Processing method for improving corrosion resistance of Mg-Y-Nd based alloy

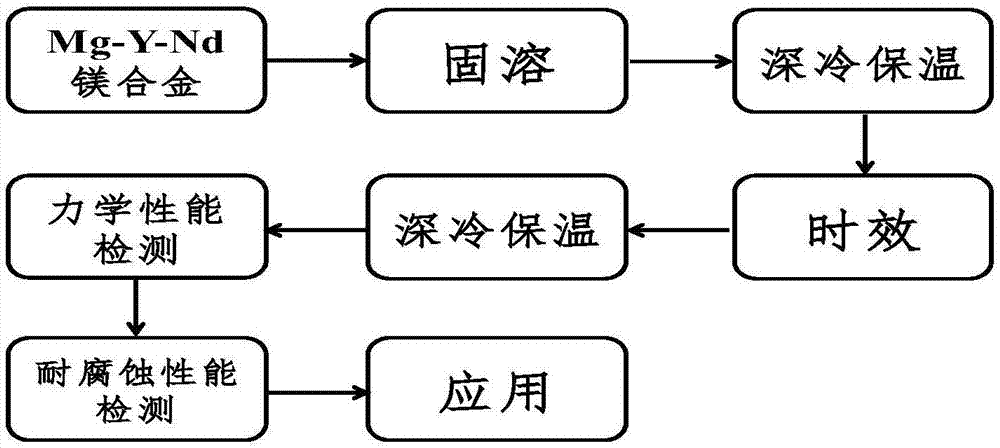

A treatment method and a technology of base alloys, which are applied in the field of treatment to improve the corrosion resistance of Mg-Y-Nd base alloys, can solve problems such as cumbersome process flow, and achieve strong operability, simple and easy-to-master methods, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]The preparation of Mg-Y-Nd alloy is according to the conventional preparation method, and industrial pure magnesium, industrial pure neodymium, industrial pure yttrium are smelted as raw materials; the sample is cut from the smelted magnesium alloy ingot. Select a representative part of the ingot to cut a magnesium alloy test piece with a size of 50×50×5mm for the corrosion weight loss rate test; cut a magnesium alloy test piece with a size of 10×10×10mm for the electrochemical corrosion performance test; According to the national standard GB / T 228.1-2010, the tensile specimens with mechanical properties at room temperature are cut and processed to meet the standards. The mass percent composition of the components in the obtained Mg-Y-Nd alloy: 7.11wt.% Y, 1.52wt.% Nd, impurity elements Al<0.01wt.%, Fe<0.01wt.%, Cu<0.01wt.%, Ni <0.01wt.%, the rest is Mg. The alloy was rolled at 450°C.

[0038] Cryogenic treatment and conventional treatment of the above obtained Mg-Y-Nd...

Embodiment 2

[0050] Cast Mg-5Y-1Nd

[0051] The as-cast Mg-5Y-1Nd alloy is prepared in a conventional way, and then the as-cast Mg-5Y-1Nd alloy is solid solution treated at a solution temperature of 515°C and kept for 16 hours; after solid solution, the alloy is immediately taken out and placed in liquid nitrogen Quenching in the environment, keeping deep cooling for 8h; then, heating to 200°C for aging treatment, the aging time is 12h; after aging, immediately take out the alloy and place it in a liquid nitrogen environment for quenching, keeping deep cooling for 6h (see Figure 6 ).

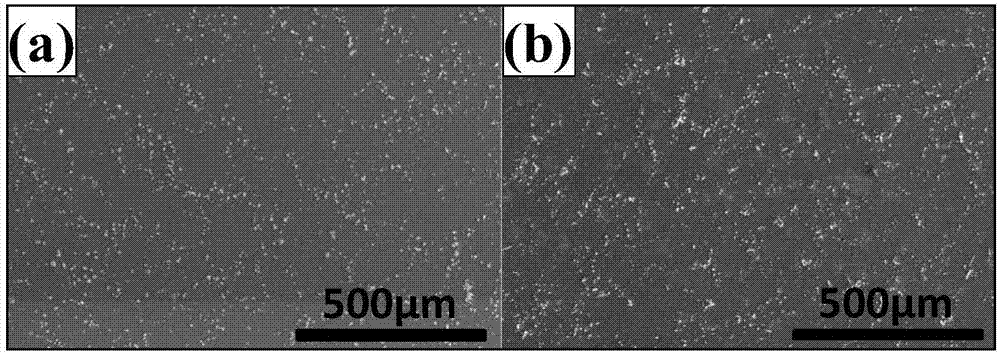

[0052] Depend on Figure 6 Visible, wherein (a) is cryogenic treatment Mg-5Y-1Nd alloy microstructural structure, (b) is routine processing Mg-5Y-1Nd alloy microstructural structure, can be seen through the alloy after cryogenic treatment of the present invention by two alloy microstructural structures The structure is better, and the precipitated phase is evenly distributed.

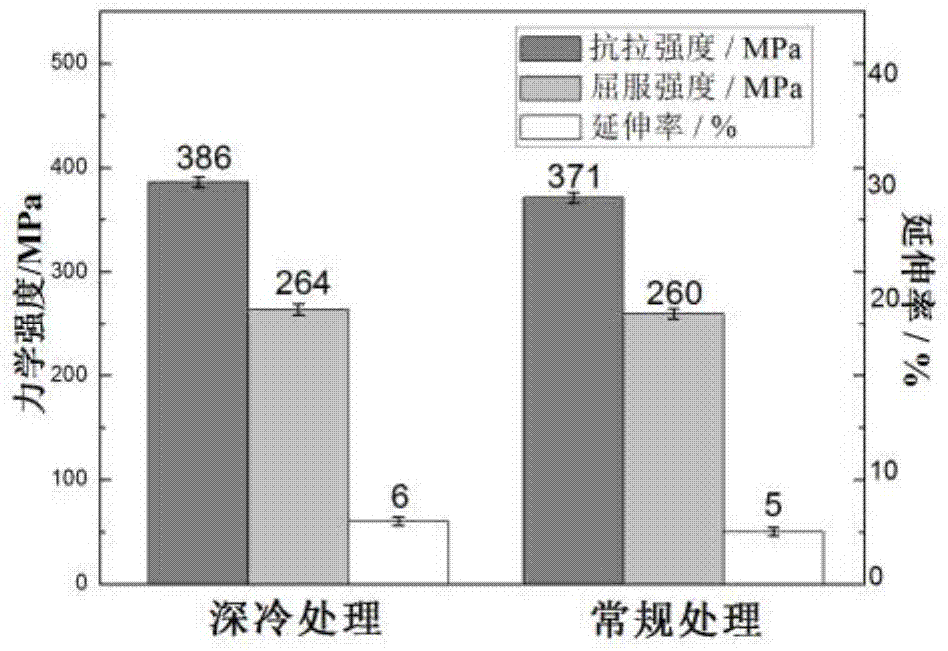

[0053] Carry out room temp...

Embodiment 3

[0057] Deformed Mg-7Y-1.5Nd-2Zn-0.5Zr

[0058] The deformed Mg-7Y-1.5Nd-2Zn-0.5Zr alloy is prepared in a conventional manner, and then the deformed Mg-7Y-1.5Nd-2Zn-0.5Zr alloy is solid solution treated at a solution temperature of 535°C and kept for 20 hours; After melting, the alloy is immediately taken out and placed in a liquid nitrogen environment for quenching, and kept in deep cooling for 12 hours; then, it is heated to 250°C for aging treatment, and the aging time is 12 hours; after aging, the alloy is immediately taken out and placed in a liquid nitrogen environment for quenching , kept in deep cold for 6h (see Figure 9 ). Depend on Figure 9 It can be seen that (a) is the microstructure of cryogenically treated Mg-7Y-1.5Nd-2Zn-0.5Zr alloy, and (b) is the microstructure of conventionally treated Mg-7Y-1.5Nd-2Zn-0.5Zr alloy. The structure of the alloy shows that the structure of the alloy after the cryogenic treatment of the present invention is better, and the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com