Compressor piston for balancing reciprocating motion inertia force

A technology of reciprocating motion and inertial force, which is applied in the direction of machines/engines, mechanical equipment, liquid variable displacement machinery, etc., can solve problems such as difficult to reach low-pressure pistons, compressors cannot run smoothly, and piston quality is not balanced, and achieve structural Reasonable, balanced quality, and the effect of ensuring smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

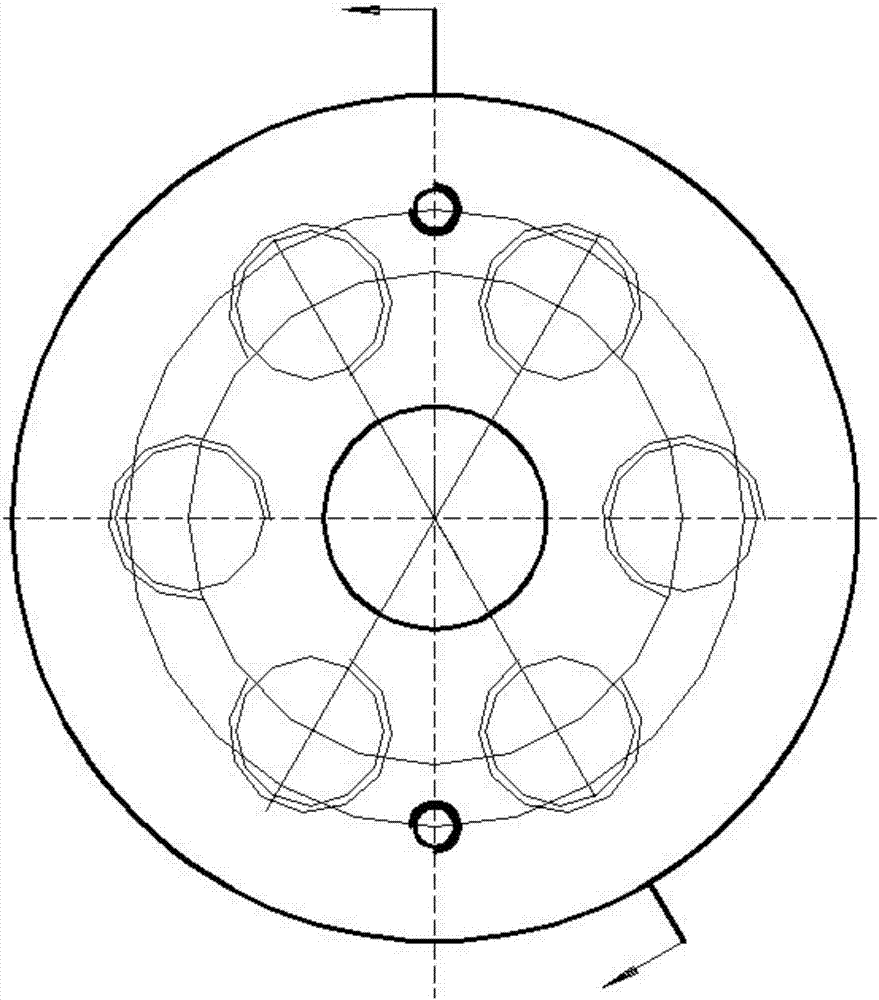

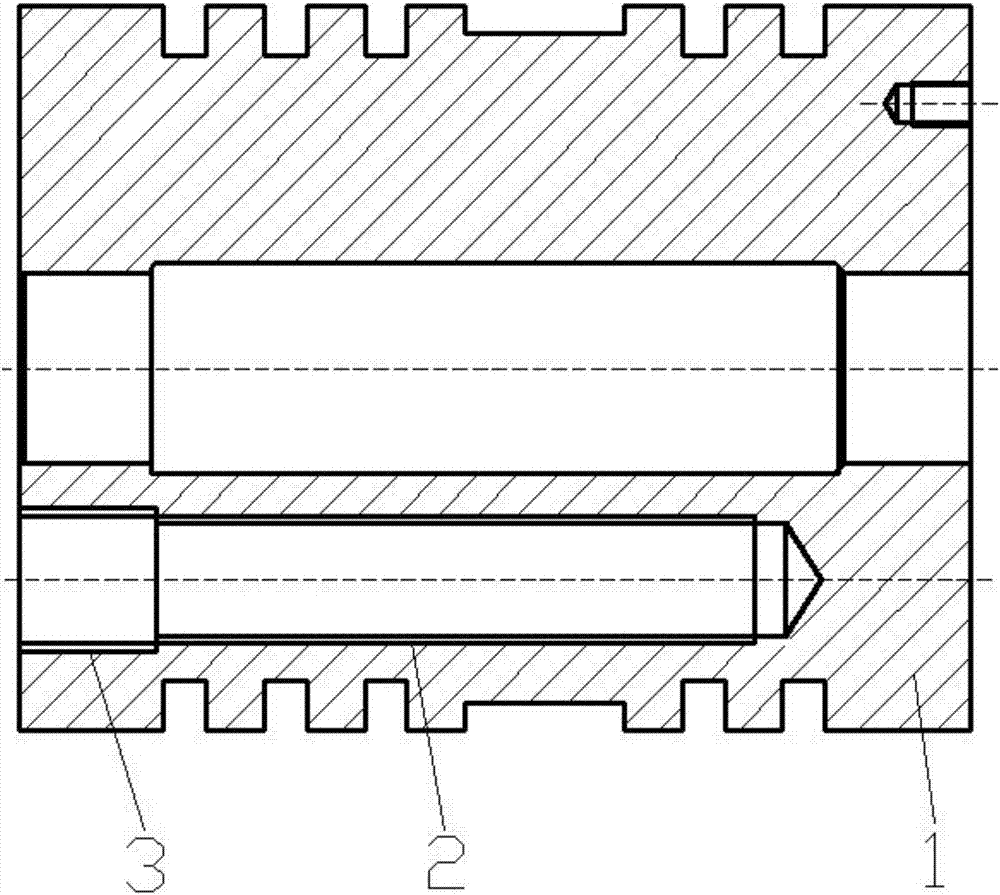

[0018] Reference Figure 1-3 , A compressor piston that balances the inertial force of reciprocating motion, comprising a piston body 1. The upper end surface of the piston body 1 is provided with two symmetrical screw holes, and the lower end surface of the piston body 1 is provided with 6 threaded holes. The threaded holes are perpendicular to the lower end surface of the piston body, and the threaded holes are counterbored structures, including small diameter threaded holes 2 and large diameter threaded holes 3. The threaded holes are distributed in a circular array based on the center of the through holes on the upper and lower ends of the piston body 1 .

[0019] The threaded hole is a counterbore structure, and the small diameter threaded hole 2 is drilled on the lower end surface of the piston body 1 first, and then the small diameter threaded hole 2 is enlarged in diameter, and the large diameter threaded hole 3 is drilled. Use lead as the filler, pour lead into the smal...

Embodiment 2

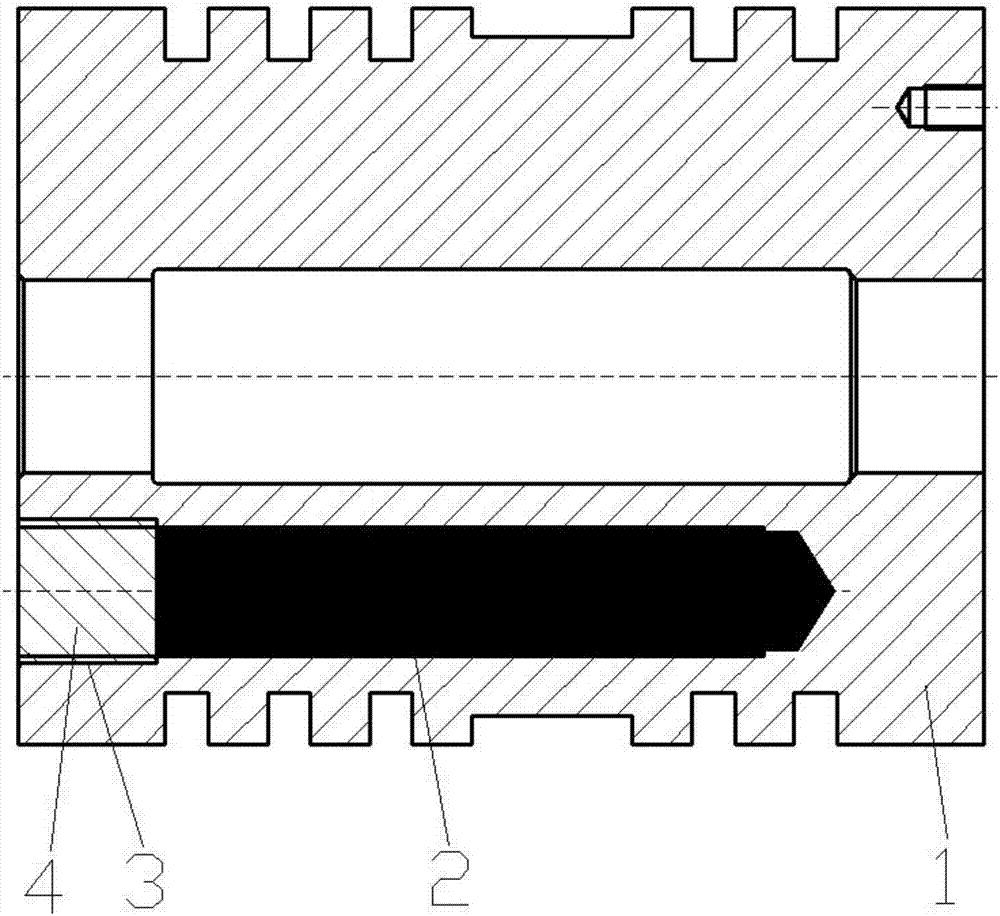

[0021] Reference Figure 1-3 , A compressor piston that balances the inertial force of reciprocating motion, comprising a piston body 1. The upper end surface of the piston body 1 is provided with two symmetrical screw holes, and the lower end surface of the piston body 1 is provided with 6 threaded holes. The threaded holes are perpendicular to the lower end surface of the piston body, and the threaded holes have a counterbore structure. The threaded holes are distributed in an annular array with the center of the through holes on the upper and lower ends of the piston body 1 as the base point.

[0022] The threaded hole has a counterbore structure. A counterbore drill is used to drill the threaded hole on the lower end of the piston body 1. The thickness of the head of the countersunk head bolt made of steel is the same, and then the countersunk head bolt and the inner wall of the threaded hole are coated with thread locking agent, and then tightened. Because the filling mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com