Anhydrous sodium sulfate production system and method by adopting two-effect mechanical thermal compression technology

A production system and thermal compression technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal sulfites/sulfites, etc. Drying efficiency, fast and uniform drying, the effect of accelerating production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

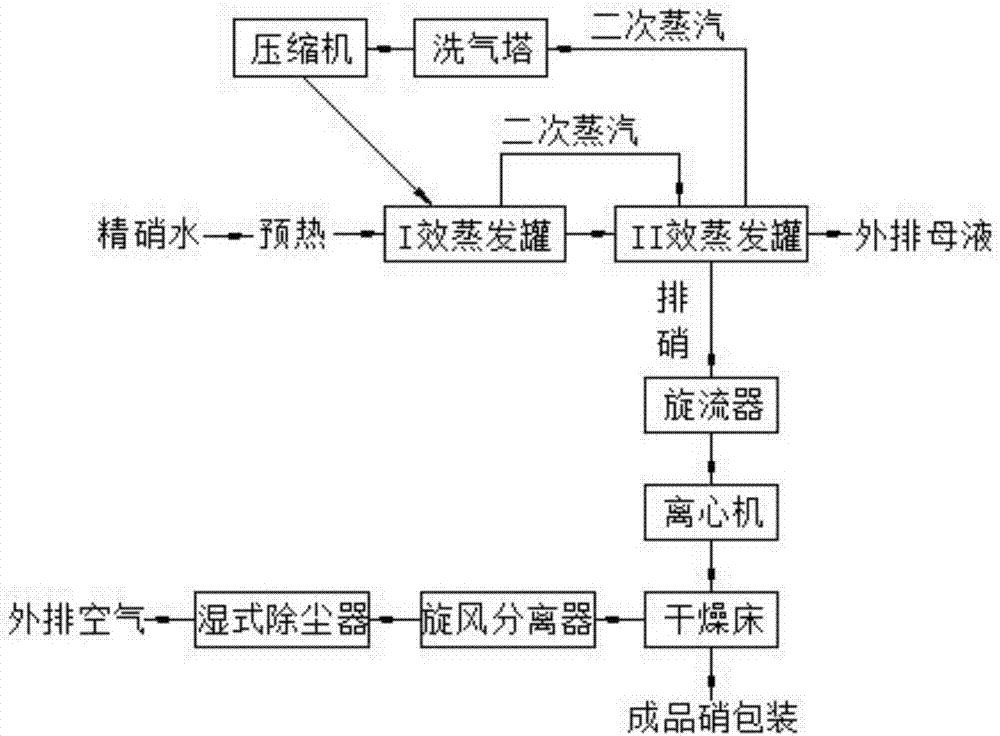

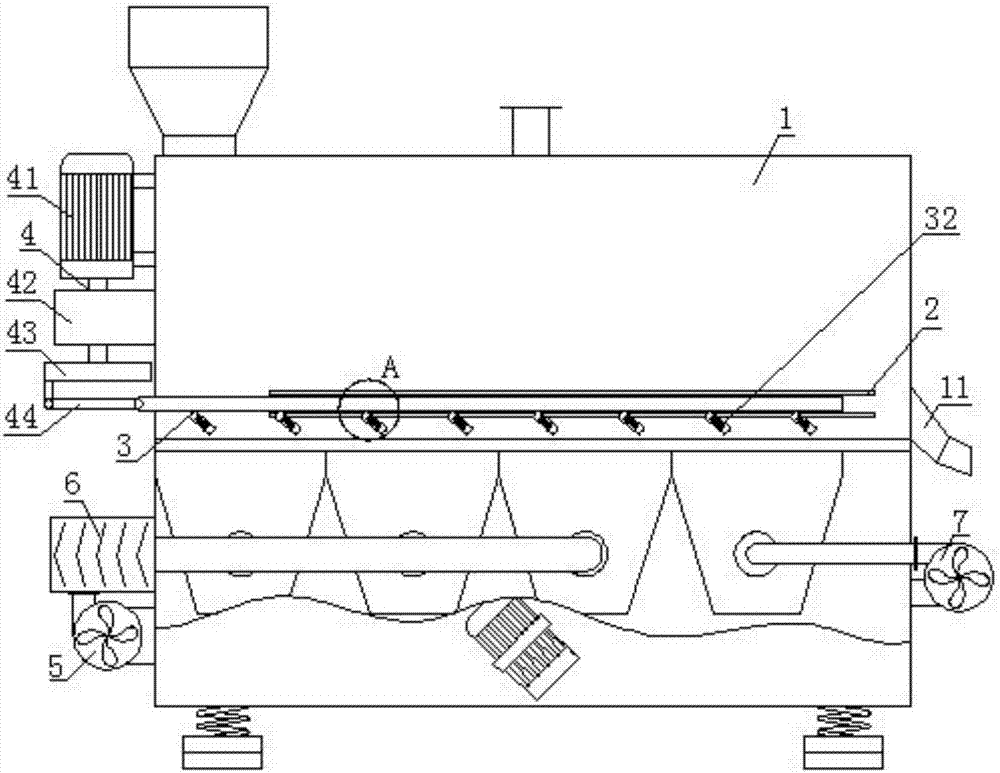

[0033] Such as figure 1 with figure 2 As shown, the present invention includes an evaporation system, the evaporation system is connected with a drying system for concentrating the nitrate slurry discharged from the evaporation system, and the drying system is connected with a purification system for purifying the drying system to discharge the nitrate-containing air; the drying system includes sequentially connected Cyclone, centrifuge, drying bed, the cyclone is connected to the evaporation system, and the drying bed is connected to the purification system; the drying bed includes a drying bed main body 1, and a drying chamber is arranged in the drying bed main body 1, and a chute is arranged in the drying chamber 2. A scraper mechanism 3 is set inside the chute 2, and a driving mechanism 4 for driving the scraper mechanism 3 to reciprocate is installed on the drying bed main body 1, and the driving mechanism 4 is connected to the scraper mechanism 3.

[0034] The inventio...

Embodiment 2

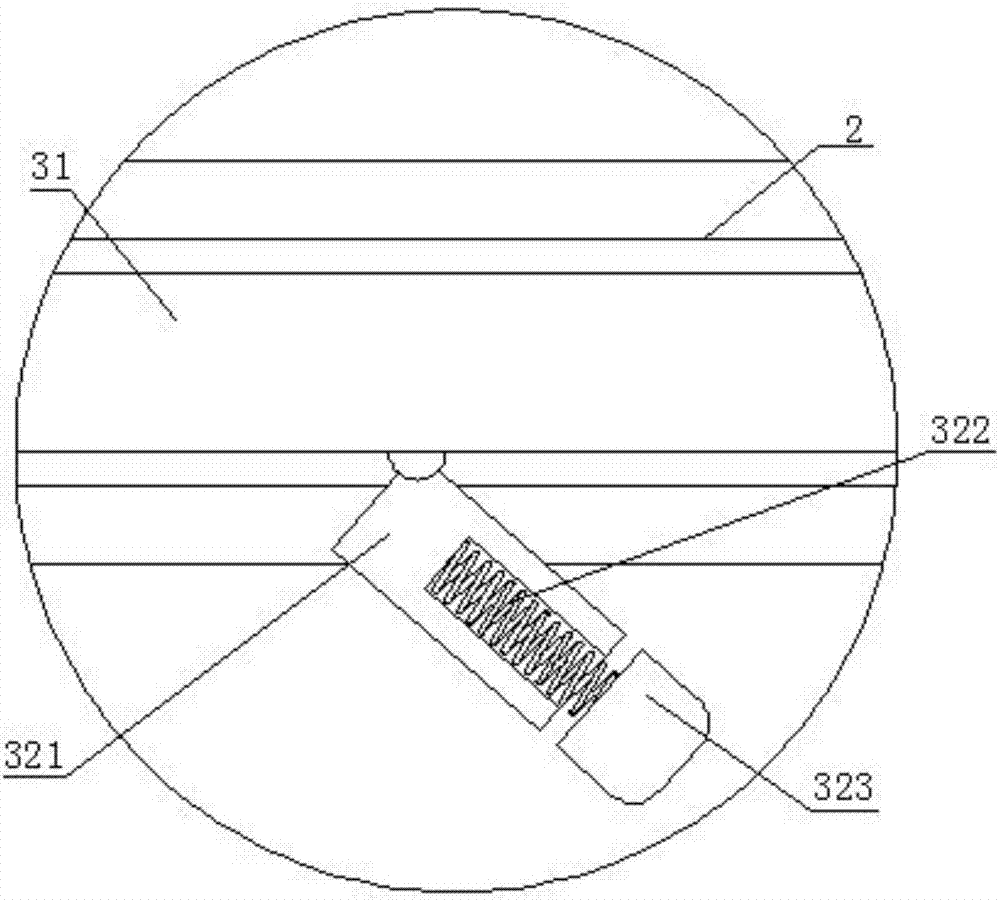

[0036] Such as image 3 As shown, on the basis of Embodiment 1, the scraper mechanism 3 includes a slide bar 31, the slide bar 31 is sleeved in the chute 2, and one end of the slide bar 31 is hinged to the drive mechanism 4; the scraper mechanism 3 also includes A plurality of mud scraping assemblies 32 , one side of the drying bed main body 1 is provided with a nitrate outlet 11 , and the upper end of the mud scraping assemblies 32 is hinged to the slide bar 31 at the side close to the nitration outlet 11 .

[0037] When the driving mechanism 4 pushes the sliding rod 31 to move towards the direction close to the nitric outlet 11, the mud scraping assembly 32 rotates to the vertical under the reaction force of the wet nitric acid, and the sliding rod 31 can stop the mud scraping assembly 32 from continuing to rotate, thereby scraping mud The assembly 32 can push the dried nitrate in the stratum of the drying chamber to move to the nitrate outlet 11, so as to ensure that the dr...

Embodiment 3

[0039] On the basis of Embodiment 1 or Embodiment 2, the mud scraping assembly 32 includes a rotating block 321, the side of the upper end of the rotating block 321 close to the nitrate outlet 11 is hinged with the slide bar 31, and the other end of the rotating block 321 is provided with Groove, the groove of the rotating block 321 is connected with a spring 322, and the other end of the spring 322 is connected with a scraper block 323.

[0040] The spring 322 on the rotating block 321 can push the mud scraping block 323 out, so that when the slide bar 31 moves close to the nitrate outlet 11, the mud scraping block 323 is always in contact with the bottom surface of the drying chamber to ensure that more dry nitrate is scraped The mud block 323 is scraped out, avoiding the accumulation of dry nitrate at the bottom of the drying chamber and being over-dried, and also avoiding the situation that the dry nitrate in the ground blocks the heating of the wet nitrate in the upper lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com