Soda residue light stabilized soil and preparation method thereof

A technology for solidifying soil and alkali slag, which is applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of affecting the environment and occupying land resources, and achieves the effect of wide application, wide applicability and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

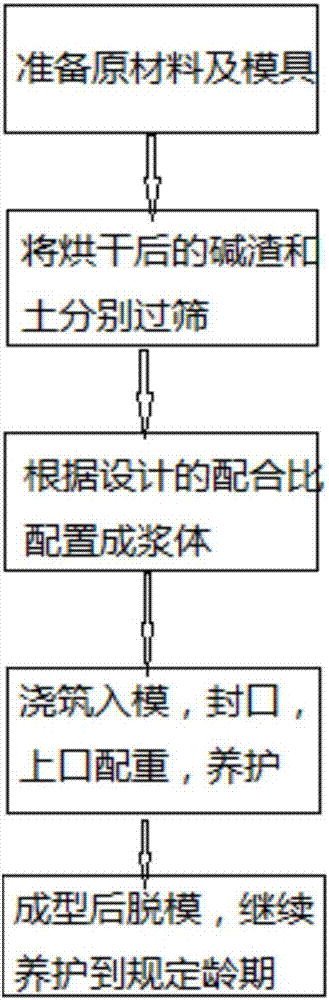

[0025] Another kind of specific embodiment of the present invention provides the preparation method of above any one solidified lightweight soil, comprises the following steps:

[0026] (1) Prepare raw materials, mould, stirring pot;

[0027] (2) Weigh dry soil, that is, alkali slag and soil, in a stirring pot, and the mass ratio of alkali slag and soil is 40:60-70:30. Based on dry soil, weigh 70-80% of water, 11-19% of cement, 4-10% of lime, 8-12% of fly ash, 0.3-0.7% of acrylamide, and 0.3% of the amount of acrylamide for ammonium persulfate. Aluminum powder 0.7-1.1%.

[0028] (3) Mix dry soil, cement, lime, fly ash and aluminum powder and stir evenly.

[0029] (4) Dissolve the acrylamide and ammonium persulfate weighed in step (2) in water first, then pour them into step (3) and stir thoroughly. This step is a critical step, the acrylamide gelatinous block in the mud must be stirred, otherwise the sample will crack after molding.

[0030] (5) Pour the fully stirred slur...

Embodiment 1

[0033] 1 Prepare the ingredients:

[0034] Weigh dry soil (alkali slag ratio soil 50:50),

[0035] In terms of dry soil weight, weigh 15% cement, 6% quicklime, 10% fly ash, 0.7% aluminum powder,

[0036] In terms of dry soil weight, weigh 80% water,

[0037] Based on dry soil weight, weigh 0.3% acrylamide, dissolve in water

[0038] Based on the weight of acrylamide, weigh 0.3% ammonium persulfate and dissolve it in water.

[0039] 2 Prepare the mold: the size is 46mm in inner diameter and 80mm in height. The inner wall is coated with petroleum jelly, and one end is wrapped with a breathable and impermeable membrane.

[0040] 3 Prepare the sample: Mix the weighed dry soil, cement, quicklime, fly ash, and aluminum powder, stir well, then pour in the acrylamide and ammonium persulfate dissolved in water, and stir well. Finally, the slurry is poured into the mold, and the delivery height is 60mm.

[0041] 4 Maintenance: Seal the mold and press the counterweight to maintain ...

Embodiment 2

[0043] Same as Example 1, the only difference lies in the content of dry soil and aluminum powder in the raw material: Weigh dry soil (alkali slag ratio soil 60:40), weigh 0.9% aluminum powder based on dry soil weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com