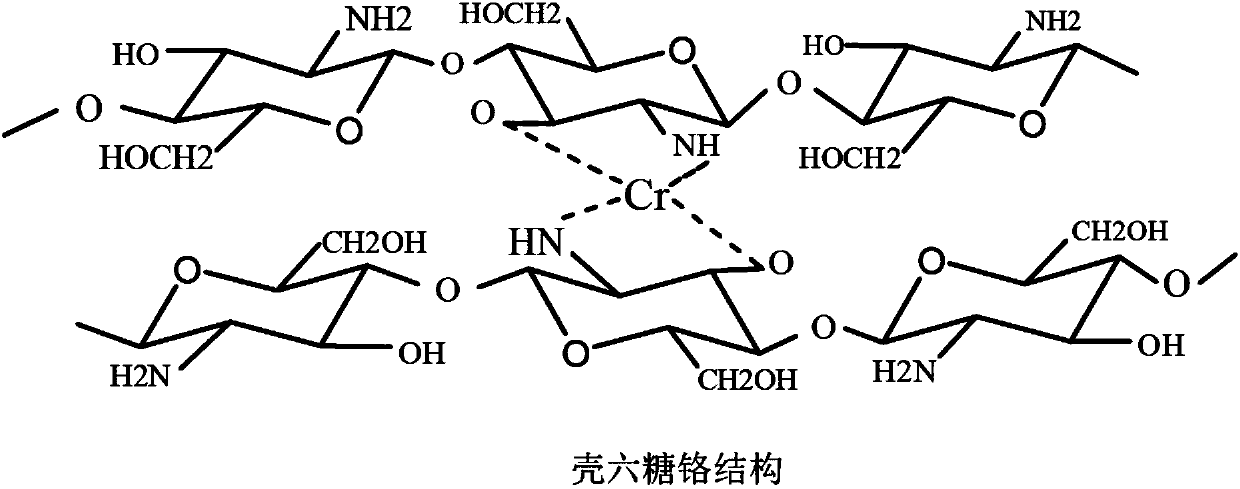

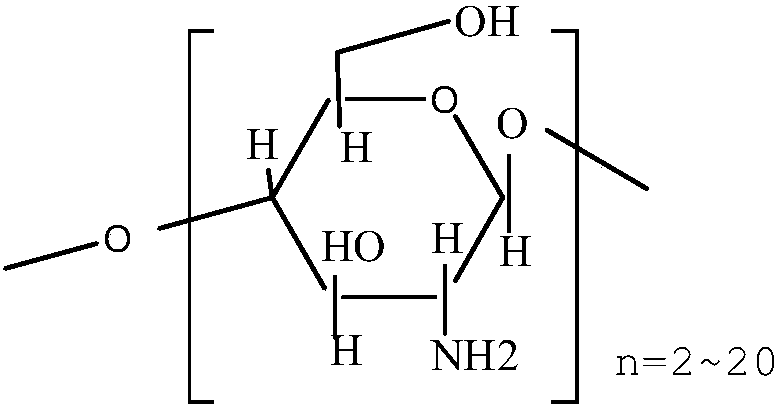

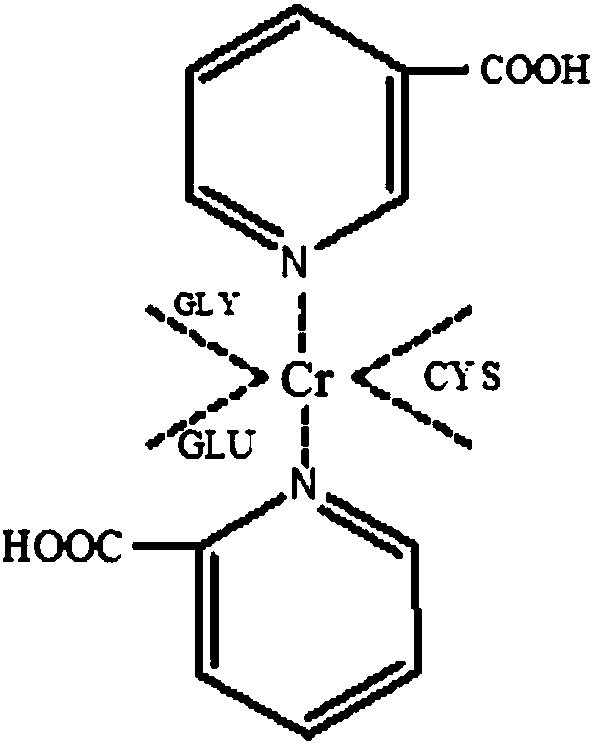

Preparation method for chitohexaose hydrochloride to octasaccharide chrome complex

A technology of chromium complex and chitohexaose is applied in the field of preparation of chitosan oligosaccharide complex, can solve the problems of low degree of polymerization, high price, unfavorable industrialized production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of chitosexaose to octaose chromium complex comprises the following steps:

[0043] Step 1: Chitosan with a deacetylation degree of more than 90% is formulated with 1% acetic acid solution into 5% chitosan acetic acid solution,

[0044] Step 2 Under the conditions of pH 5.5 and temperature 55°C, add a compound enzyme preparation consisting of cellulase and papain at a concentration of 0.05% with a mass ratio of 1:1, and perform enzymatic hydrolysis for 5 hours.

[0045] Step 3. Heat up to 70°C and keep the enzyme inactivated for 45 minutes. After cooling to room temperature, filter for the first time: filter with qualitative filter paper, adjust the pH of the filtrate to 7.5, and heat to 50°C to obtain the primary filtrate. Separation and purification: the molecular weight cut-off MWCO is 3KDa The ultrafiltration membrane was separated and purified at a circulating temperature of 50°C to obtain the permeate, and the third filtration: the permeate wa...

Embodiment 2

[0051] A preparation method of chitosexaose to octaose chromium complex comprises the following steps:

[0052] Step 1: Chitosan with a deacetylation degree of more than 70% is formulated with 1% acetic acid solution into 5% chitosan acetic acid solution,

[0053] Step 2 Under the conditions of pH 5.5 and temperature 55°C, add a compound enzyme preparation composed of cellulase and papain at a concentration of 0.05% in a mass ratio of 1:1, and perform enzymatic hydrolysis for 6 hours.

[0054] Step 3: heat up to 80°C for 30 minutes to inactivate the enzyme, cool to room temperature and then filter for the first time: filter with qualitative filter paper, adjust the pH of the filtrate to 8, heat to 50°C to obtain the primary filtrate, separate and purify: take the molecular weight cut-off as 1.5KDa The ultrafiltration membrane was separated and purified at a cycle temperature of 50°C to obtain the permeate, and the third filtration: the permeate was a negatively charged nanofil...

Embodiment 3

[0059] A preparation method of chitosexaose to octaose chromium complex, is characterized in that, comprises the following steps:

[0060] Step 1: the chitosan with a deacetylation degree of more than 55% is prepared with a concentration of 2% acetic acid solution into a 5% chitosan acetic acid solution;

[0061] Step 2. Under the conditions of pH 5.5 and temperature 55°C, add a compound enzyme preparation of cellulase, papain and lipase with a concentration of 0.05% in a mass ratio of 5:4:1 to carry out enzymolysis reaction. Solution reaction time 7h;

[0062] Step 3: Raise the temperature to inactivate the enzyme reaction, cool to room temperature, filter, separate and purify the enzymolysis liquid, filter once, filter with qualitative filter paper, adjust the pH of the filtrate to 8, heat to 50°C to obtain the primary filtrate, separate and purify the primary filtrate The filtrate was separated and purified with an ultrafiltration membrane with a molecular weight cut-off o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com