Method for preparation of vasicine and vitexin from adhatoda vasica

A technology for the preparation of orchidine and vitexin, which can solve the problems of poor extraction effect and difficult to meet the extraction requirements, so as to improve the dissolution rate and output, and reduce environmental waste possible, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

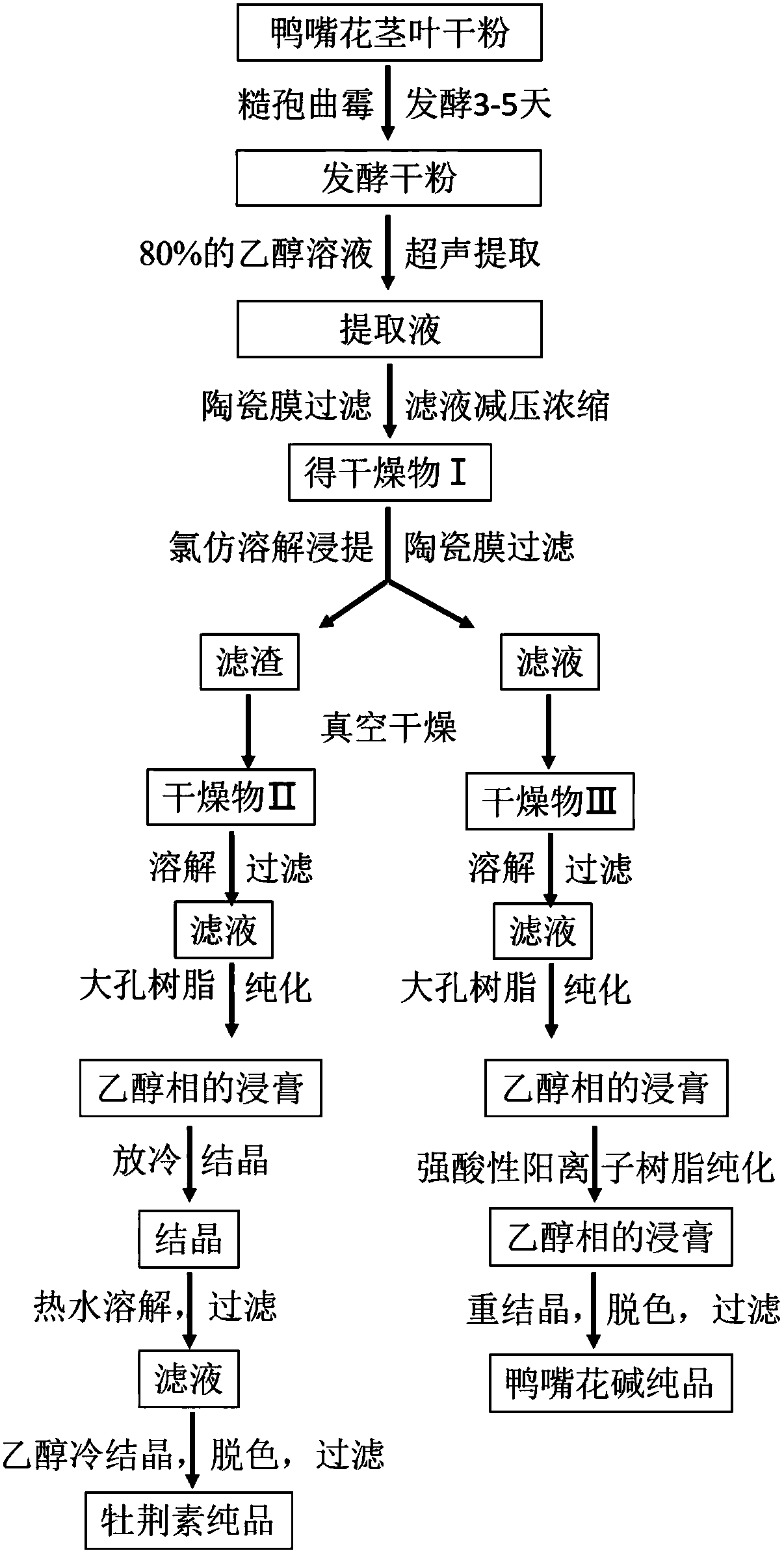

Image

Examples

Embodiment 1

[0031] Crush the dried duckbill flower stem and leaf raw materials to 10-20 mesh, weigh 100Kg, add 10L of Aspergillus crassasporium culture solution, and carry out aerobic solid fermentation at 28-30°C for 3-5 days. Add 800L of 80% ethanol solution to Duckbill flower after fermentation, ultrasonically extract 3 times at room temperature, 30 minutes each time, filter twice with three layers of gauze, filter once with ceramic membrane, combine the filtrate, concentrate the filtrate under reduced pressure and vacuum dry to remove ethanol , to obtain 6.2kg of dry matter I. The dried product I was leached with chloroform for 4-5 hours, filtered with a ceramic membrane, and the filter residue was vacuum-dried to obtain 1.41 kg of dried product II (flavone); the filtrate was concentrated under reduced pressure and vacuum-dried to remove chloroform, and dried to obtain 3.72 kg of dried product III. Dissolve the dried product II in water, filter with ceramic membrane, purify the filtra...

Embodiment 2

[0037] Crush the dried duckbill flower stem and leaf raw materials to 10-20 mesh, weigh 200Kg, add 15L Aspergillus crassasporium culture solution, and carry out aerobic solid fermentation at 28-30°C for 3-5 days. Add 1800L of 80% ethanol solution to Duckbill flower after fermentation, ultrasonically extract 3 times at room temperature, 30 minutes each time, filter twice with three layers of gauze, filter once with ceramic membrane, combine the filtrate, concentrate the filtrate under reduced pressure and vacuum dry to remove ethanol , to obtain 11.4kg of dry matter I. The dried product I was leached with chloroform for 4-5 hours, filtered with a ceramic membrane, and the filter residue was vacuum-dried to obtain 2.78 kg of dried product II (flavone); the filtrate was concentrated under reduced pressure and vacuum-dried to remove chloroform, and dried to obtain 7.41 kg of dried product III. Dissolve the dried product II in water, filter with ceramic membrane, purify the filtrat...

Embodiment 3

[0040] Crush the dried duckbill flower stem and leaf raw materials to 10-20 mesh, weigh 5Kg, add 0.5L Aspergillus crassasporium culture solution, and carry out aerobic solid fermentation at 28-30°C for 3-5 days. Add 40L of 80% ethanol solution to Duckbill flower after fermentation, ultrasonically extract 3 times at room temperature, 30 minutes each time, filter twice with three layers of gauze, filter once with ceramic membrane, combine the filtrate, concentrate the filtrate under reduced pressure and vacuum dry to remove ethanol , to obtain 295g of dry matter I. The dried product I was leached with chloroform for 4-5 hours, filtered with a ceramic membrane, and the filter residue was vacuum-dried to obtain 70.2 g of dried product II (flavone); the filtrate was concentrated under reduced pressure and vacuum-dried to remove chloroform, and dried to obtain 192 g of dried product III. Dissolve the dried product II in water, filter with ceramic membrane, purify the filtrate with D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com