Cloth cutting mechanism

The technology of a cloth cutting mechanism and a conductive rod, which is applied to the cutting of textiles, papermaking, and textile materials, can solve the problems of complex structure, low work efficiency and high cost of the cutting machine, so as to reduce equipment costs and labor costs, and reduce cutting costs. The effect of fast speed and increased equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

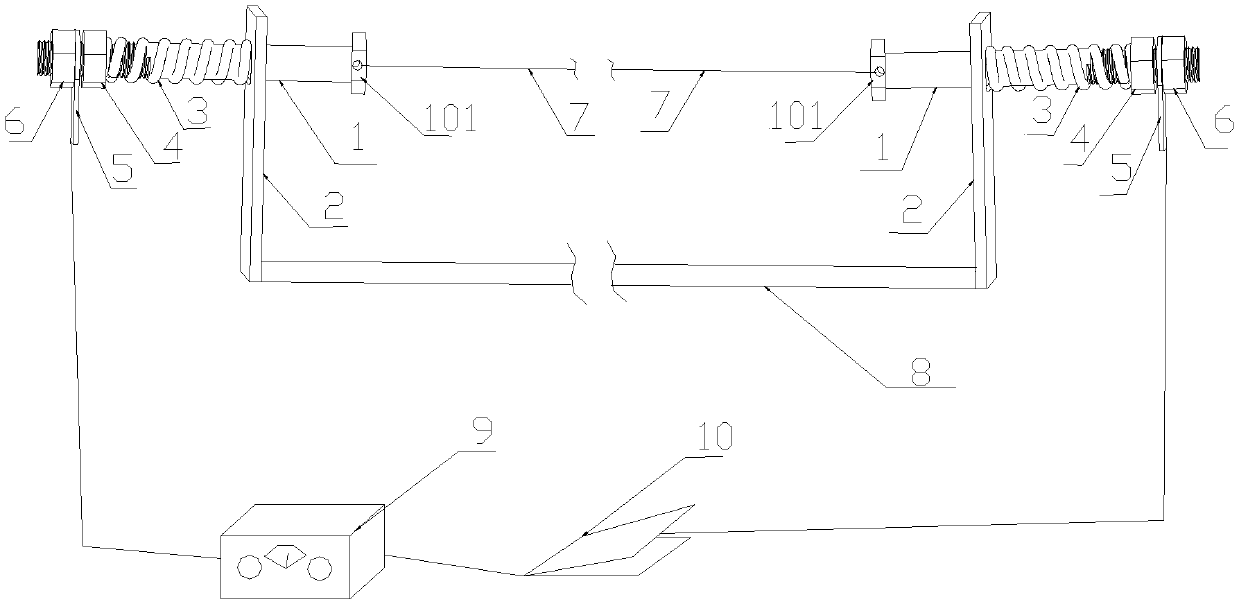

[0022] Such as figure 1 As shown, the present embodiment provides a kind of cloth cutting mechanism, and it comprises workbench 8, and workbench 8 is arranged horizontally, and the knife rest plate 2 that is vertically installed on the two ends of workbench 8, of course, knife rest plate 2 can be fixed by bolts , can also be tied to the workbench 8 or the table by welding or tying, the knife rest plate 2 is an insulating board, a wooden board or a plastic plate, the through hole provided on the top of the knife rest plate 2, the conductive rod 1 is a metal rod, and one end A cylindrical cap 101 with a diameter greater than the diameter of the through hole of the knife rest plate 2 is provided, and the other end of the conductive rod 1 is provided with a screw thread. The cylindrical cap of the conductive rod 1 is provided with a through hole connected with the heating wire 7, and the conductive rod 1 passes through. Through the through hole on the knife rest plate 2, the part ...

Embodiment 2

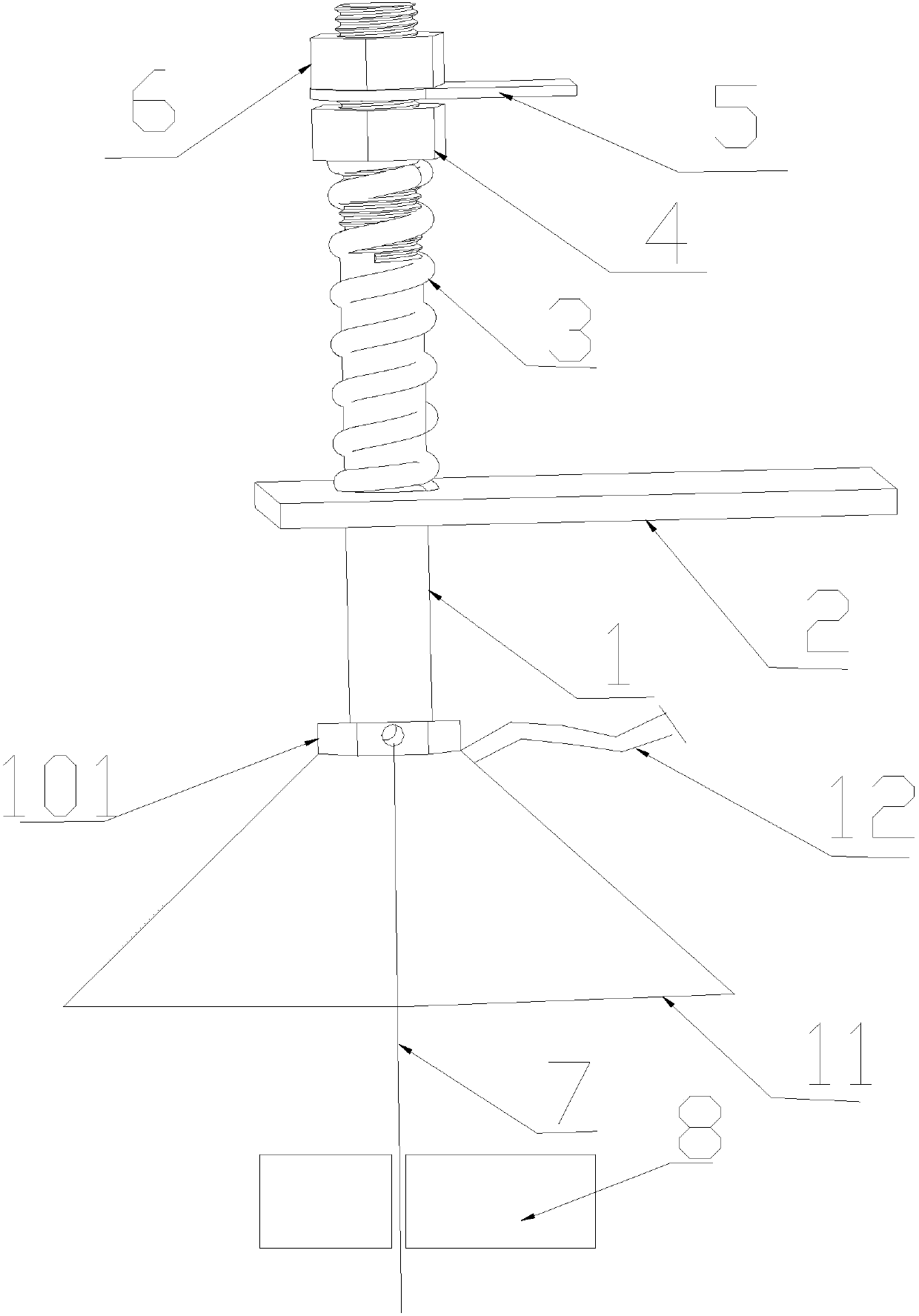

[0025] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the electric heating wire 7 is a molybdenum wire placed vertically, and the connection between the upper end of the electric heating wire 7 and the conductive rod 1 is provided with an exhaust hood 11, and the exhaust hood 11 is bolted to a conductive Rod 1 cylinder rises up, and exhaust hood 11 is connected with exhaust fan by exhaust pipe 12, and described exhaust hood 11 is made of transparent material. To cut the fabric, one end of the fabric is pulled up and passed through the heating wire 7 for thermal cutting. The gas generated during cutting can be extracted through the exhaust hood head 11 and the exhaust pipe 12. Adjusting the current can make the heating wire 7 produce different temperatures. In this way, fabrics of different thicknesses and materials can be cut, and the cutting speed is fast and there is no burr.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com