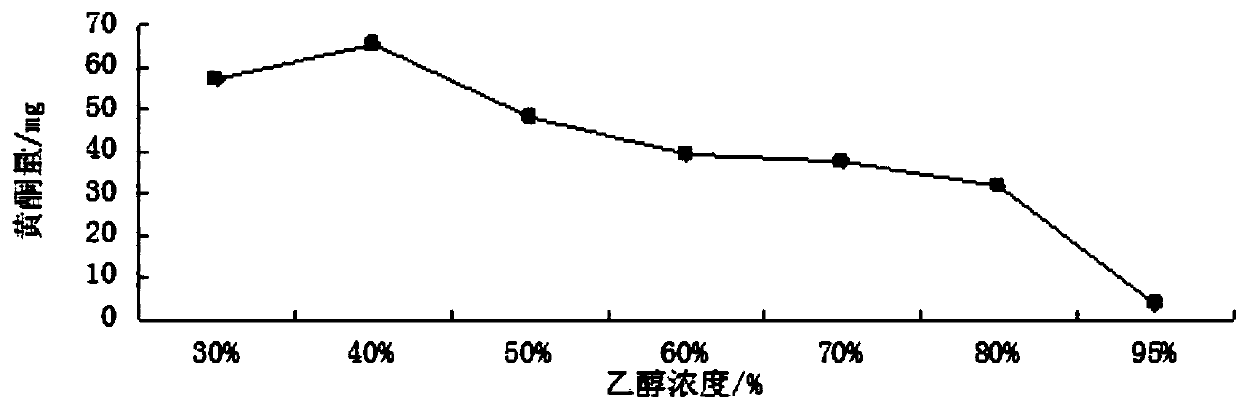

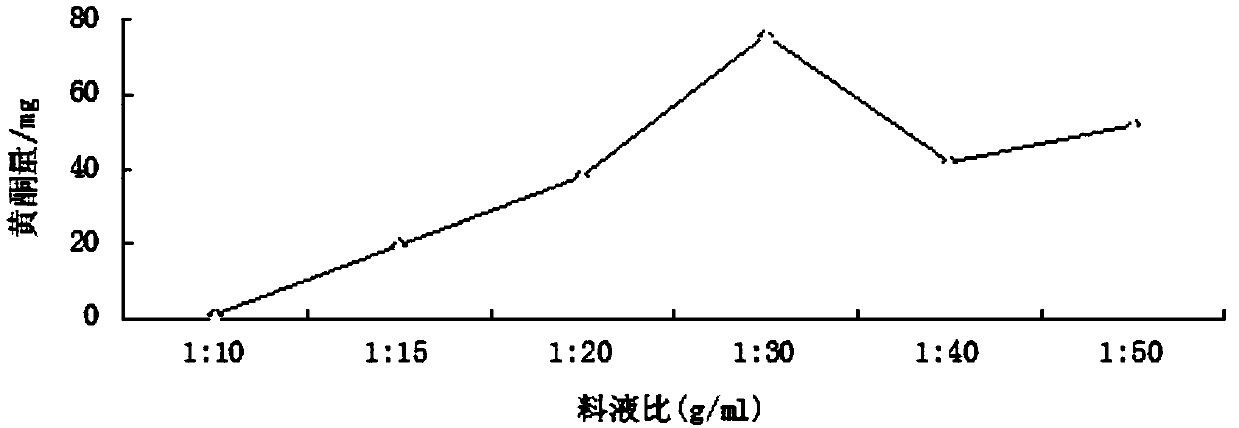

[0043] A response surface method was used to optimize the extraction process of ageratum flavonoids. According to the principle of Box-Behnken experiment design, Design-Expert software was used to design and optimize the process conditions of extracting ageratum flavonoids such as ethanol concentration, extraction time, solid-liquid ratio, and extraction times. Ultrasonic-assisted extraction of ageratum flavonoids comprises the following process steps:

[0044] S1: Dried the whole plant of Ageratum thistle naturally under a cool condition, crushed it and passed it through a 60-mesh sieve, and weighed 2.0 g of Ageratum thistle powder for later use;

[0045] S2: Put the Ageratum powder into the extraction tank, add 48% ethanol solution, the ratio of solid to liquid is 1:40, cold soak for 24 hours, and shake well every 2 hours;

[0046] S3: Ultrasonic extraction is carried out on the ageratum powder after cold soaking, the temperature of the liquid during extraction is controlled...

Embodiment 2

[0049] A response surface method was used to optimize the extraction process of ageratum flavonoids. According to the principle of Box-Behnken experiment design, Design-Expert software was used to design and optimize the process conditions of extracting ageratum flavonoids such as ethanol concentration, extraction time, solid-liquid ratio, and extraction times. Ultrasonic-assisted extraction of ageratum flavonoids comprises the following process steps:

[0050] S1: Dried the whole plant of Ageratum thistle naturally under a cool condition, crushed it and passed it through a 60-mesh sieve, and weighed 2.0 g of Ageratum thistle powder for later use;

[0051] S2: Put the Ageratum powder into the extraction tank, add 48% ethanol solution, the ratio of solid to liquid is 1:40, cold soak for 24 hours, and shake well every 2 hours;

[0052] S3: Ultrasonic extraction is carried out on the ageratum powder after cold soaking, the temperature of the liquid during extraction is controlled...

Embodiment 3

[0055] A response surface method was used to optimize the extraction process of ageratum flavonoids. According to the principle of Box-Behnken experiment design, Design-Expert software was used to design and optimize the process conditions of extracting ageratum flavonoids such as ethanol concentration, extraction time, solid-liquid ratio, and extraction times. Ultrasonic-assisted extraction of ageratum flavonoids comprises the following process steps:

[0056] S1: Dried the whole plant of Ageratum thistle naturally under a cool condition, crushed it and passed it through a 60-mesh sieve, and weighed 2.0 g of Ageratum thistle powder for later use;

[0057] S2: Put the Ageratum powder into the extraction tank, add 48% ethanol solution, the ratio of solid to liquid is 1:40, cold soak for 24 hours, and shake well every 2 hours;

[0058] S3: Ultrasonic extraction is carried out on the ageratum powder after cold soaking, the temperature of the liquid during extraction is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com