Preparation method of 8-hydroxyquinoline

A hydroxyquinoline and quinoline technology, applied in the field of preparation of 8-hydroxyquinoline, can solve the problems of high temperature, high pressure and strong alkali usage, high requirements for safe production, and high production costs, and achieves the reduction of dosage and waste liquid. Emissions, the effect of reducing equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

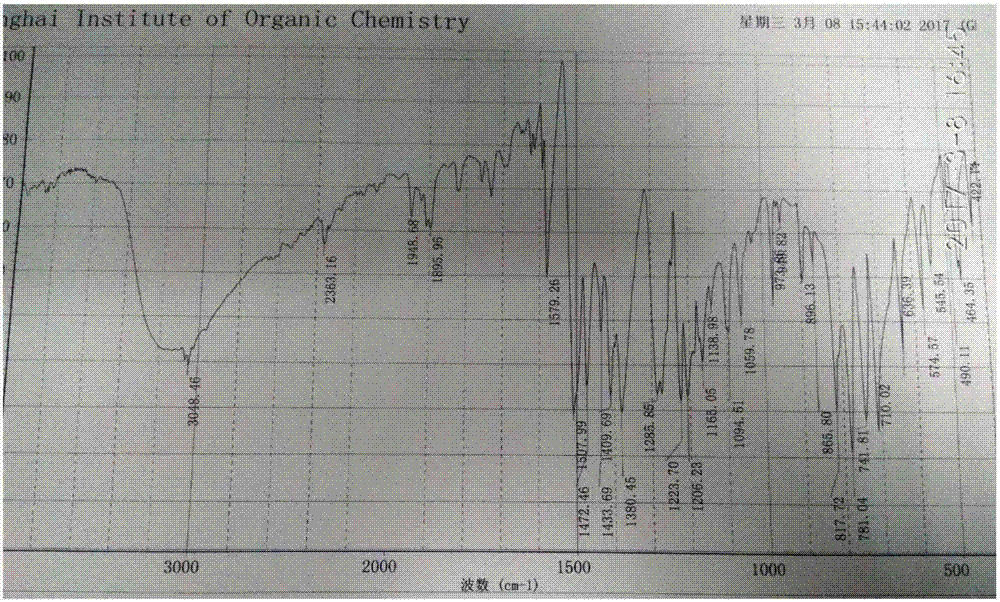

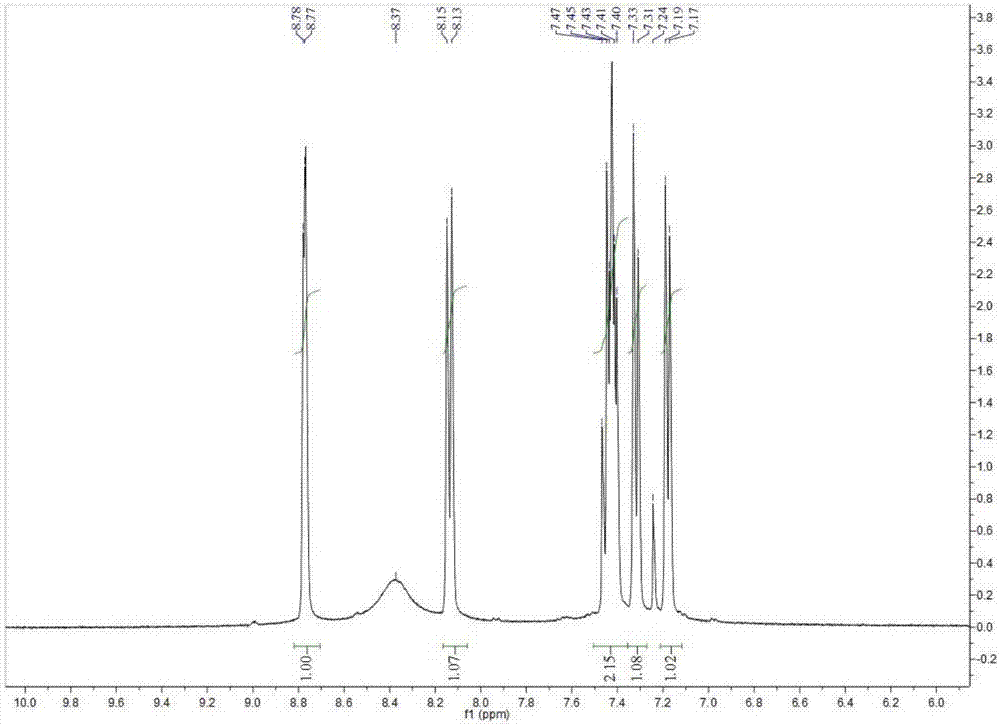

Image

Examples

Embodiment 1

[0043] First, put 250g of 65% fuming sulfuric acid into a 500ml three-necked flask, slowly add 100g of quinoline under stirring conditions, keep the temperature below 60℃, complete the addition within 3 hours, stir for another 30 minutes, slowly increase the temperature to After keeping at 120°C for 3 hours, cool to room temperature. The sulfonated liquid is slowly added to 400 g of ice water under stirring conditions, and after the dripping is completed, it is cooled to about 5° C., filtered, washed, and dried to obtain 140 g of 8-quinoline sulfonic acid.

[0044] Add 52g of 8-quinoline sulfonic acid obtained by the above method, 40g of water, 40g of sodium hydroxide and 5ml of catalyst methanol into the autoclave, seal and raise the temperature to 180℃, the pressure is 1.5MPa, carry out the alkali fusion reaction, and react for 7 hours Afterwards, the temperature was lowered to 60°C, the pressure was relieved, and 100ml of water was added to stir, then the reaction mixture was ...

Embodiment 2

[0046] First, put 300g of 65% fuming sulfuric acid into a 500ml three-necked flask. Under stirring conditions, slowly add 125g of quinoline, keep the temperature below 40℃, and complete the addition within 3 hours. After stirring for another 30 minutes, slowly heat up to After keeping at 115°C for 3 hours, cool to room temperature. The sulfonated liquid was slowly added to 425 g of ice water under stirring, and after the dripping was completed, it was cooled to about 5° C., filtered, washed, and dried to obtain 183 g of 8-quinoline sulfonic acid.

[0047] Add 52g of 8-quinoline sulfonic acid obtained by the above method, 60g of water, 57g of potassium hydroxide and 6ml of catalyst isopropanol into the autoclave, seal and raise the temperature to 170℃, the pressure is 1.4MPa, and carry out the alkali fusion reaction. After 7 hours, the temperature was lowered to 70°C, the pressure was relieved and 100ml of water was added to stir, then the reaction mixture was transferred to a 500...

Embodiment 3

[0049] First, put 300g of 65% fuming sulfuric acid into a 500ml three-necked flask. Under stirring conditions, slowly add 120g of quinoline, keep the temperature below 40℃, and complete the addition within 3 hours. After stirring for another 30 minutes, slowly increase the temperature to After holding at 110°C for 3 hours, cool to room temperature. The sulfonated liquid was slowly added to 425 g of ice water under stirring, and after the dripping was completed, it was cooled to about 5° C., filtered, washed, and dried to obtain 180 g of 8-quinoline sulfonic acid.

[0050] Add 52g of 8-quinoline sulfonic acid obtained by the above method, 50g of water, 40g of sodium hydroxide and 7ml of catalyst ethanol into the autoclave, seal and raise the temperature to 190℃, the pressure is 1.6MPa, carry out the alkali fusion reaction, and react for 8 hours Afterwards, the temperature was lowered to 70°C, the pressure was relieved, and 100ml of water was added to stir, then the reaction mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com