Multifunctional hemostatic agent and method for preparing same

A hemostatic agent, thrombin technology, applied in the fields of biochemical equipment and methods, blood diseases, pharmaceutical formulations, etc., can solve the problems of complex overall process, insufficient hemostasis and anti-adhesion effect, etc., to simplify the process, excellent hemostasis effect, Excellent morphological stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

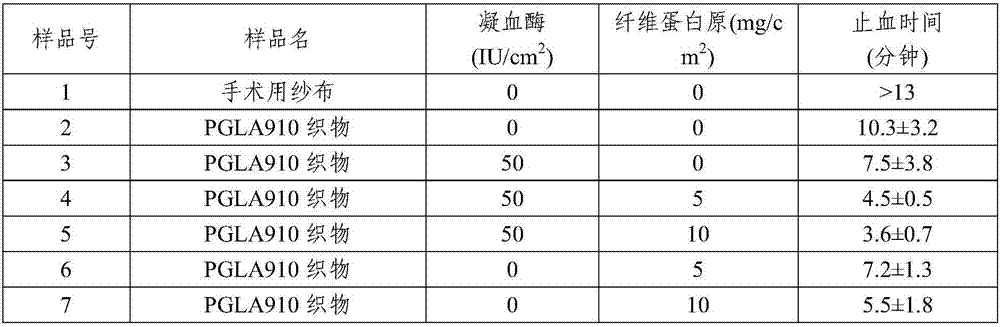

[0037] Preparation example 1: PGLA hemostatic agent alone

[0038] A fabric (5×7cm, 0.5g) made of biodegradable polymer PGLA910 fibers whose in vivo absorption time was adjusted to 14 days by gamma-ray irradiation was mixed with thrombin and / or fibrinogen as ingredients for promoting hemostasis. Immerse for a certain period of time in a solution of ingredients promoting hemostasis prepared by dissolving in a buffer solution with a pH of 8.0 to 8.5, and freeze-dry at a low temperature so that the activity of the ingredients promoting hemostasis will not be denatured, and vacuum at room temperature It was dried, then placed in an aluminum bag with nitrogen gas, and packed, thereby preparing a hemostatic agent. The amount of components promoting hemostasis present in the unit area of the prepared hemostatic agent is shown in Table 1 (sample No. 2 does not contain components promoting hemostasis).

preparation example 2

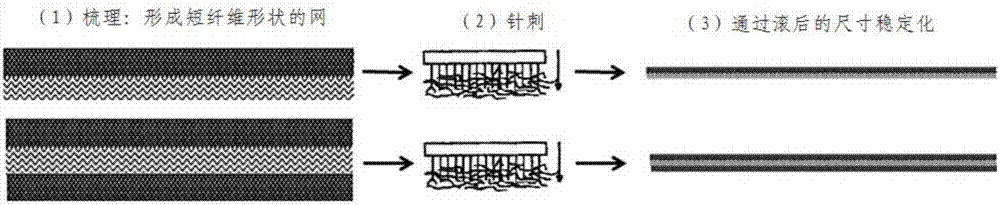

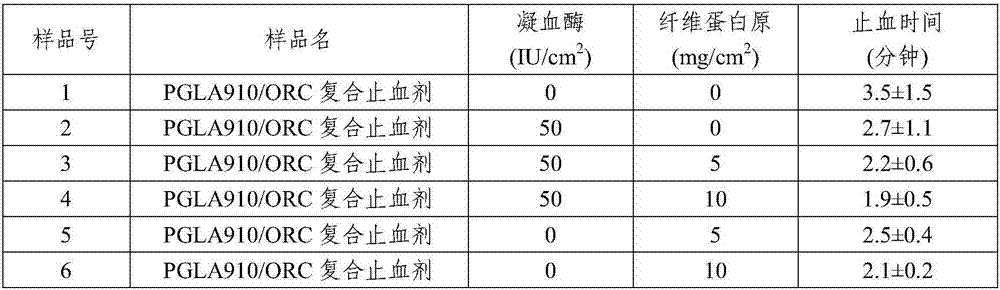

[0039] Preparation example 2: PGLA / ORC composite hemostatic agent

[0040] Fabrics prepared from PGLA910 fibers were prepared into fibrillar webs by carding and nonwovens by needling. A fabric (5 cm x 7 cm) made of PGLA910 fibers was dipped in a solution of components promoting hemostasis prepared by dissolving thrombin and / or fibrinogen as components promoting hemostasis in a buffer solution with a pH of 8.0 to 8.5. Time, freeze-drying at low temperature so that the activity of the components promoting hemostasis will not be denatured, and vacuum-drying at normal temperature. In addition, the oxidized regenerated cellulose (ORC) braided fabric is also made into a net through a carding process by the same method. A non-woven fabric made of PGLA910 fibers (5cm×7cm, 0.5g) and an ORC fibrous net (5cm×7cm, 0.5g) were overlapped and needle punched to make a nonwoven fabric, and a composite hemostat was made by a roller agent. The amount of components promoting hemostasis prese...

preparation example 3

[0041] Preparation example 3: PGLA / ORC composite hemostatic agent

[0042] A solution of collagen and / or gelatin, which is a component that promotes hemostasis, is freeze-dried into a powder form, and then included in a fabric made of PGLA910 fibers, which are biodegradable polymers. After that, the fabric of the PGLA910 fiber containing the hemostasis-promoting component was prepared into a web through a carding process. In addition, oxidized regenerated cellulose (ORC) braids were also prepared into webs by the same method. The prepared two kinds of nets were overlapped and needle-punched to make a non-woven fabric, which was passed through a roller to make a composite hemostat. The amount of components promoting hemostasis present in the unit area of the prepared hemostatic agent is shown in Table 3 (sample No. 1 does not contain components promoting hemostasis).

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com