Environmental-friendly high-adhesion putty powder

A technology of high adhesion and putty powder, applied in the direction of filling slurry, etc., can solve the problems of water-resistant putty for wall scraping, low environmental index of putty powder, and poor adhesion, so as to improve wall adhesion and gloss Good, the effect of increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The environment-friendly high-adhesion putty powder of this embodiment is made of the following raw material components in parts by weight: 320 parts of gypsum, 25 parts of pregelatinized starch, 10 parts of starch mud, 6 parts of carboxymethyl cellulose, hydroxypropyl 10 parts of methyl cellulose, 8 parts of sodium lauryl sulfate, 3 parts of hydroxyethyl cellulose, 6 parts of organic polymer, 18 parts of bentonite, 15 parts of superfine powder of heavy calcium carbonate powder; wherein, by weight Percentage, the organic polymer includes polyvinyl alcohol 35%, polyacrylamide 20%, silicone emulsion 20%, silicone modified acrylic resin 25%.

Embodiment 2

[0017] The environment-friendly high-adhesion putty powder of this embodiment is made of the following raw material components in parts by weight: 280 parts of gypsum, 30 parts of pregelatinized starch, 12 parts of starch mud, 8 parts of carboxymethyl cellulose, hydroxypropyl 12 parts of methyl cellulose, 6 parts of sodium lauryl sulfate, 3 parts of hydroxyethyl cellulose, 8 parts of organic polymer, 15 parts of bentonite, 18 parts of superfine powder of heavy calcium carbonate powder; wherein, by weight Percentage, the organic polymer includes polyvinyl alcohol 40%, polyacrylamide 25%, silicone emulsion 15%, silicone modified acrylic resin 20%.

Embodiment 3

[0019] The environment-friendly high-adhesion putty powder of this embodiment is made of the following raw material components in parts by weight: 350 parts of gypsum, 22 parts of pregelatinized starch, 15 parts of starch mud, 5 parts of carboxymethyl cellulose, hydroxypropyl 15 parts of methyl cellulose, 6 parts of sodium lauryl sulfate, 4 parts of hydroxyethyl cellulose, 7 parts of organic polymer, 12 parts of bentonite, 16 parts of superfine powder of heavy calcium carbonate powder; Percentage, the organic polymer includes polyvinyl alcohol 40%, polyacrylamide 15%, silicone emulsion 15%, silicone modified acrylic resin 30%.

[0020] Wherein, the fineness of above-mentioned ground calcium carbonate powder superfine powder is 800 orders.

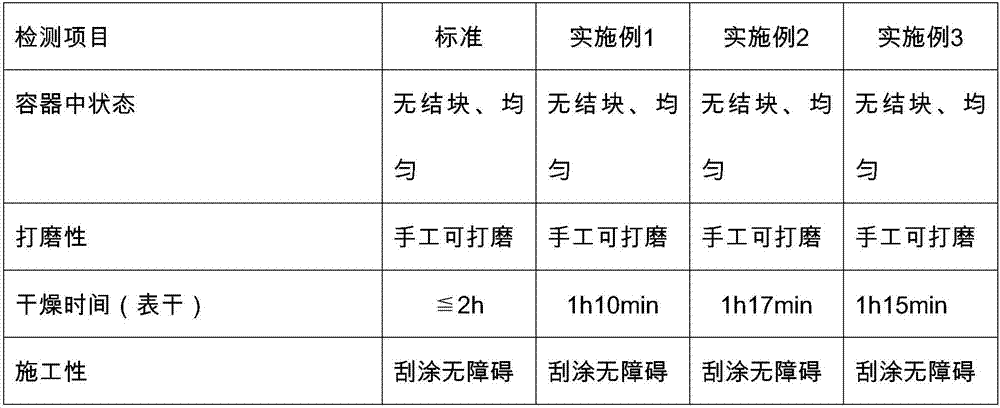

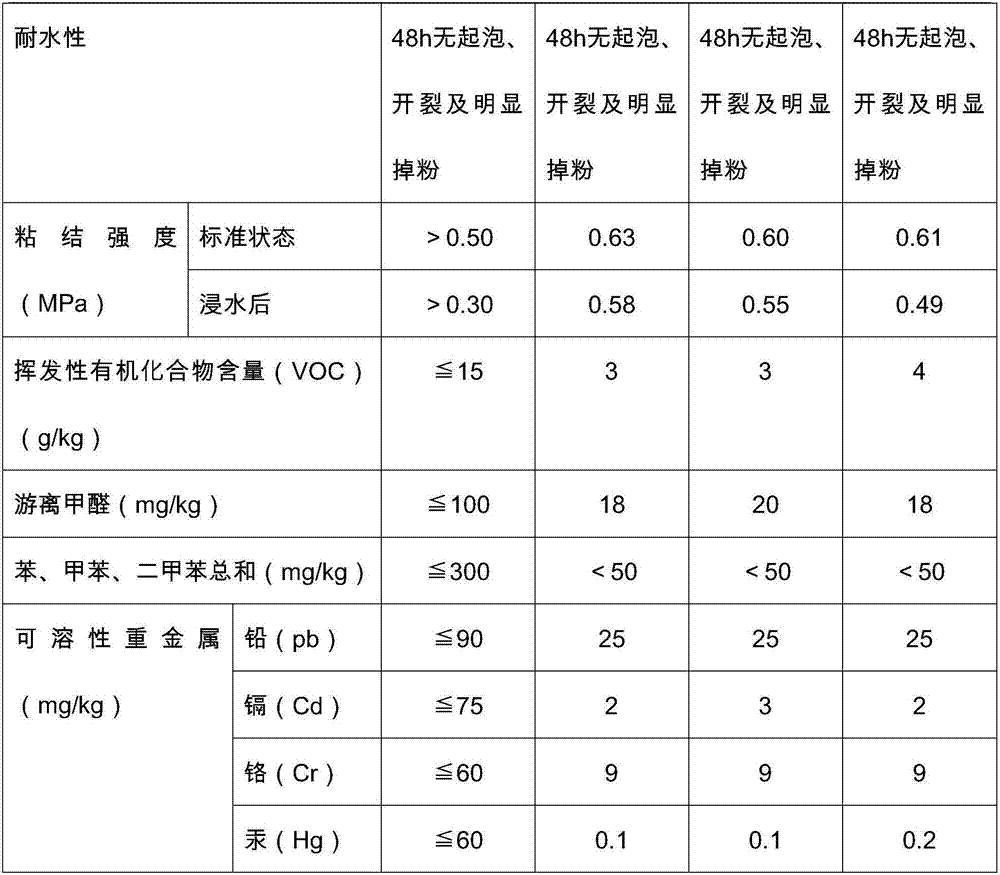

[0021] The quality inspection data of the environment-friendly type high adhesion putty powder of present embodiment 1-3 are as shown in table 1 below:

[0022] Table 1 present embodiment 1-3 quality detection data table

[0023]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com