Compositions of low-activation concretes and use thereof

A concrete, low-activation technology, applied in the fields of reactors, nuclear engineering, shielding, etc., can solve the problems of high related costs, reduce the radioactivity induced by concrete shielding, and achieve the effect of reducing radioactivity and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Example 1: Neutron Activation Analysis of Basic Concrete Components

[0088] Different samples of aggregate, sand and cement from different suppliers, ie from Lhoist, Sibelco, CBR, Holcim and Kerneos, were subjected to neutron activation analysis (NAA) using the BR1 nuclear reactor of SCK-CEN from Belgium.

[0089] Eu, Co and Cs concentrations in the basic concrete components were measured using a high-purity germanium spectrometer after two months of irradiation. The results are presented in Table 1.

[0090]

[0091]

[0092] Table 1: NAA measurements of Eu, Co and Cs concentrations in basic concrete components.

[0093] All irradiated limestone aggregates from Table 1 (indeed all high purity limestones) exhibit very low Eu, Co and Cs contents, almost all below 0.1 ppm or even lower. This indicates that high-purity limestone rock is an ideal aggregate for LAC.

[0094] White cement from CBR also contained low levels of impurities with an average Eu concentr...

Embodiment 2

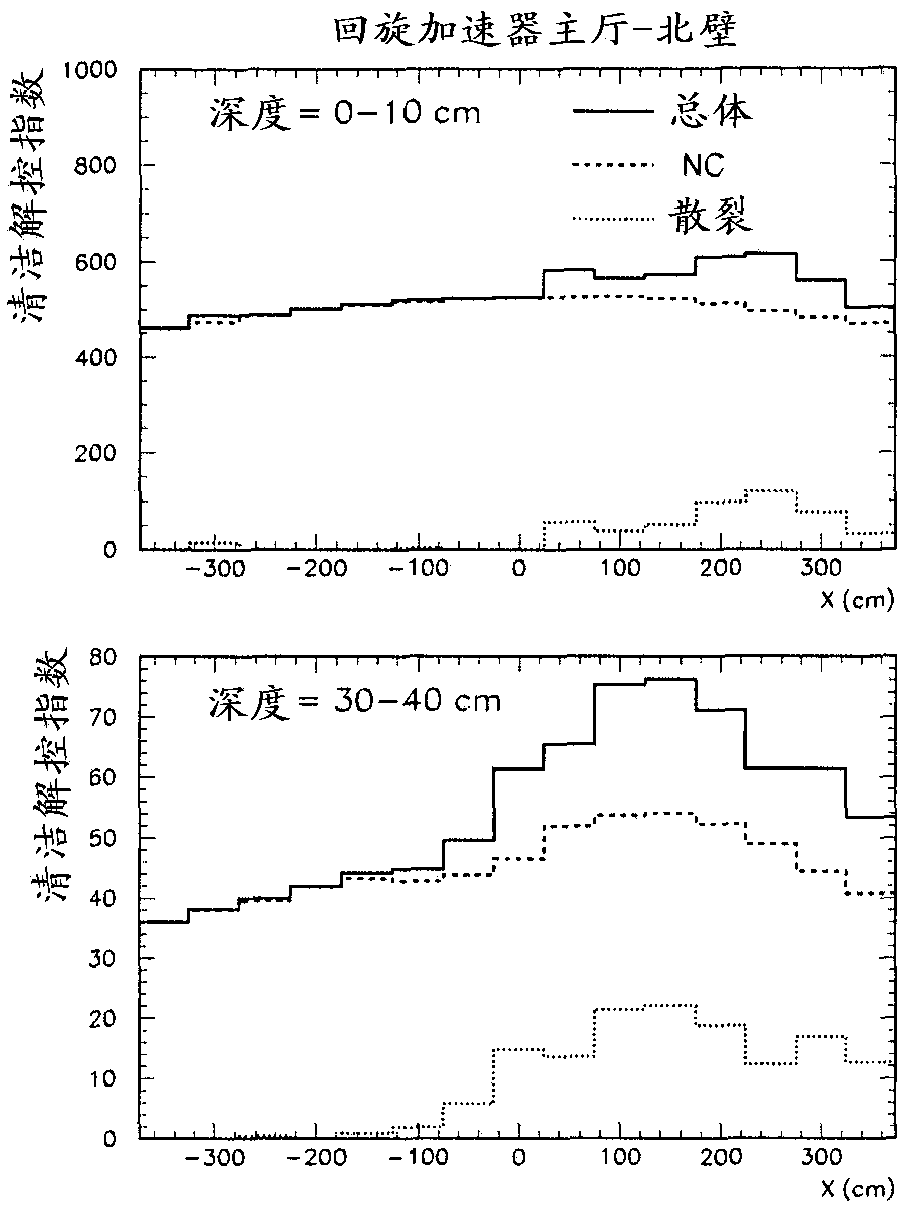

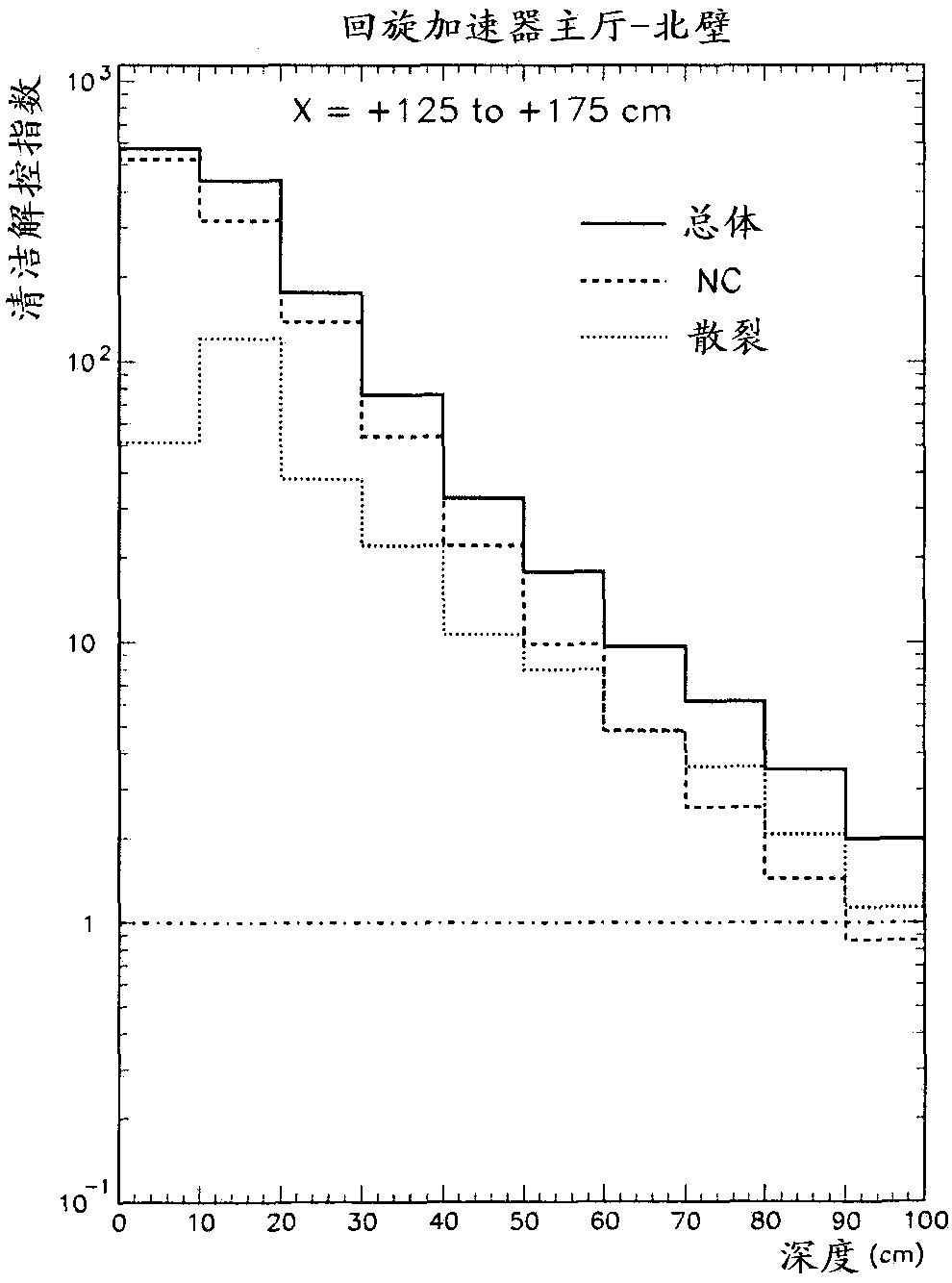

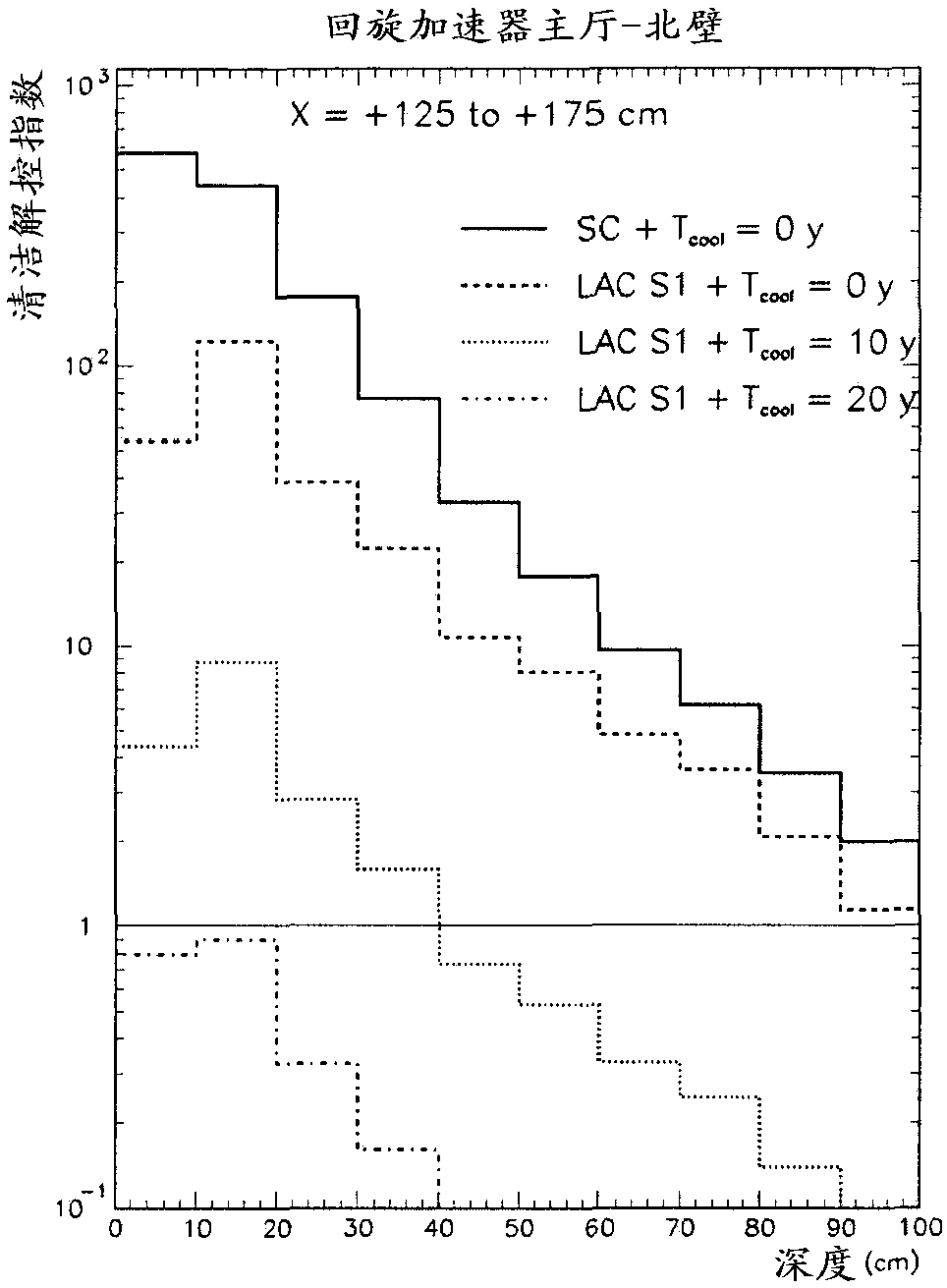

[0096] Example 2: Composition of low activation concrete

[0097] Based on the results from Table 1, the concrete compositions were formulated to minimize Eu, Co and Cs concentrations while maintaining the same physical properties as standard shielded concrete.

[0098] The first type of concrete LAC EI was made from 1914kg of high purity limestone aggregate combined with 260kg of white cement from CBR. Thus, the LAC El type sample contained (approximately) 88% by weight of high purity limestone aggregate. Two infused EI type LAC samples were prepared using two different types of white cement, namely white cement CEM I 42.5N or white cement CEM II / A-LL 42.5N.

[0099] The second type of concrete LAC S1 was made from 1815kg of high purity limestone aggregate combined with 400kg of Secar 71 aluminate cement from Kerneos. Thus, the LAC S1 type sample contained (approximately) 82% by weight of high purity limestone aggregate. A perfused S1 LAC sample was prepared.

[0100] T...

Embodiment 3

[0120] Example 3: Properties of Low Activation Concrete

[0121] physical properties

[0122] Different low-activation concrete samples were prepared and their physical properties were measured according to NBN standards (from the Belgian "Normalization Bureau" (NBN)).

[0123] The concrete formulations of the samples are given in Table 3.

[0124]

[0125] Table 3: Concrete formulations.

[0126] Reference sample 1 is a standard concrete sample based on Rhine sand, ordinary crushed limestone and lime cement.

[0127] The concentrations of Eu, Co and Cs in the concrete components of samples Nos. 2 to 4 are given in Table 1 of Example 1.

[0128] For formulations Nos. 1 to 3, based on gray cement (CEM III / A) or white cement (CEM I 42.5N, or CEM II / A-LL 42.5N), according to standards corresponding to environmental class EI, i.e. for reinforced concrete NBN EN 206 and NBN B15-001 requirements to determine cement and water dosage:

[0129] - per m 3 Concrete has a min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com