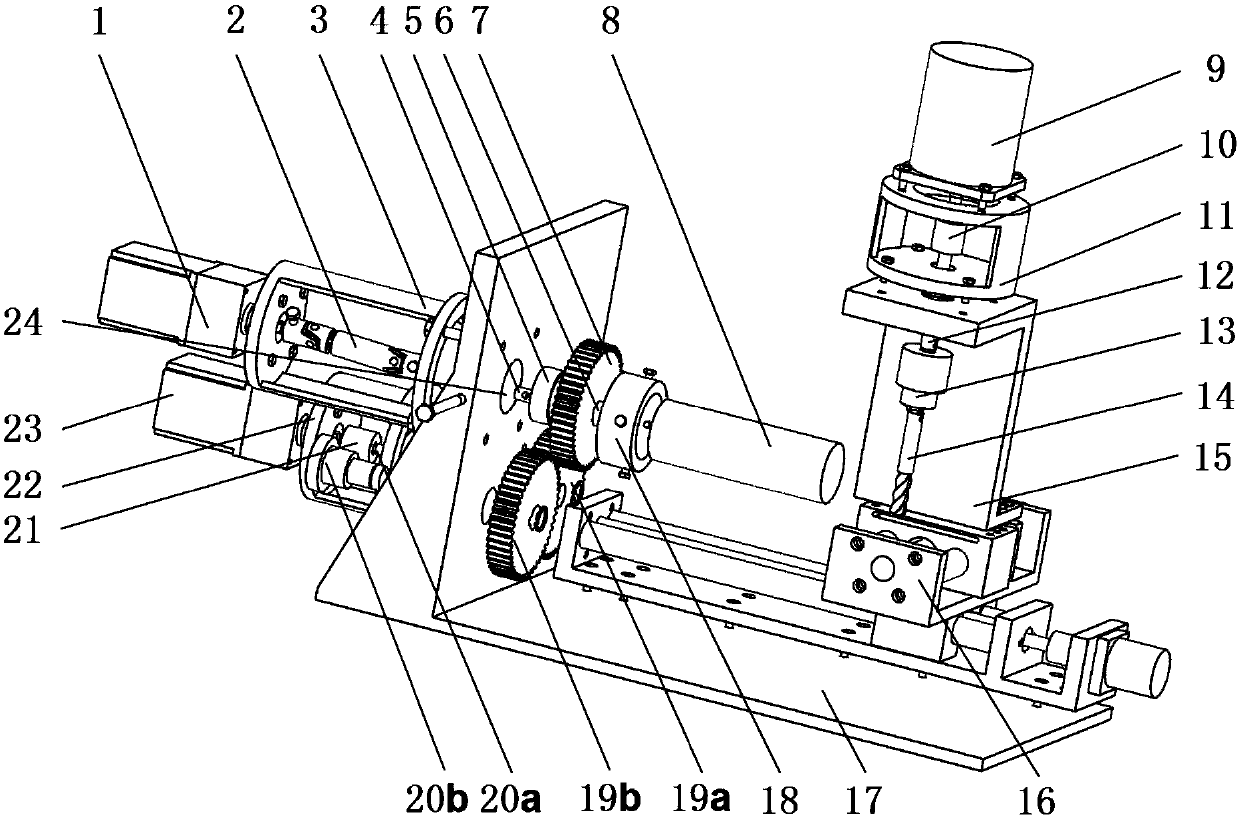

Method and device for turning-milling compound machining of rotor of oil extraction screw pump

A composite processing and screw pump technology, applied in the field of mechanical processing, can solve the problems of low production cost and short processing cycle, and achieve the effects of low production cost, short processing cycle and shortened processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

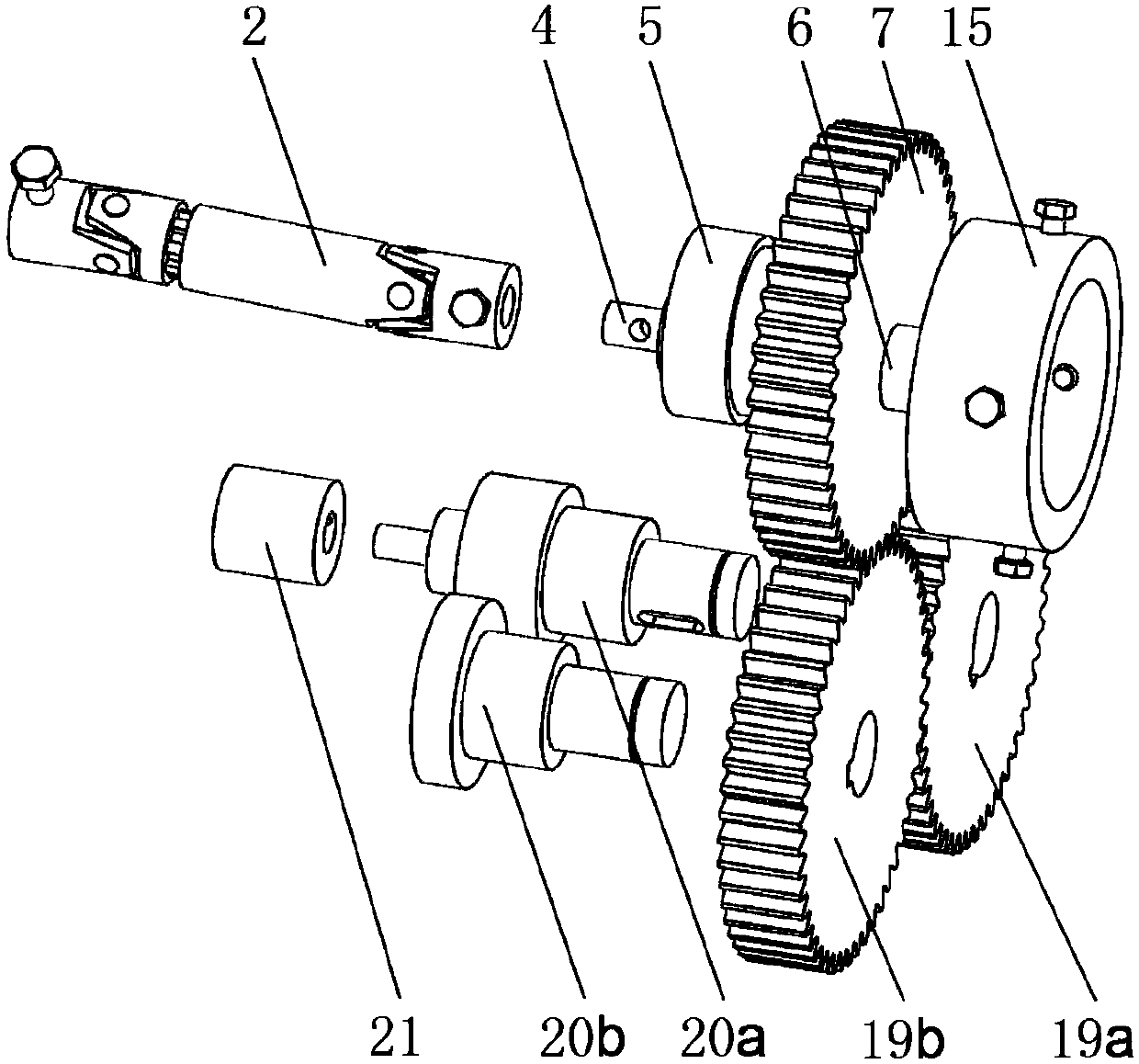

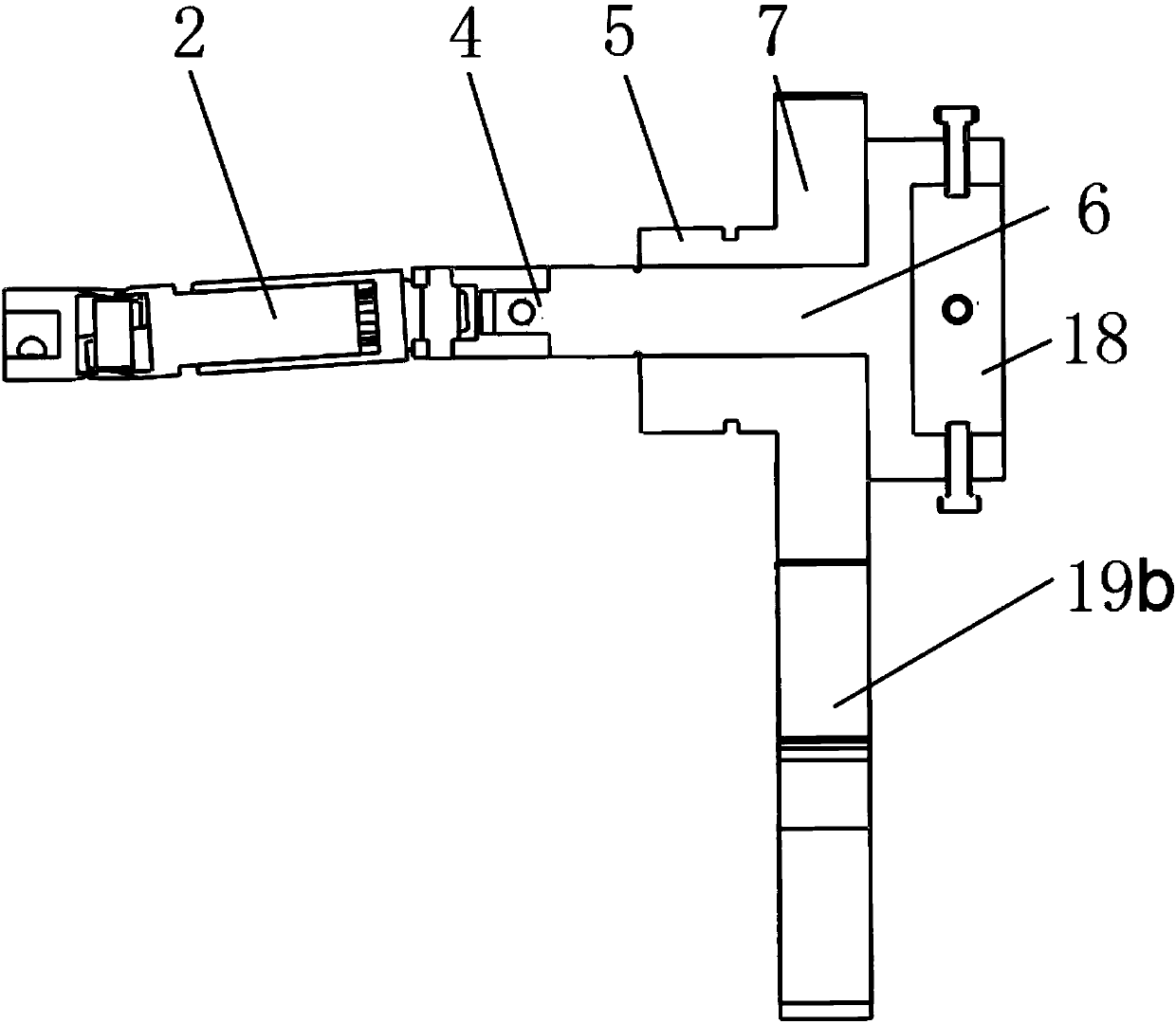

[0037] This embodiment is a rotor processing method, using the principle of relative motion of the three-headed short-width hypocycloid and the double-headed rotor, the three-headed short-width hypocycloid of the oil production screw pump is parallel to the length of the rotor when the amplitude coefficient is 0.5 A straight line of the coordinate axis of the shaft is used as an end mill, and the planetary movement of the rotor bar is realized by using the fixture, and the size of the rotor section and the section rotation position are controlled by the radial and axial movement of the end mill along the rotor bar To realize the processing of the rotor, the rotor bar with a diameter of 90mm is now processed into a double-head oil recovery screw pump rotor with a long axis and a short axis of 80mm and 50mm respectively, and a lead of 80mm.

[0038] It is known that the speed of stepper motor 1 is 120r / min,

[0039] The tool motor 9 rotates at 300r / min,

[0040] Each radial cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com