A kind of LED encapsulation structure and encapsulation method thereof with double-layer phosphor layer

A technology of LED encapsulation and phosphor layer, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven phosphor coating, decreased light output efficiency, and high processing cost, and achieve controllable light, heat reduction, packaging The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

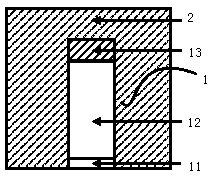

[0027] This embodiment has an LED packaging structure with double phosphor layers, such as figure 1 As shown, it includes a first package body 1 and a package adjustment phosphor layer 2 encapsulated on the top and side surfaces of the first package body; wherein, the first package body 1 includes LED chips 11 and substrate 12 arranged in sequence from bottom to top And phosphor layer 13.

Embodiment 2

[0029] Regarding the packaging method of the LED packaging structure with double phosphor layers of embodiment 1, the packaging method includes the following steps:

[0030] (1) First, perform WLP packaging, and coat a layer of phosphor on the back of the chip substrate after WLP packaging to form a phosphor layer 13 with a thickness of 10 µm-1000 µm;

[0031] (2) Cut the LED chip 11 coated with phosphor in step (1), and then use a splitting machine to split it from the dicing path until the split does not appear double crystals, forming the first package body 1;

[0032] (3) The first package 1 of step (2) is tested and binned, and the qualified first package 1 is sorted and arranged in accordance with the requirements of light and color separation according to brightness, display index and color temperature;

[0033] (4) Mix and stir the silica gel with a mass ratio of 97:3 and phosphor powder until no bubbles appear to form a regulated phosphor;

[0034] (5) Apply the first package b...

Embodiment 3

[0037] The packaging method of the LED packaging structure with double phosphor layers in this embodiment, wherein the LED chip 11 is a 820 chip, and the substrate 12 is a sapphire substrate. The specific packaging steps are as follows:

[0038] (1) First, perform WLP packaging, and coat a layer of phosphor on the back of the chip substrate after WLP packaging to form a phosphor layer 13 with a thickness of 100 µm;

[0039] (2) Cut the LED chip 11 coated with phosphor in step (1) to a size of 200 um×500 um, and then use a splitter to split from the dicing path until no double crystal appears in the split, forming the first package Body 1

[0040] (3) The first package body 1 in step (2) is tested and binned, and a single spot test is used, and the bins are divided according to different wavelength and brightness parameters. The qualified first package body 1 is based on the requirements of light and color separation. Sorting and arrangement of brightness, CRI and color temperature; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com