PRB (permeable reactive barrier) repair material applied to repairing of underground water nitrate pollution and preparation method thereof

A repair material and nitrate technology are applied in the field of PRB repair material for repairing nitrate pollution of groundwater and its preparation field, which can solve the problems of carbon source loss, failure to achieve, increase the difficulty of repair technology and repair cost, etc. The effect of good field applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

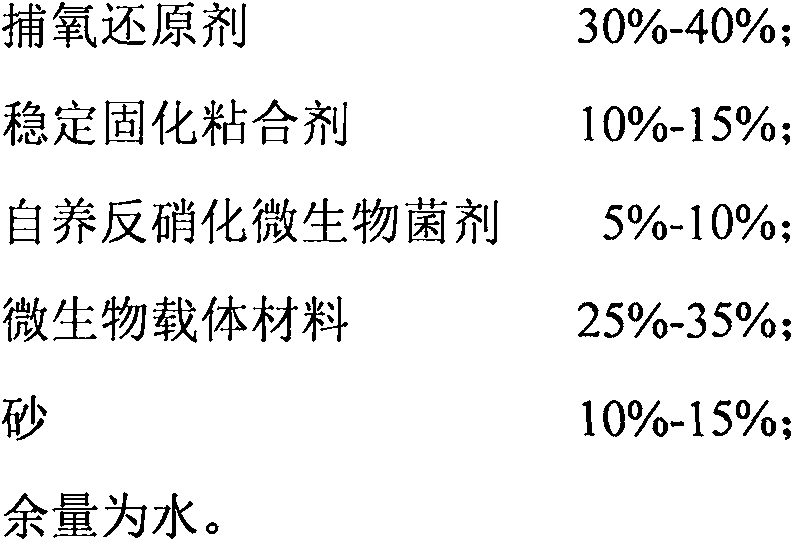

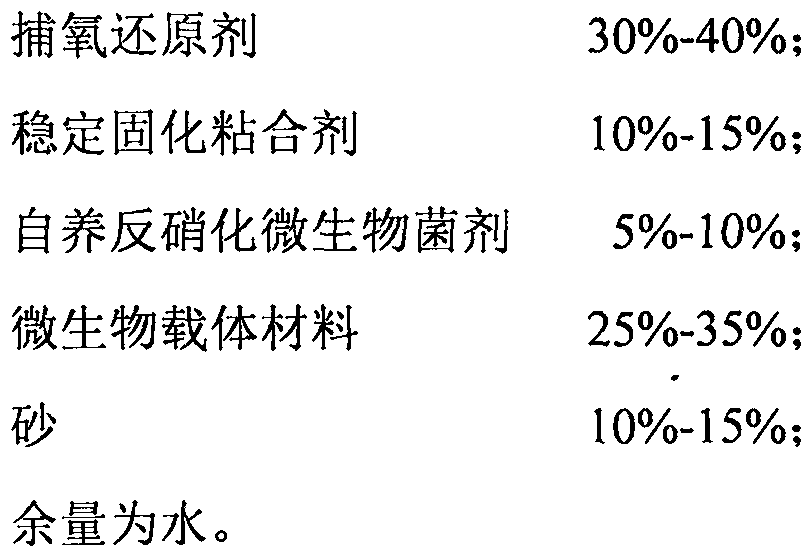

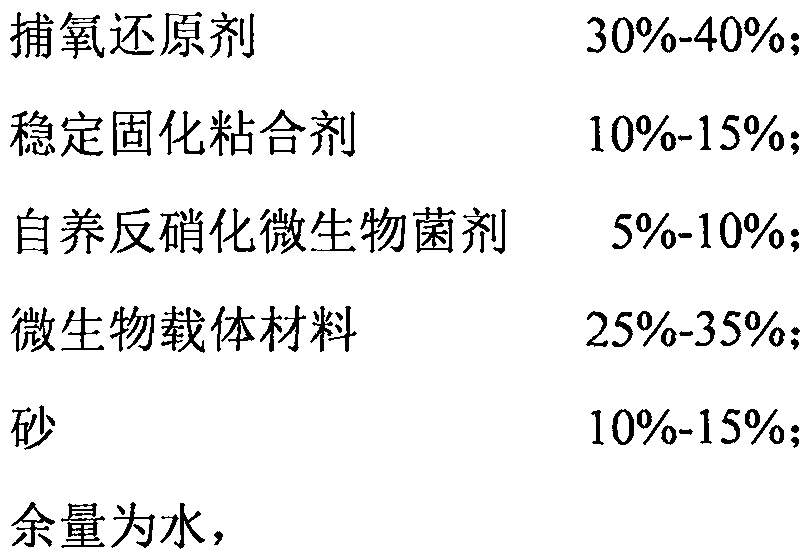

Method used

Image

Examples

Embodiment 1

[0022] Mix cement, fine sand and bentonite according to the mass ratio of 1:0.2-0.24:0.3-0.5 to prepare a stable and solidified adhesive, which is reserved for later use.

[0023] Take 700g of reducing iron powder, 200g of stable curing binder, 160g of autotrophic denitrifying microbial bacterial agent with elemental iron as the electron donor, 600g of zeolite and 240g of sand and mix them fully and evenly, spray quantitative water to make the mixture wet ;

[0024] Put the mixture into an extrusion spheronizer for granulation, and set the extrusion speed to be 50r / min, place it to dry under natural ventilation, and the particles with a particle size of 0.8mm account for 85%, and this material is used for PRB fill material for remediation of nitrate-contaminated groundwater.

[0025] It is determined that the porosity of the PRB filling material is 20%-24%, and the particle strength is about 30N.

[0026] Through the static test at room temperature in the laboratory, the rem...

Embodiment 2

[0028] Mix cement, fine sand and bentonite according to the mass ratio of 1:0.2-0.24:0.3-0.5 to prepare a stable and solidified adhesive, which is reserved for later use.

[0029] Take 1140g of reducing iron powder, 300g of stable curing adhesive, 240g of autotrophic denitrifying microbial bacterial agent with elemental iron as electron donor, 750g of zeolite and 300g of sand and mix them fully and evenly, and spray the remaining proportion of water to make the mixture moist. wet

[0030] Put the mixture into an extrusion spheronizer for granulation, and set the extrusion speed to 50r / min, and place it to dry under natural ventilation conditions. The particles with a particle size of 1cm account for 90%, and this material is used for restoration. PRB fill material for nitrate-contaminated groundwater.

[0031] It is determined that the porosity of the PRB filling material is 25%-28%, and the particle strength is about 30N.

[0032] Through the static test in the laboratory, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com