Production method of Buddha Jun porcelain handiwork

A production method and technology for handicrafts, applied in clay products, other household appliances, household appliances, etc., can solve the problems of low treasure rate, easy cracking, low Jun porcelain treasure rate, etc., achieve high yield, reduce melting temperature and high temperature Good effect of viscosity and glaze binding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

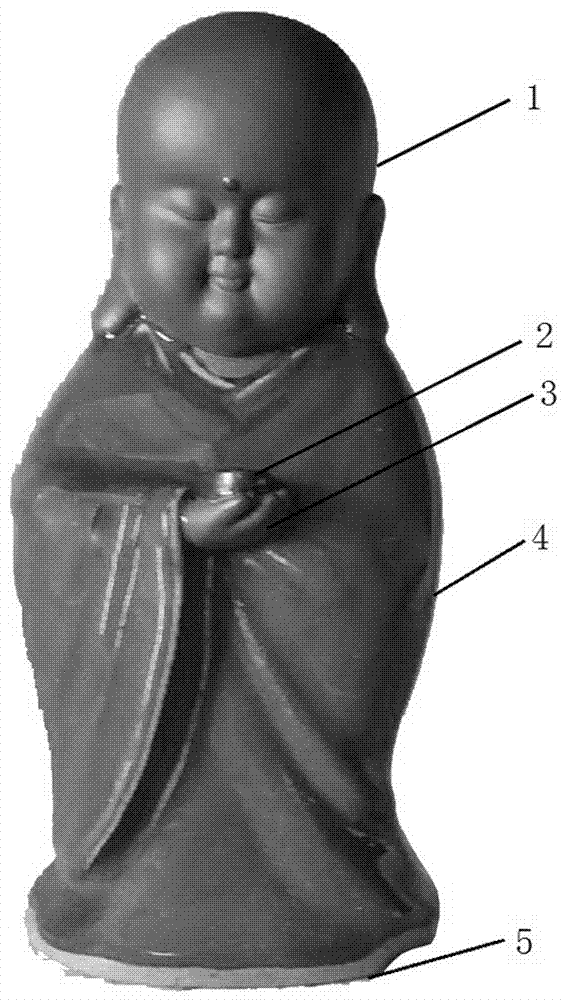

[0021] Such as figure 1 Shown, a kind of manufacture method of Fogong Jun porcelain handicraft, comprises the following steps:

[0022] Step 1. Carve the model; choose the general model carving method in this industry, divide the whole handicraft into multiple parts and carve them separately, including the head 1, the right hand part 2 and the main body 4. Among them, the palm of the right hand 2 is lifted up in front of the chest, the bowl 3 is placed in the palm, and the left hand is located in the hem of the main body 4 .

[0023] Step 2, making moulds; choosing the general method in this industry to make plaster molds for each part, and making plaster molds for the multiple parts carved in step 1.

[0024] Step 3, select pottery clay; said pottery clay includes the following components: 65% kaolin, 13% sandstone, 8% lead powder, 12% mullite, 1.5% iron ore, 0.2% cobalt oxide, and 0.3% edible alkali;

[0025] Step 4. Slurry: The pottery clay in step 3 is first roughly crus...

Embodiment 2

[0033] Such as figure 1 Shown, a kind of manufacture method of Fogong Jun porcelain handicraft, comprises the following steps:

[0034] Step 1. Carve the model; choose the general model carving method in this industry, divide the whole handicraft into multiple parts and carve them separately, including the head 1, the right hand part 2 and the main body 4. Among them, the palm of the right hand 2 is lifted up in front of the chest, the bowl 3 is placed in the palm, and the left hand is located in the hem of the main body 4 .

[0035] Step 2, making moulds; choosing the general method in this industry to make plaster molds for each part, and making plaster molds for the multiple parts carved in step 1.

[0036] Step 3. Select pottery clay; the pottery clay includes the following components: 70% kaolin, 10% sand, 8% lead powder, 10% mullite, 1.5% iron ore, 0.2% cobalt oxide, and 0.3% edible alkali.

[0037] Step 4. Slurry: The pottery clay in step 3 is first roughly crushed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com