Vertical-type bidirectional-heating low rank coal rapid pyrolysis device

A two-way heating and low-rank coal technology, which is applied in special forms of dry distillation, petroleum industry, coke oven, etc., can solve the problems of high content of heavy components, insufficient heating area, low tar yield, etc., and achieve good oil and gas quality, Increased heating area and high tar yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

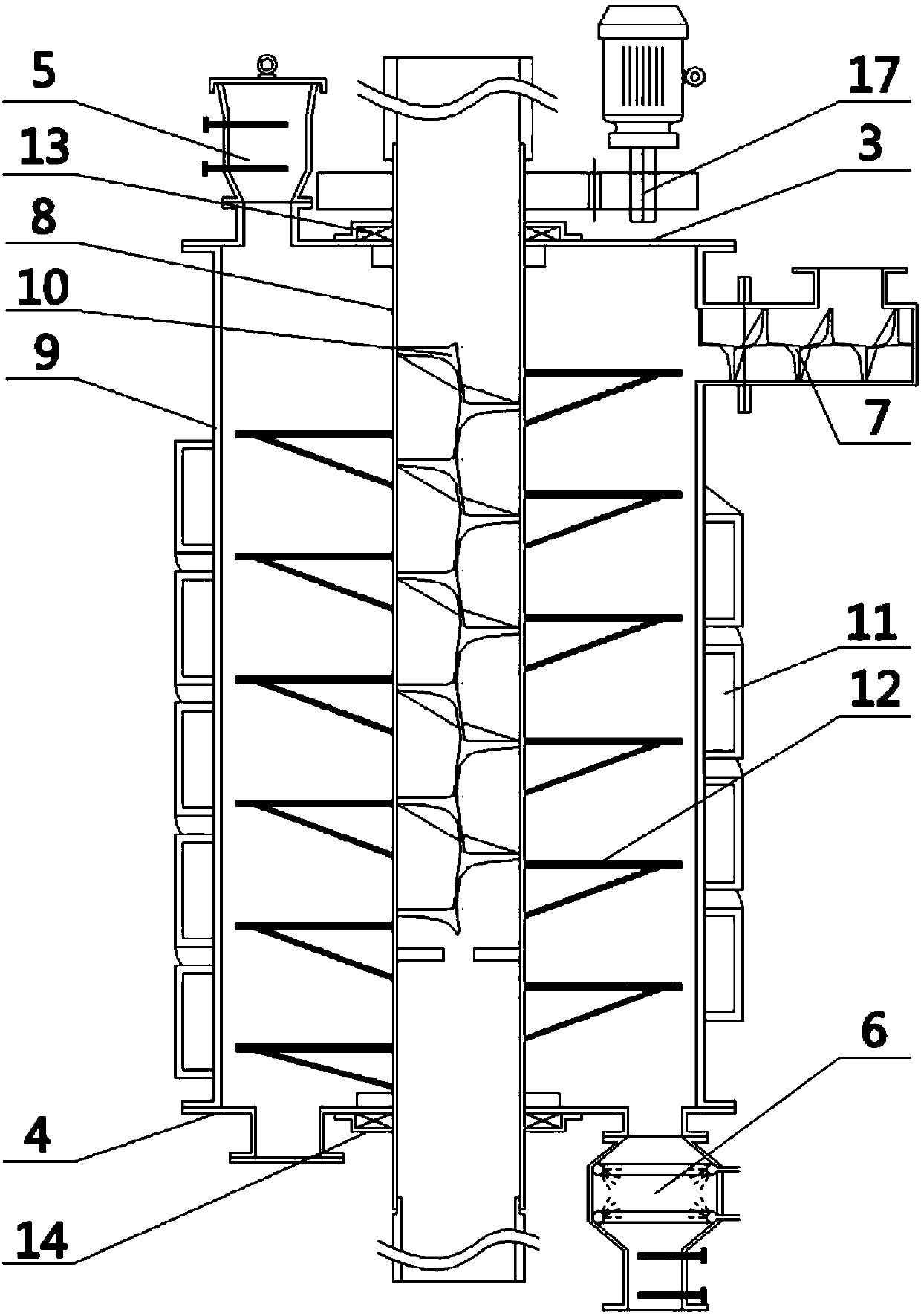

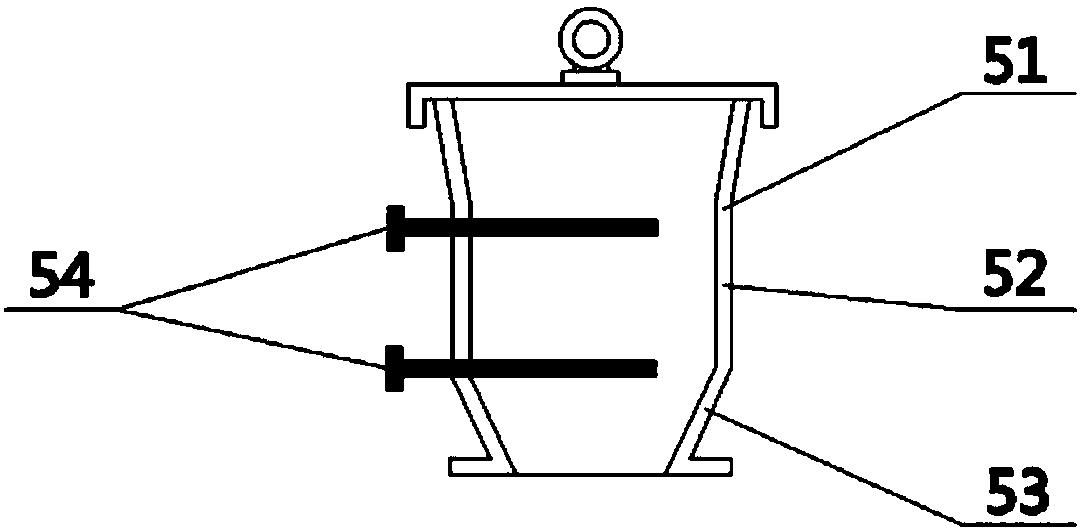

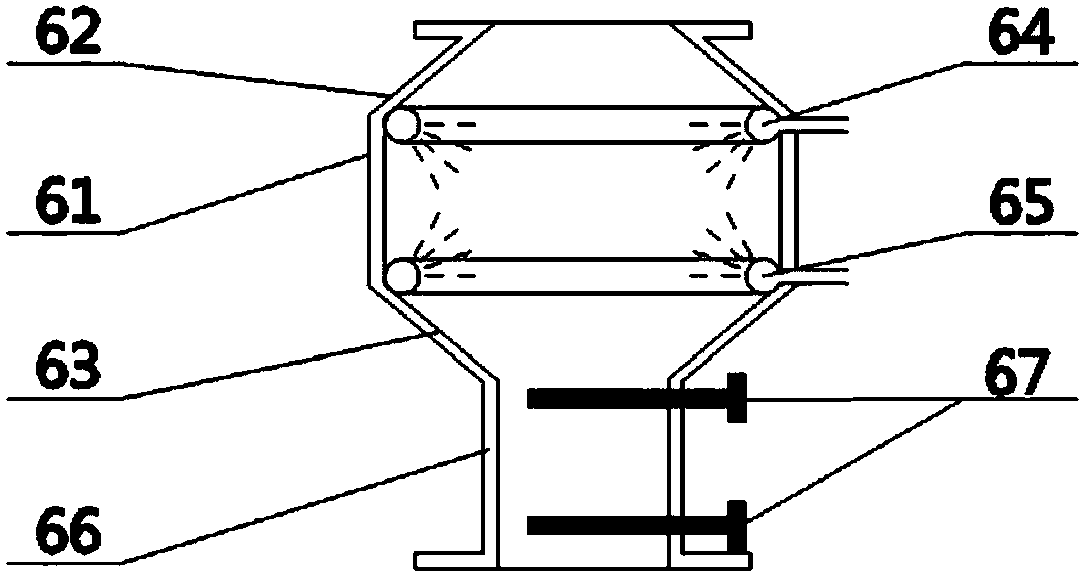

[0032] as attached figure 1 As shown in -7, the vertical two-way heating low-rank coal rapid pyrolysis device is characterized in that it includes an inner cylinder 1, an outer cylinder 2 covering the outer circumference of the inner cylinder 1, and connecting and fixing the inner cylinder 1 and the outer cylinder The upper end cover 3 and the lower end cover 4 of the 2 body, as well as the feeder 5, the cold feeder 6, the pyrolysis gas exporting device 7; the inner cylinder 8, the outer cylinder 9 and the upper and lower end covers (3, 4) The airtight space formed between constitutes the effective space of the pyrolysis device;

[0033] Wherein, the outer body cylinder 2 includes an outer cylinder 9, and the outer circumference of the outer cylinder 9 is spirally welded with a spiral coil 11 (the cross section is usually rectangular or circular), and a heating gas outlet and an inlet are left on the upper and lower sides of the spiral coil 11, thereby Form a heating gas spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com