Environment-friendly waterborne polyurethane adhesive used for plastic ground and preparation method thereof

A water-based polyurethane and adhesive technology, applied in the field of polyurethane applications, can solve problems such as water resistance, poor weather resistance, poor impact resistance, and poor stain resistance, and achieve good water resistance and weather resistance, high sports comfort, and environmental protection. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

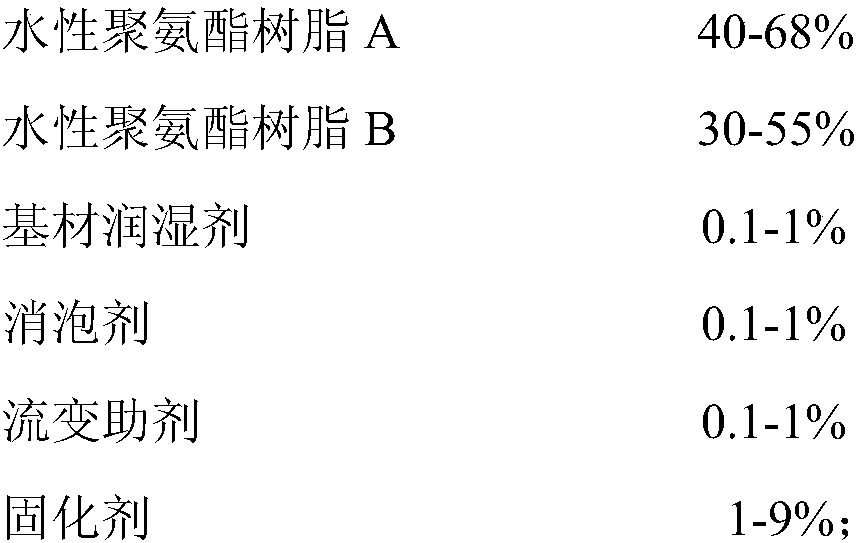

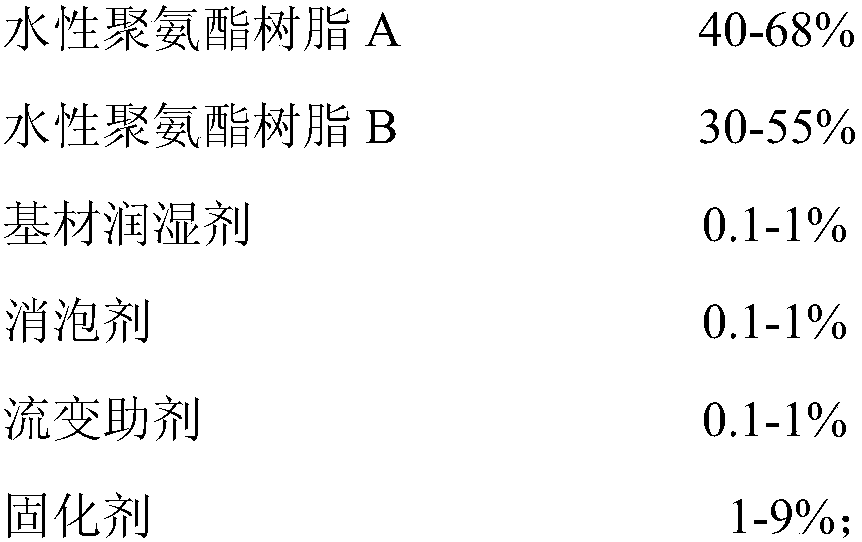

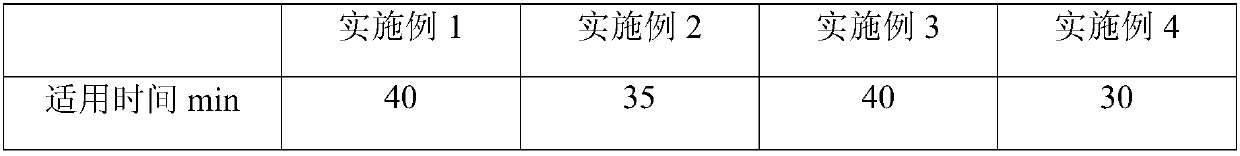

[0025] To prepare 1000g of one-component polyurethane adhesive, first combine 500g of water-based polyurethane resin Bayhydrol-UH-A (aliphatic anionic polyurethane water-based dispersion with a solid content of 30%-70%) and water-based polyurethane resin Bayhydrol-UH-B( Add 500g of aliphatic anionic polyurethane aqueous dispersion with a solid content of 20%-40%) to the reactor, stir at room temperature for 10 minutes; then add substrate wetting agent (EW-514, Daorun Chemical Technology (Shanghai) Co., Ltd.) 1g, antifoaming agent (Foamex N, Tego) 1g, rheology additive (WT-105A, Hainame Steqian) 1g, stir at room temperature for 10 minutes to obtain the first component, when using it, Add 1% curing agent (XP-2547, Bayer) to the mixture and stir thoroughly to obtain the environmentally friendly water-based polyurethane adhesive for plastic sites.

Embodiment 2

[0027] To prepare 1000g of one-component polyurethane adhesive, first combine 400g of water-based polyurethane resin Bayhydrol-XP-A (aliphatic anionic polyurethane water-based dispersion with a solid content of 30%-70%) with water-based polyurethane resin Bayhydrol-XP-B ( Add 600g of aliphatic anionic polyurethane aqueous dispersion with a solid content of 20%-40%) to the reaction kettle, stir at room temperature for 10 minutes; then add a substrate wetting agent (750, Wuhan Yuancheng Co-Creation Technology Co., Ltd.) ) 1g, defoamer (Foamex 815N, Tego) 1g, rheology additive (881-A, Qinghong) 1g, stir at room temperature for 10 minutes to obtain component A, when using, add 9% to component A The curing agent (XP-2655, Bayer) is fully stirred to obtain the environmentally friendly water-based polyurethane adhesive for plastic sites.

Embodiment 3

[0029] To prepare 1000g of one-component polyurethane adhesive, first mix 600g of waterborne polyurethane resin Dispercoll-A (aqueous dispersion of aliphatic anionic polyurethane with a solid content of 30%-70%) and waterborne polyurethane resin Dispercoll-B (solid content of 20%). %-40% aliphatic anionic polyurethane aqueous dispersion) 400g was added to the reaction kettle, stirred at room temperature for 10min; then sequentially added substrate wetting agent (750, Shenzhen Simequan Biotechnology Co., Ltd.) 1g, 1g foaming agent (Foamex 825N, Tego), 1g rheology additive (881-B, Qinghong), stir at room temperature for 10 minutes to obtain Part A, when using, add 5% curing agent (XP -2700, Bayer), fully stirred to obtain the environmentally friendly water-based polyurethane adhesive for plastic sites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com