High-bonding-strength and waterproof ceramic tile bonding agent

A tile adhesive and adhesive technology, which is applied in the field of high bonding strength and waterproof tile adhesive, can solve the problems of easy-aging waterproof performance, hidden dangers, low bonding strength, etc., and meet the requirements of fixed strength, high Adhesive strength, the effect of high adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

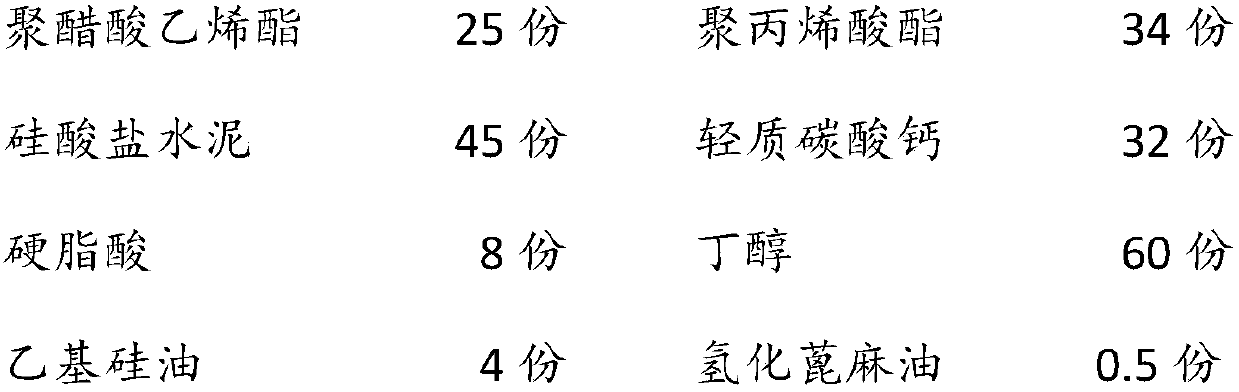

[0020] High bonding strength, waterproof tile adhesive, its raw material components include:

[0021]

[0022] Its preparation method is:

[0023] Accurately weigh the components of polyvinyl acetate, polyacrylate, Portland cement, light calcium carbonate, stearic acid, solvent, ethyl silicone oil and hydrogenated castor oil;

[0024] The Portland cement and the light calcium carbonate were placed in the dryer respectively, the control temperature was 80°C, and the drying time was 40min, for use;

[0025] Add polyvinyl acetate and polyacrylate to the solvent, control the stirring speed to be 90r / min, and the stirring time to be 30min to obtain the mixture a;

[0026] Add the dried Portland cement and light calcium carbonate into the mixture a, and stir at a stirring speed of 60 r / min for 2 min;

[0027] Add stearic acid and stir for 9min;

[0028] Add ethyl silicone oil, control the stirring speed to 120r / min, and stir for 10min;

[0029] The temperature was raised to 9...

Embodiment 2

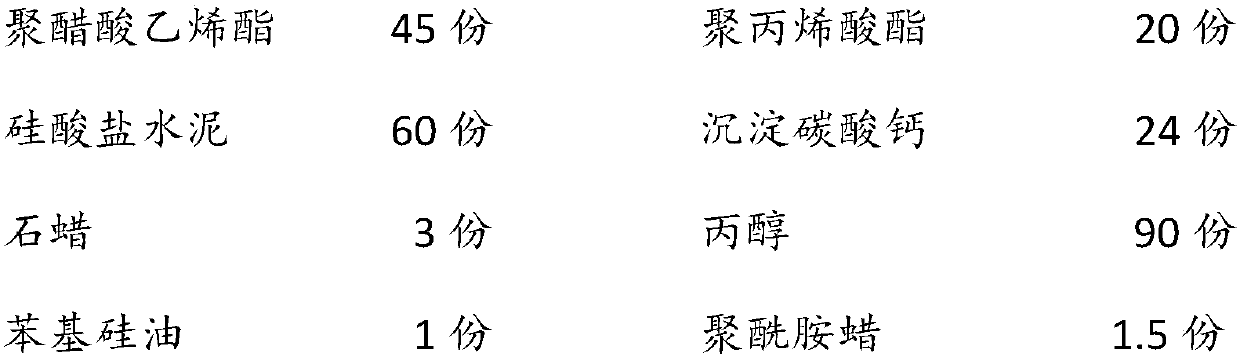

[0032] High bonding strength, waterproof tile adhesive, its raw material components include:

[0033]

[0034] Its preparation method is:

[0035] Accurately weigh the components of polyvinyl acetate, polyacrylate, Portland cement, precipitated calcium carbonate, paraffin, propanol, phenyl silicone oil and polyamide wax;

[0036] The Portland cement and the precipitated calcium carbonate were placed in the dryer respectively, the control temperature was 100°C, and the drying time was 30min, for use;

[0037] Add polyvinyl acetate and polyacrylate into propanol, control the stirring speed to be 50r / min, and the stirring time to be 15min to obtain mixture a;

[0038] Add the dried Portland cement and precipitated calcium carbonate to the mixture a, and stir at a stirring speed of 80 r / min for 4 min;

[0039] Add paraffin and stir for 6min;

[0040] Add phenyl silicone oil, control the stirring speed to be 180r / min, and stir for 18min;

[0041] The temperature is raised to...

Embodiment 3

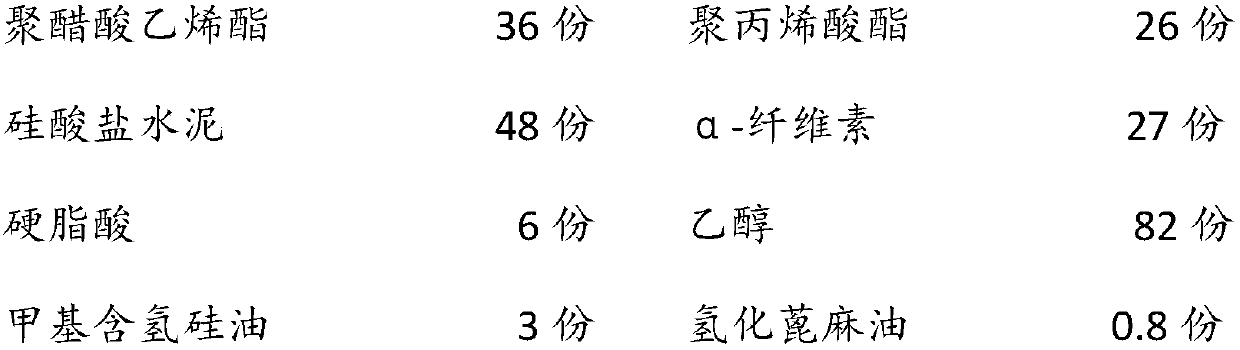

[0044] High bonding strength, waterproof tile adhesive, its raw material components include:

[0045]

[0046] Its preparation method is:

[0047] Accurately weigh the components of polyvinyl acetate, polyacrylate, Portland cement, α-cellulose, stearic acid, ethanol, methyl hydrogen silicone oil and hydrogenated castor oil;

[0048] The Portland cement and α-cellulose were placed in the dryer respectively, the control temperature was 94°C, and the drying time was 33min, for use;

[0049] Add polyvinyl acetate and polyacrylate into ethanol, control the stirring speed to be 76r / min, and the stirring time to be 25min to obtain mixture a;

[0050] Add the dried Portland cement and α-cellulose into the mixture a, and stir at a stirring speed of 76 r / min for 4 min;

[0051] Add stearic acid and stir for 8min;

[0052] Add methyl hydrogen-containing silicone oil, control the stirring speed to be 165r / min, and stir for 13min;

[0053] The temperature was raised to 68°C, hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com