Lead-free low-melting-point tinted glass and preparation process thereof

A technology of colored glass and preparation process, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of exacerbating lead resource mining environment and human body harm, avoid pollution and bacterial reproduction, and improve chemical stability Sexuality and thermal stability, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

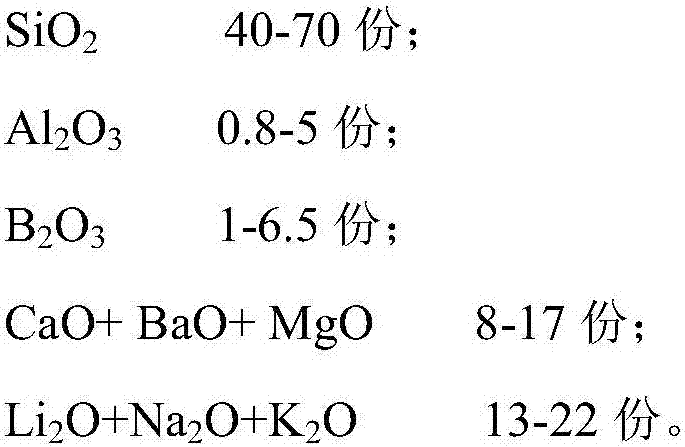

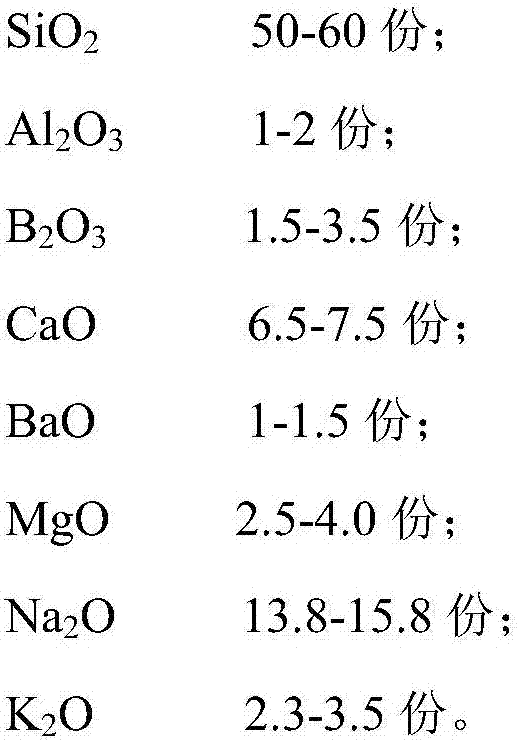

Method used

Image

Examples

Embodiment 1

[0029] A preparation process for lead-free low-melting colored glass, comprising the following steps:

[0030] 1) Ingredients: Weigh the raw materials according to the following composition proportions:

[0031] SiO 2 55g;Al 2 o 3 1.5g; B 2 o 3 2g; CaO 7g; BaO 1.2g; MgO 3g; 2 O 14g; K 2 O 3g; CuO 0.5g.

[0032] 2) Mixing: Put the weighed raw materials into a grinder for mixing and grinding until they are evenly mixed, then add 35mL hydrochloric acid aqueous solution to obtain a slurry; dry the slurry at 50°C to obtain a batch; wherein, the hydrochloric acid aqueous solution The mass concentration is 10%.

[0033] 3) Melting: Put the batch material into a platinum crucible, and then put the platinum crucible with the batch material into a resistance furnace for heating. The heating process is: from room temperature to 400°C, with a heating rate of 1.6°C / min , heat preservation for 1h; from 400°C to 700°C, the heating rate is 1.6°C / min, and heat preservation for 30mi...

Embodiment 2

[0038] A preparation process for lead-free low-melting colored glass, comprising the following steps:

[0039] 1) Ingredients: Weigh the raw materials according to the following composition proportions:

[0040] SiO 2 45g;Al 2 o 3 2g; B 2 o 3 3g; CaO 8g; BaO 2g; MgO 4g; 2 O 13g; K 2 O 5g; Co 2 o3 0.4g.

[0041] 2) Mixing: Put the weighed raw materials into a grinder for mixing and grinding until they are evenly mixed, then add 30mL hydrochloric acid aqueous solution to obtain a slurry; then dry the slurry at 40°C to obtain a batch; among them, hydrochloric acid The mass concentration of the aqueous solution is 10%.

[0042] 3) Melting: Put the batch material into a platinum crucible, and then put the platinum crucible with the batch material into a resistance furnace for heating. The heating process is: from room temperature to 400°C, with a heating rate of 1.6°C / min , heat preservation for 1h; from 400°C to 700°C, the heating rate is 1.6°C / min, and heat preservat...

Embodiment 3

[0047] A preparation process for lead-free low-melting colored glass, comprising the following steps:

[0048] 1) Ingredients: Weigh the raw materials according to the following composition proportions:

[0049] SiO 2 63g;Al 2 o 3 3g; B 2 o 3 4.5g; CaO 7g; BaO 4g; MgO 5g; 2 O 15g; K 2 O 4g; Co 2 o 3 0.4g.

[0050] 2) Mixing: Put the weighed raw materials into a grinder for mixing and grinding until they are evenly mixed, then add 40mL of hydrochloric acid aqueous solution to obtain a slurry; then dry the slurry at 40°C to obtain a batch; among them, hydrochloric acid The mass concentration of the aqueous solution is 10%.

[0051] 3) Melting: Put the batch material into a platinum crucible, and then put the platinum crucible with the batch material into a resistance furnace for heating. The heating process is: from room temperature to 400°C, with a heating rate of 1.7°C / min , keep warm for 1.5h; from 400°C to 700°C, the heating rate is 1.7°C / min, and keep warm for...

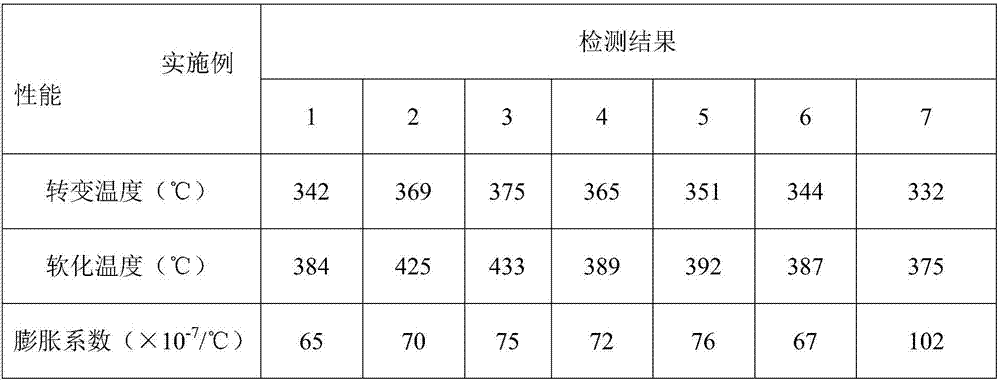

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transition temperature | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com