Vertical type cooling device and application method thereof

A cooling device, vertical technology, applied in the direction of fluidized bed furnace, etc., to achieve the effect of strengthening heat exchange effect, improving yield and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

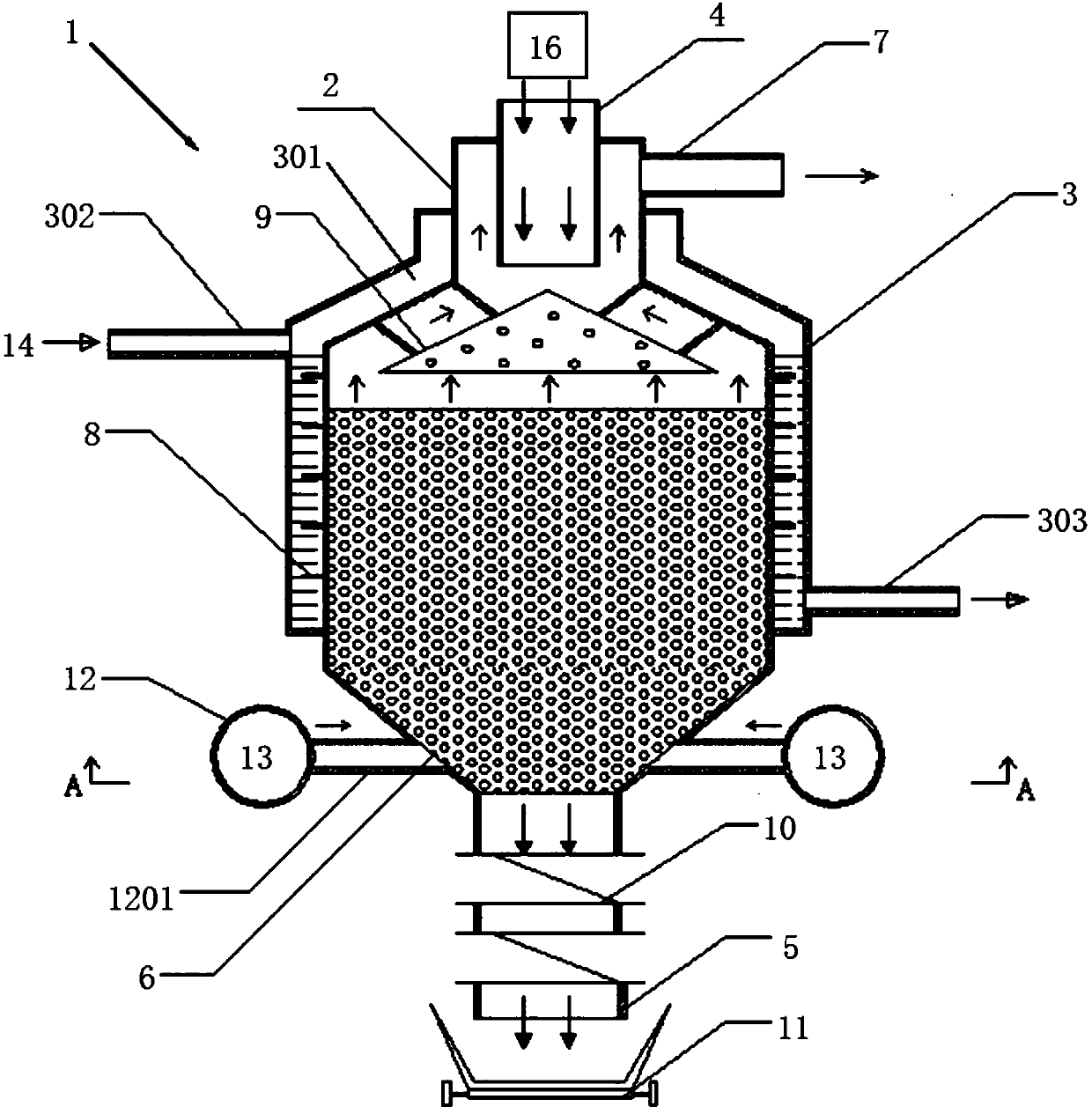

[0125] Such as figure 1 As shown, a vertical cooling device 1 includes a vertical cooling cylinder 2 . The top of the vertical cooling cylinder 2 is provided with a feeding port 4 . The bottom of the vertical cooling cylinder 2 is provided with a discharge port 5 . The periphery of the vertical cooling cylinder 2 is provided with a cooling jacket 3 . A space or gap 301 is provided between the cooling jacket 3 and the vertical cooling cylinder 2 . The cooling jacket 3 is a water cooling jacket. The upper part of the water cooling jacket is provided with an upper water inlet 302 of the water cooling jacket. The lower part of the water cooling jacket is provided with a water outlet 303 at the lower part of the water cooling jacket. Ribs 8 are provided in the voids or gaps 301 . The fins 8 are spiral fins. The fins 8 are arranged on the outer wall of the vertical cooling cylinder 2 . The outer diameter Φ of the vertical cooling cylinder is 8m. The height of the cylinder (...

Embodiment 2

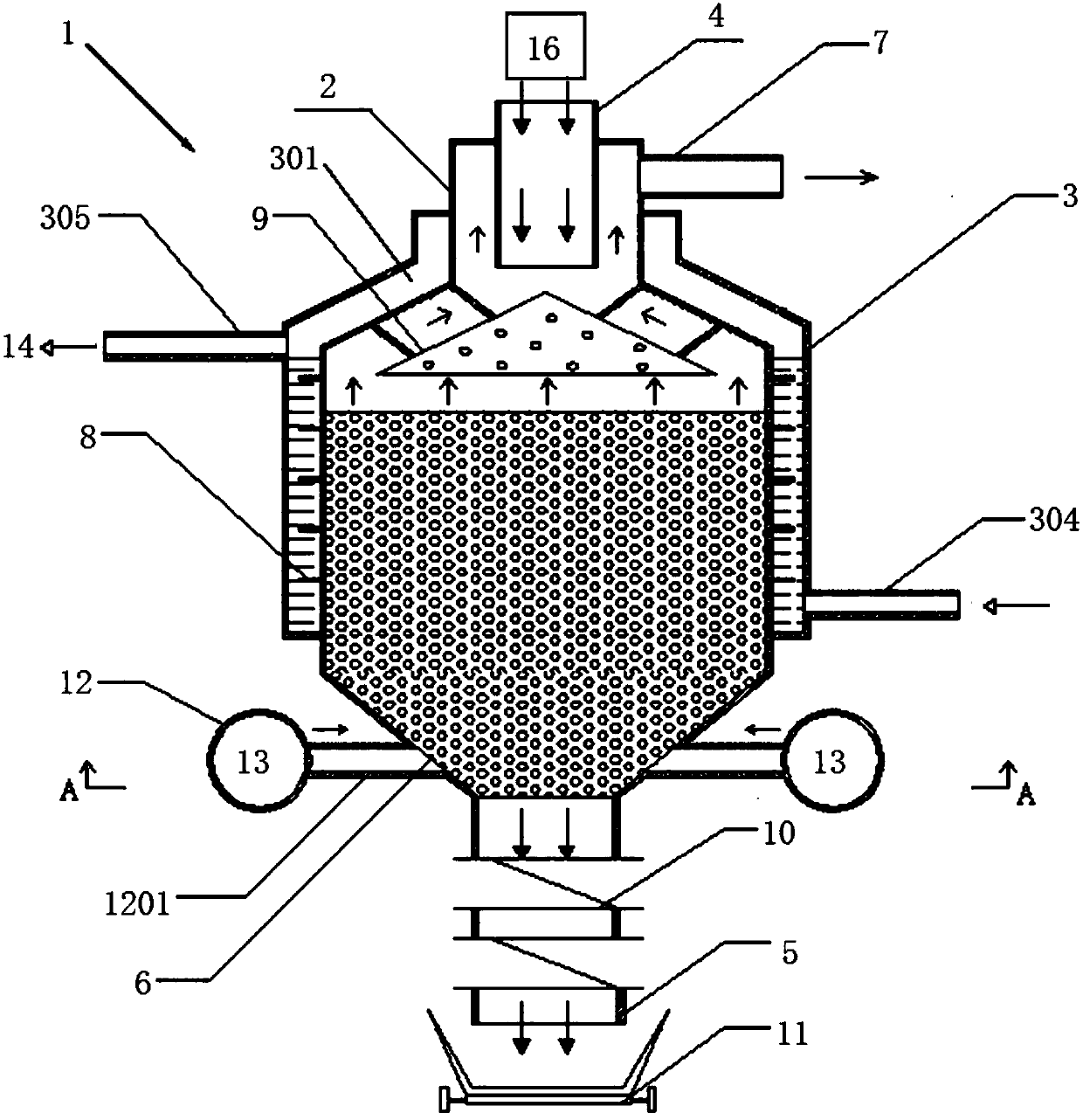

[0129] Such as figure 2 As shown, Example 1 is repeated, except that the cooling jacket 3 is another water-cooling jacket design, wherein the lower part of the water-cooling jacket is provided with a water inlet 304 at the lower part of the water-cooling jacket. The upper part of the water cooling jacket is provided with an upper water outlet of the water cooling jacket. The outer diameter Φ of the vertical cooling cylinder is 6m. The height of the cylinder (that is, the height difference from the inlet to the outlet) is 15m.

[0130] It takes 60-90 minutes to cool the direct reduced iron from 950°C-1000°C to 50°C by using the device.

Embodiment 3

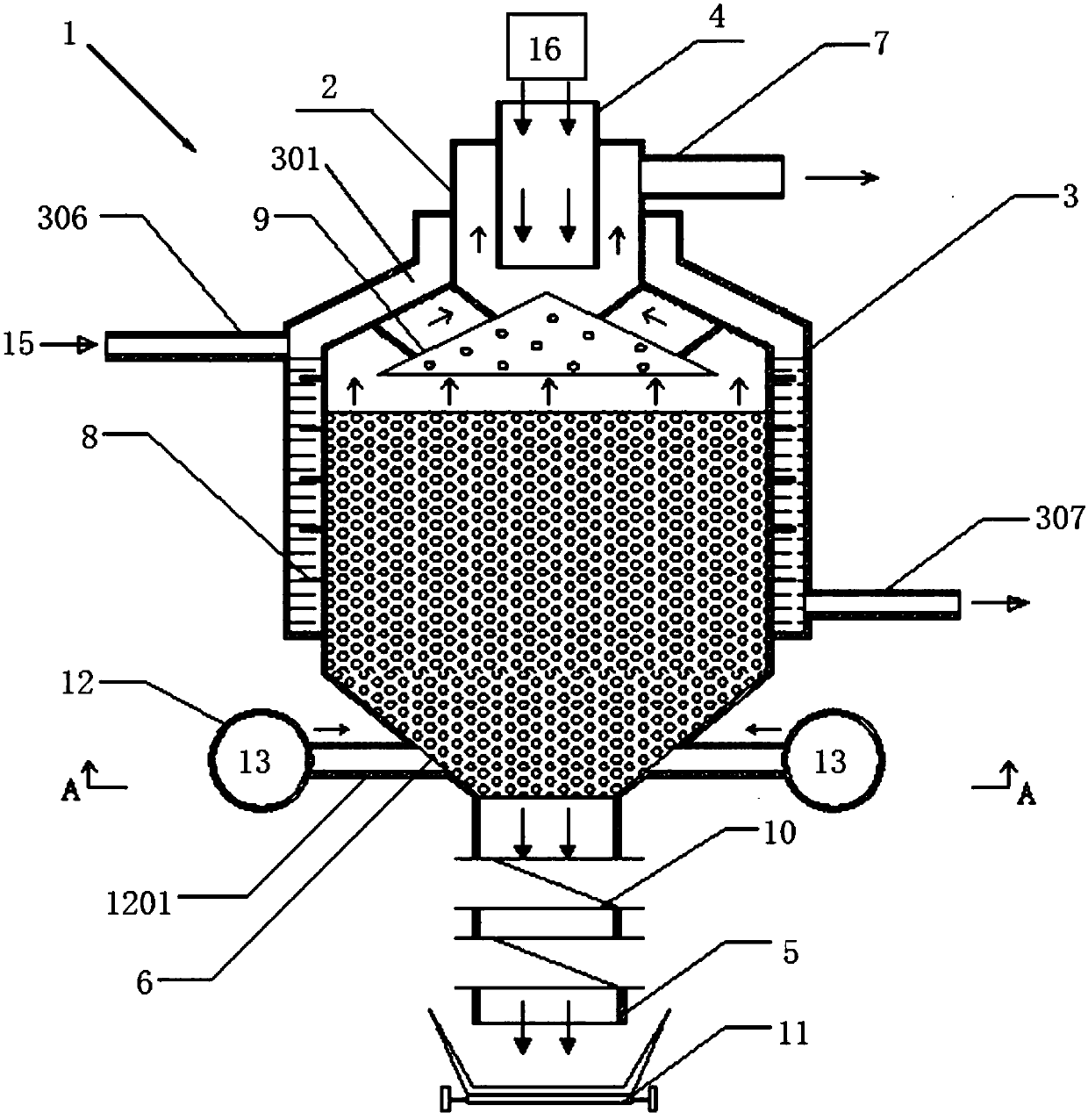

[0132] Such as image 3 Shown, repeat embodiment 1, only cooling jacket 3 is an air-cooled jacket. The upper part of the air-cooled jacket is provided with an upper air inlet 306 of the air-cooled jacket. The lower part of the air-cooled jacket is provided with an air outlet at the lower part of the air-cooled jacket. The outer diameter Φ of the vertical cooling cylinder is 7m. The height of the cylinder (that is, the height difference from the inlet to the outlet) is 16m.

[0133] It takes 90-110 minutes to cool the direct reduced iron from 950°C-1000°C to 50°C by using the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com