A preparation method for effectively oxidizing noble metals and improving their electrocatalytic performance

A noble metal and electrocatalytic technology, which is applied in the field of nanomaterials and electrochemical catalysis, can solve the problems of violating the development trend of materialization and the inability to realize the amount of precious metal platinum, so as to improve catalytic performance and catalytic efficiency, facilitate dispersion and adhesion, and inhibit The effect of merging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

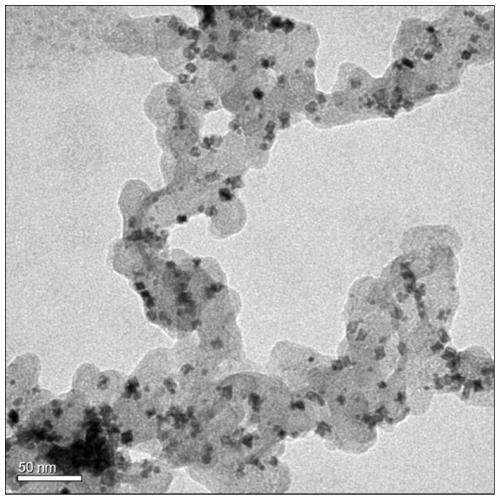

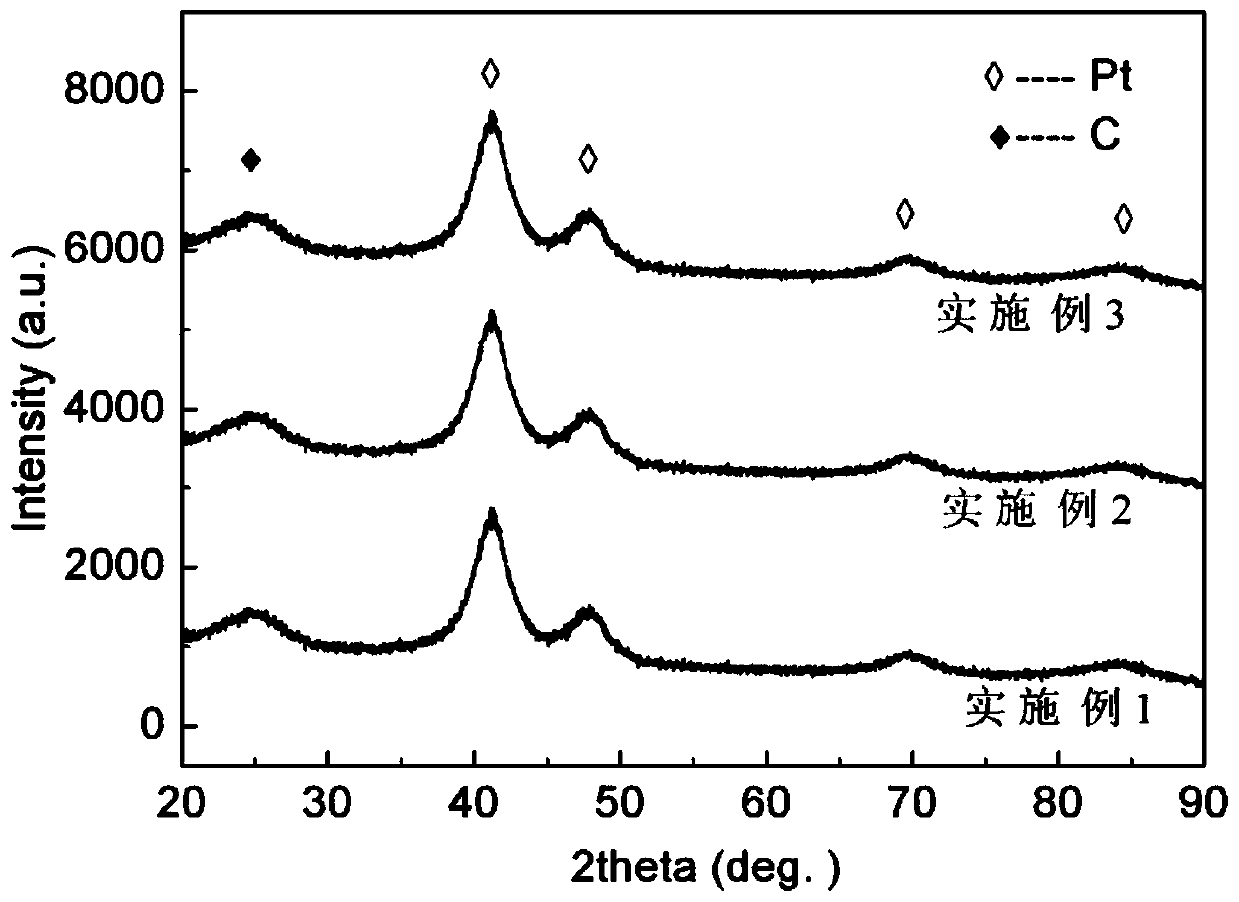

[0035] Platinum acetylacetonate (Pt(acac) 2 ), nickel acetylacetonate (Ni(acac) 2 ), ascorbic acid, N'N-dimethylformamide (DMF), and porous carbon as raw materials, the molar ratio of nickel to platinum is 1:4, and the amount of carbon added is 10wt. % calculation, excess ascorbic acid and DMF, and then use ultrasound to disperse for 0.5 hours, then carry out magnetic stirring treatment for 5 hours, the amount of DMF is 20mL, after the dispersion treatment, the mixed solution is placed in a 40mL reactor, and an oven is used at 2°C / min The heating rate was heated to 170°C, and the temperature was kept for 10 hours. After the heat preservation was completed, it was naturally cooled to room temperature, and then the product was collected by centrifugation at 5000 rpm for 15 minutes. The mixed solution of 4:1:1 was washed three times with liquid, and vacuum-dried at 50°C to obtain a powdered platinum-nickel alloy.

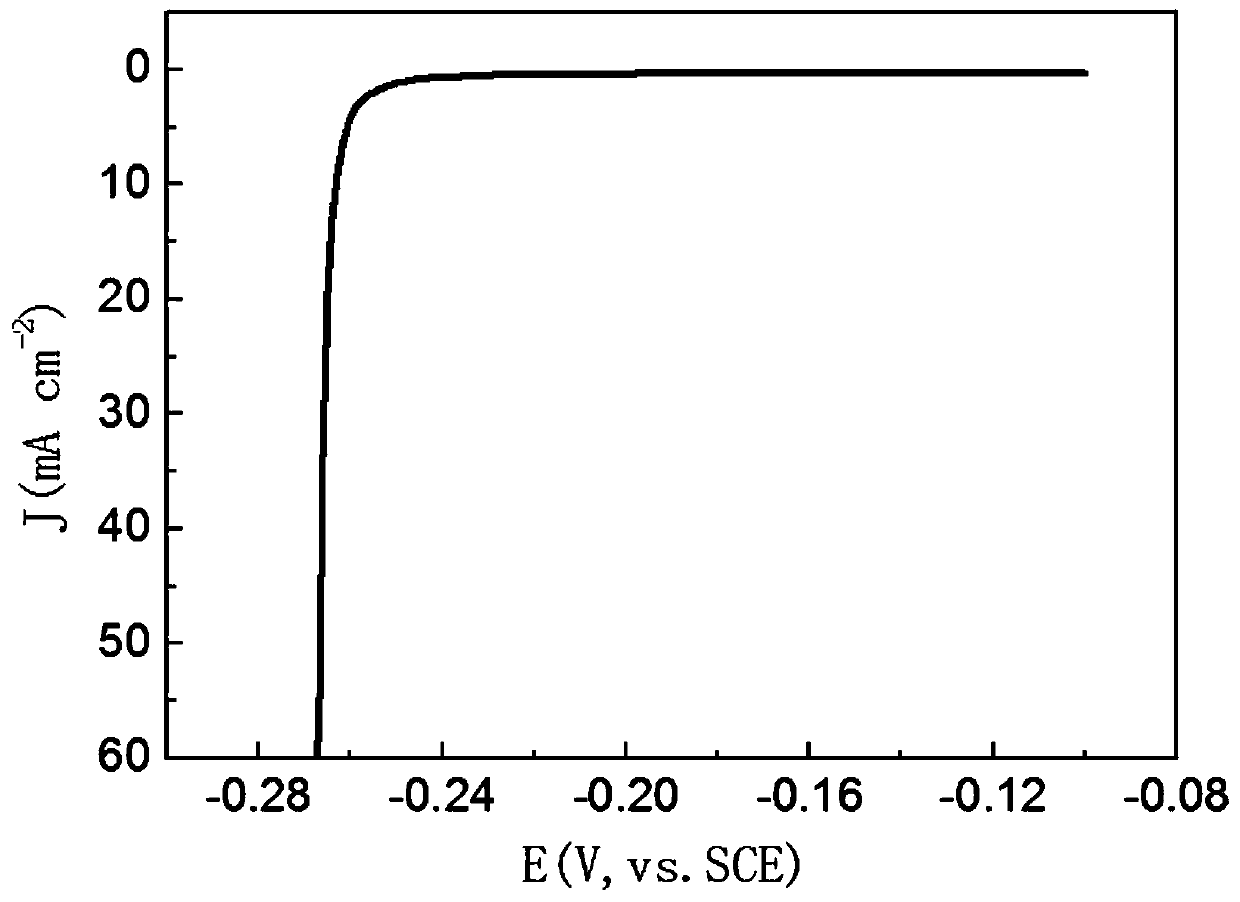

[0036] The obtained powdered platinum-nickel alloy was placed i...

Embodiment 2

[0039] Platinum acetylacetonate (Pt(acac) 2 ), cobalt acetylacetonate (Co(acac) 2 ), ascorbic acid, N'N-dimethylformamide (DMF), and porous carbon as raw materials, the molar ratio of cobalt to platinum is 1:3.5, and the amount of carbon added is 20wt. % calculation, excess ascorbic acid and DMF, and then use ultrasound to disperse for 1 hour, then carry out magnetic stirring treatment for 8 hours, the amount of DMF is 20mL, after the dispersion treatment, the mixed solution is placed in a 40mL reaction kettle, and an oven is used. The heating rate was heated to 200°C, and the temperature was kept for 7 hours. After the heat preservation was completed, it was naturally cooled to room temperature, and then the product was collected by centrifugation at 8000 rpm for 10 minutes. The mixed solution of 5:1:1 was washed 4 times, and vacuum-dried at 60° C. to obtain a powdered platinum-cobalt alloy.

[0040] The obtained powdery platinum-cobalt alloy was placed in a mixed solution ...

Embodiment 3

[0043] Platinum acetylacetonate (Pt(acac) 2 ), iron acetylacetonate (Fe(acac) 3 ), ascorbic acid, N'N-dimethylformamide (DMF), and porous carbon were mixed as raw materials, the molar ratio of iron to platinum was 1:3, and the amount of carbon added was 30wt. % calculation, excess ascorbic acid and DMF, and then use ultrasound to disperse for 2 hours, then carry out magnetic stirring treatment for 10 hours, the amount of DMF is 20mL, after the dispersion treatment, the mixed solution is placed in a 40mL reactor, heated to 220 °C in an oven, and kept For 4 hours, the heating rate was 8°C / min. After the heat preservation was completed, it was naturally cooled to room temperature, and then the product was collected by centrifugation at 10,000 rpm for 5 minutes. The mixed solution of 4:1:1 was washed three times, and vacuum-dried at 70°C to obtain a powdered platinum-iron alloy.

[0044] The obtained powdered platinum-iron alloy was placed in a mixed solution of 35% formic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com