Automated sprouting vegetable production line

A production line and technology of sprouted vegetables, applied in the field of automated sprouted vegetable production lines, can solve the problems of poor stability and safety, complex color adjustment, low production efficiency, etc., achieve the goal of increasing layer height, improving production efficiency, and reducing labor input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

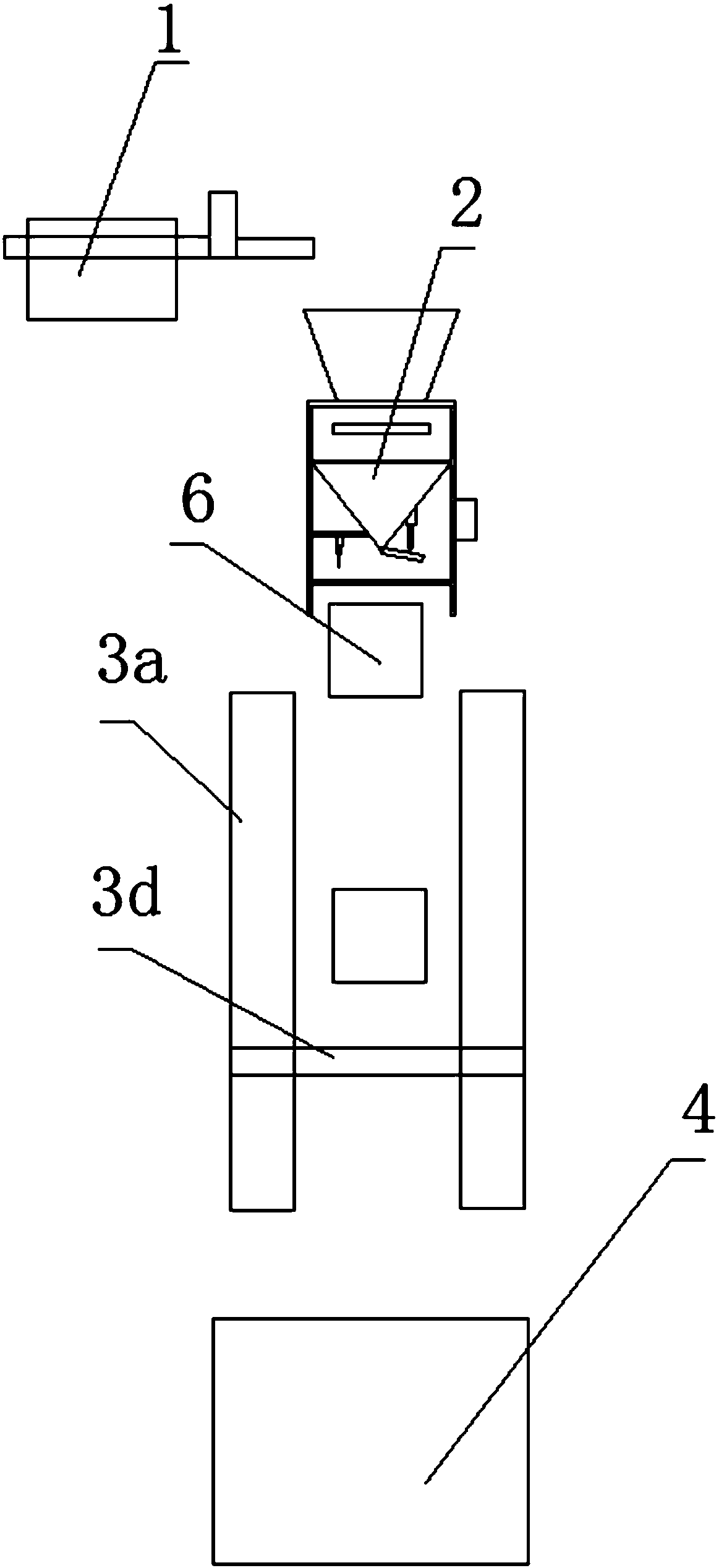

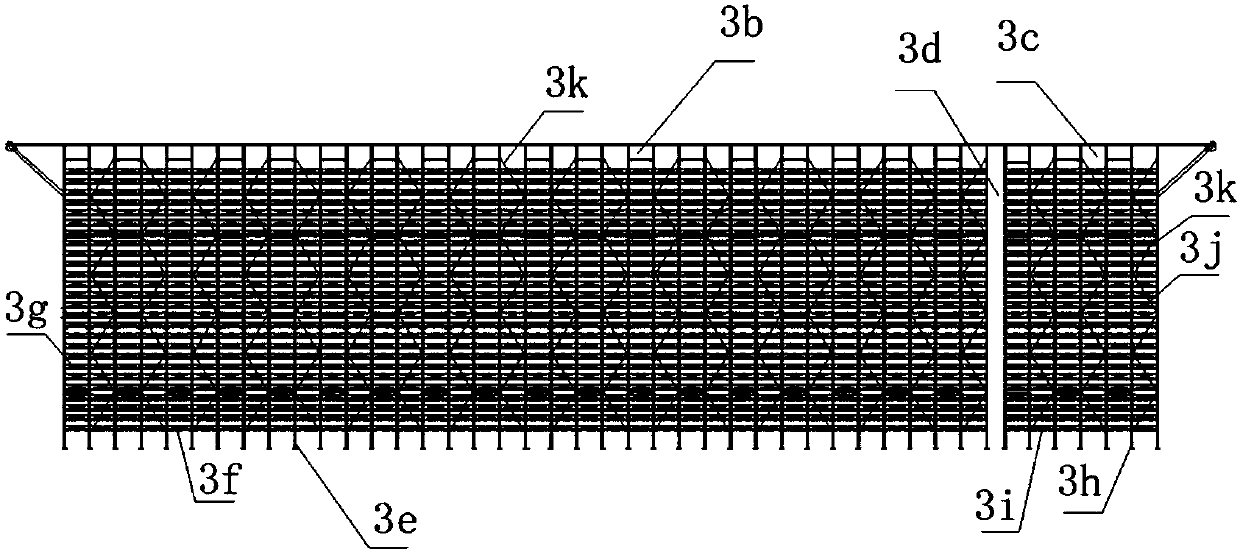

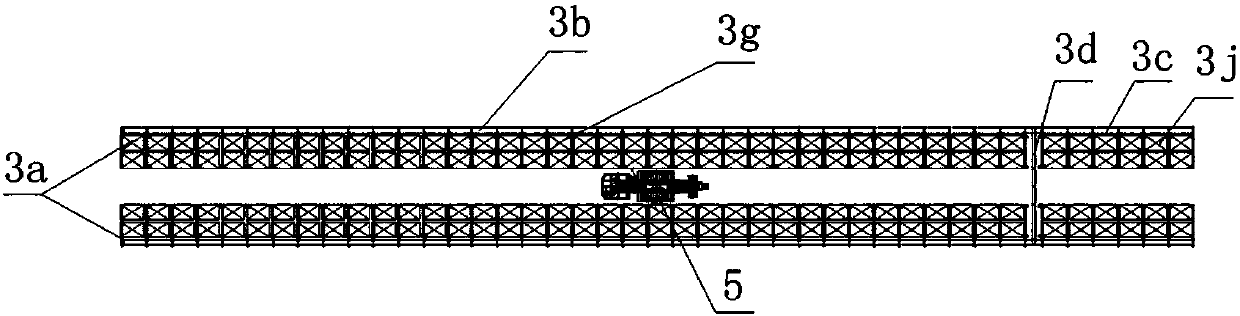

[0028] see Figure 1-10 , an automated production line for sprouts, comprising a seed soaker 1, a seeder 2, a cultivation frame 3, and a harvester 4 arranged in sequence.

[0029] Described seed soaking machine 1 comprises soaking pool 1a, is provided with the negative pressure turbine tube that communicates with negative pressure turbine on soaking pool 1a, is provided with plate chain conveyer belt 1b for transferring material in soaking pool 1a, and the outlet of soaking pool 1a is provided with cleaning device 1c, The cleaning device 1c communicates with the storage hopper 2c.

[0030] The seeder 2 includes a frame 2a, and the frame 2a is provided with a transfer chamber 2b, the transfer chamber 2b is a cuboid structure, and the side wall of the transfer chamber 2b is a transparent acrylic plate, which is convenient for the operator to observe the internal conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com