Microalgae culture method

A technology of microalgae culture and culture solution, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of inability to effectively increase the oil content of microalgae, reduce the greenhouse effect, save access costs, The effect of increasing content and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

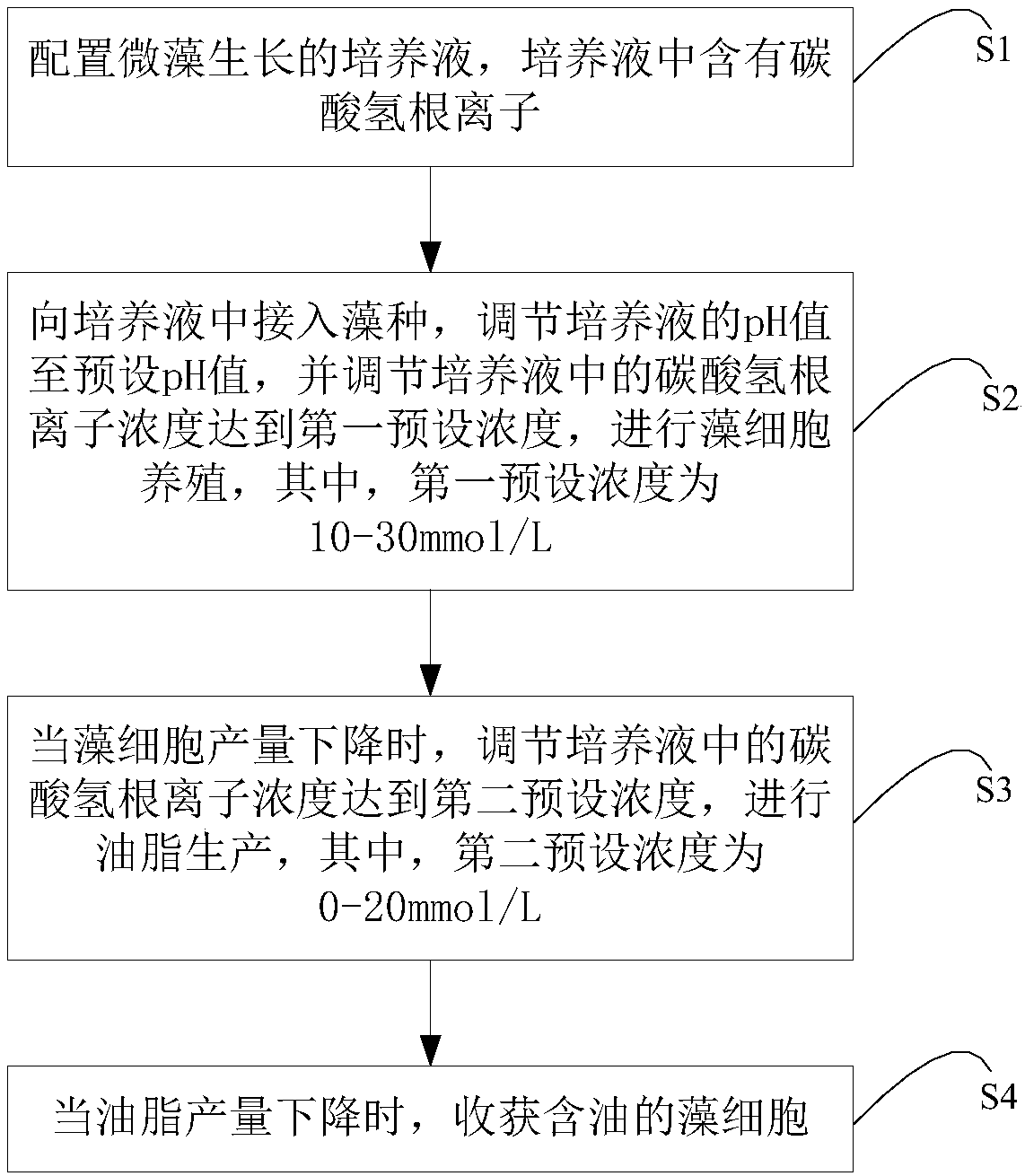

Method used

Image

Examples

Embodiment 1

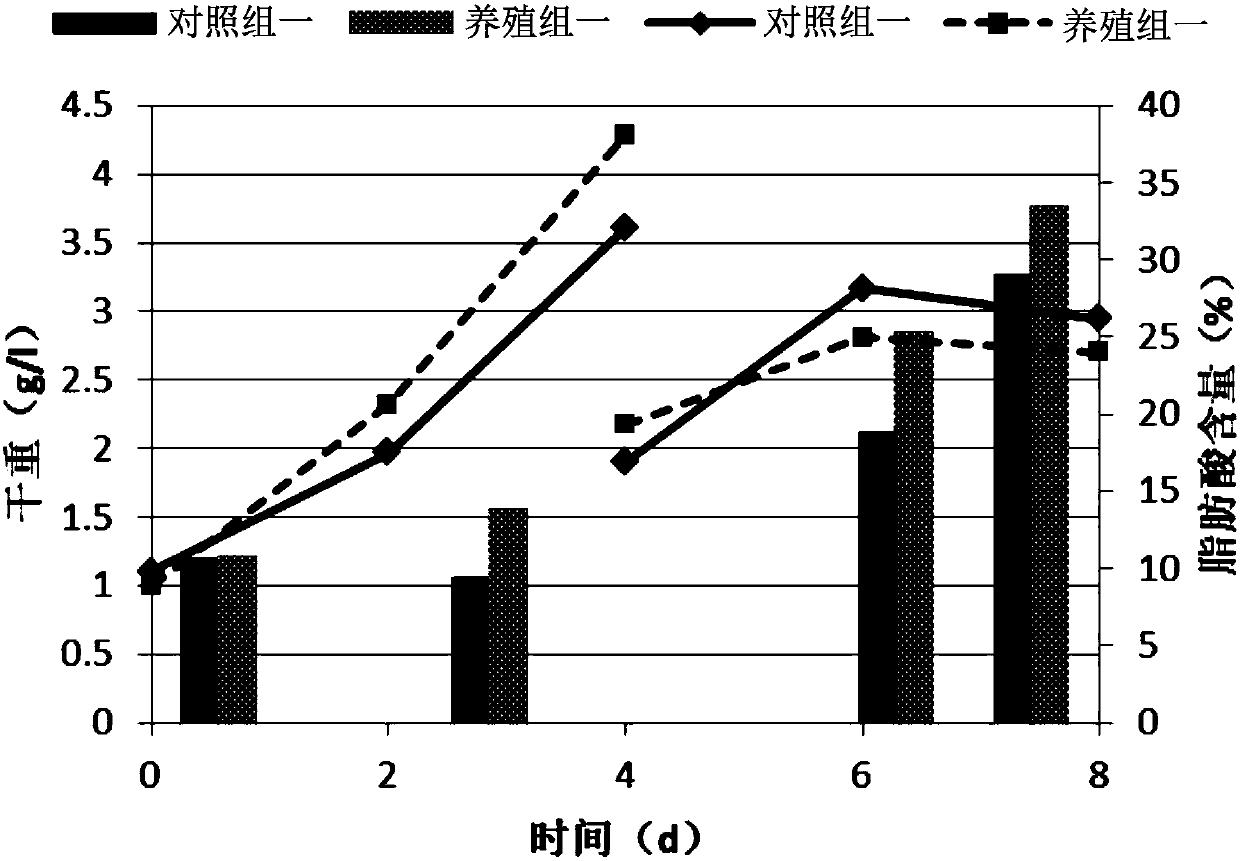

[0049] Both the control group 1 and the breeding group 1 inoculated a self-isolated algae species in the logarithmic growth phase in a 5cm optical path tube reactor, the light was 150μmol / ㎡ / s, 24 hours a day light, and the temperature was room temperature , the initial culture solution is the improved BG11 culture solution suitable for microalgae growth induction, and the formula of the improved BG11 culture solution is shown in Attached Table 1.

[0050] Breeding group one is to add 1g / L NaHCO to the initial culture medium 3 , then the bicarbonate ion concentration in the culture medium is about 12mmol / L. Introduce algae species into the prepared culture medium and start the cultivation of algae cells, and pass 2% CO into the culture medium 2 Mix air to adjust the pH of the culture medium to between 7 and 8. In the process of algae cell cultivation, monitor the ion concentration of bicarbonate in the culture medium, and adjust the CO in the mixed air according to the concen...

Embodiment 2

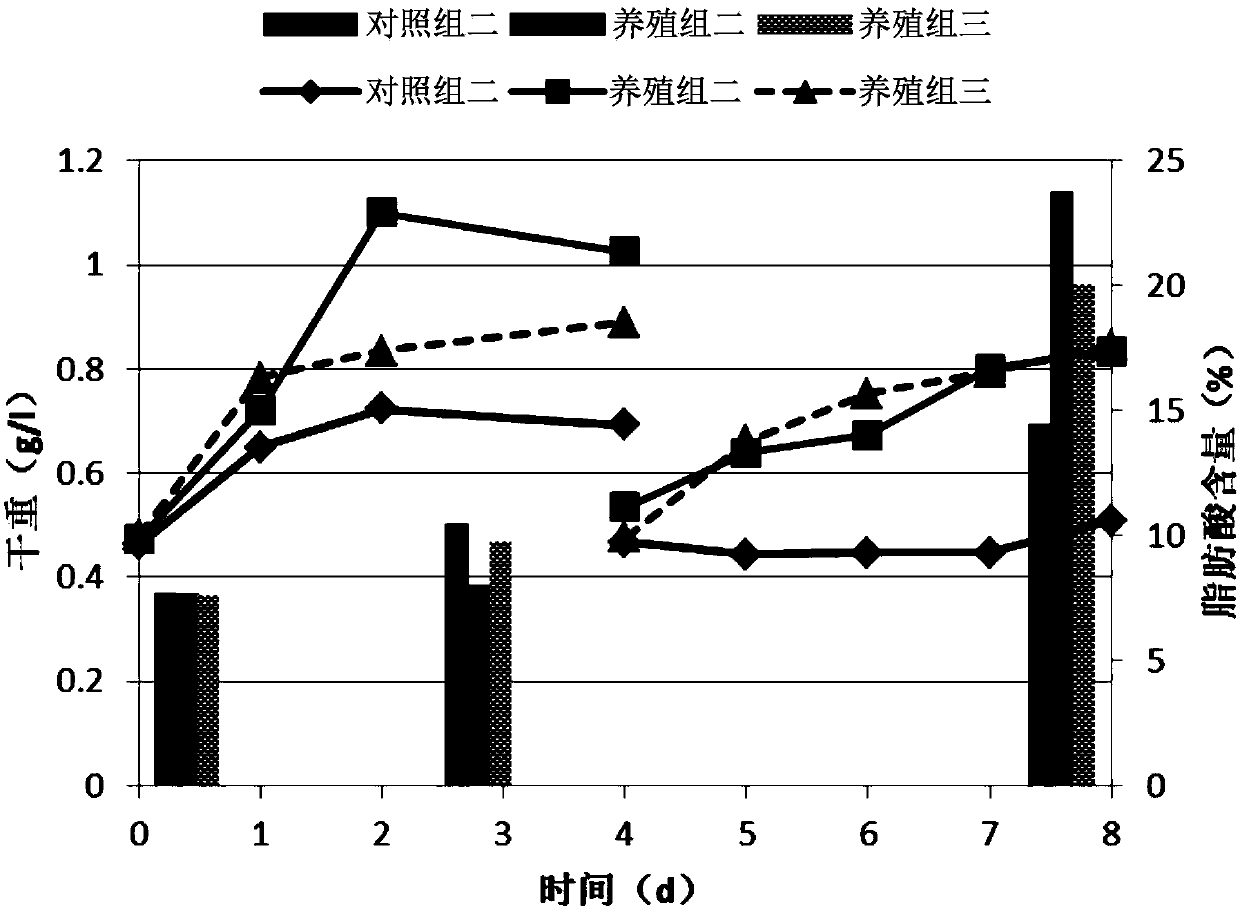

[0055] Control group 2, culture group 2 and culture group 3 all inoculated a strain of self-isolated algae in the logarithmic growth phase in a 5cm optical path tube reactor, the light was 150μmol / ㎡ / s, 8h: 16h light-dark cycle , the temperature is room temperature, and the initial culture solution is the improved BG11 culture solution suitable for the growth induction of the algae. The formula of the improved BG11 culture solution is shown in Attached Table 1.

[0056] Both culture group 2 and culture group 3 added 1.26g / L NaHCO to the initial culture medium 3 , then the bicarbonate ion concentration in the culture solution is about 15mmol / L. Breeding Group 2 and Breeding Group 3 both add algae species to the prepared culture medium and start culturing algae cells. Breeding Group 2 adds acetic acid to the culture medium to adjust the pH value of the culture medium to between 7-8 ; The culture group three added hydrochloric acid to the culture medium to adjust the pH value of ...

Embodiment 3

[0061] Control group 3, culture group 4 and culture group 5 all inoculated a strain of self-isolated algae in the logarithmic growth phase in a 0.2㎡ small track pool, with an optical path of 10cm and an illumination of 700μmol / ㎡ / s for 16h: 8h light and dark cycle, the temperature is room temperature, the initial culture medium is the improved BG11 medium suitable for microalgae growth induction, and the formula of the improved BG11 culture medium is shown in Attached Table 1.

[0062] Breeding group four is to add 0.84g / L NaHCO to the initial culture medium 3 , then the bicarbonate ion concentration in the culture medium is about 10mmol / L. Breeding group five is to add 1.68g / L NaHCO in the initial culture medium 3 , then the bicarbonate ion concentration in the culture solution is about 20mmol / L. Insert the algae species into the prepared culture medium and start the culture of the algae cells. Both the culture group 4 and the culture group 5 are injected with 10% CO2 into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com