Petroleum pipeline facilitating transportation and hoisting

A technology for oil pipelines and inner pipelines is applied in the field of oil pipelines that are easy to transport and hoist, and can solve the problems of heavy asphalt layer, increased pipeline load, poor thermal insulation effect, etc., to reduce burden, reduce weight, and achieve good thermal insulation and anti-corrosion effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

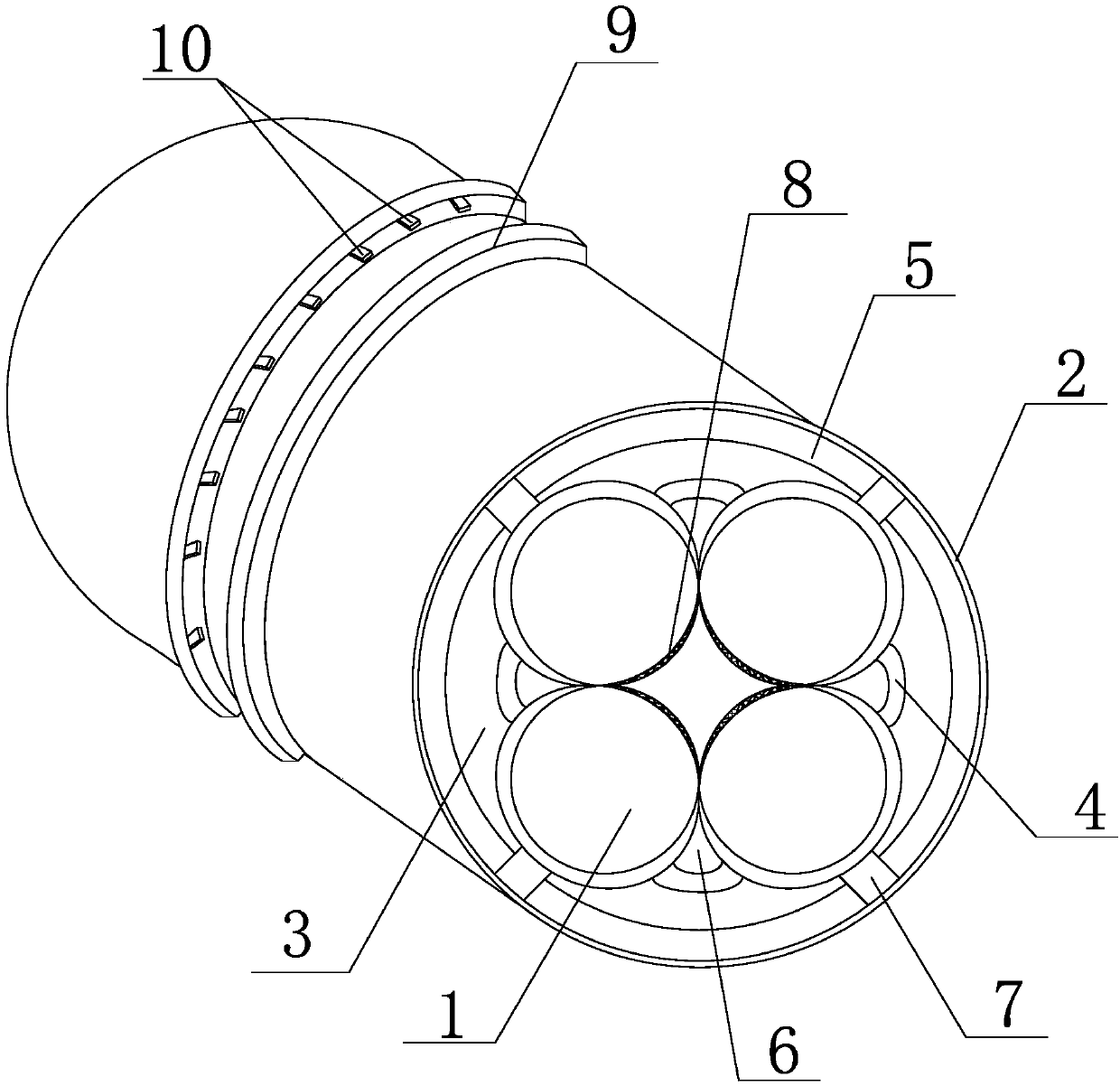

[0022] Such as figure 1 As shown, the present invention is a petroleum pipeline that is convenient for transportation and lifting. It includes an inner pipeline 1 and an outer pipeline 2 sleeved outside the inner pipeline 1. The shape of the inner pipeline 1 is four 3 / 4 circles connected end to end. The inner pipe 1 is provided with an insulation layer 3, the outer surface of the insulation layer 3 is circular, the insulation layer 3 is filled with glass wool, and the two 3 / 4 round pipes in the insulation layer 3 are between adjacent outer walls An arc-shaped reinforcing plate 4 is provided. A drying layer 6 is filled between the reinforcing plate 4 and the adjacent outer walls of two 3 / 4 round pipes. The drying layer 6 is filled with a desiccant, and the desiccant is evenly set There are pores, the reinforcing plate 4 is evenly provided with vent holes, an anti-corrosion layer 5 is provided between the insulation layer 3 and the outer pipe 2, and a filter screen 8 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com