A coating solution for improving water drop angle and surface smoothness of protective film and preparation method thereof

A technology with smooth surface and protective film, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of high cost, poor durability of hydrophobic surface, complicated process of hydrophobic surface, etc. Corner elevation, hydrophobicity enhancement, high antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

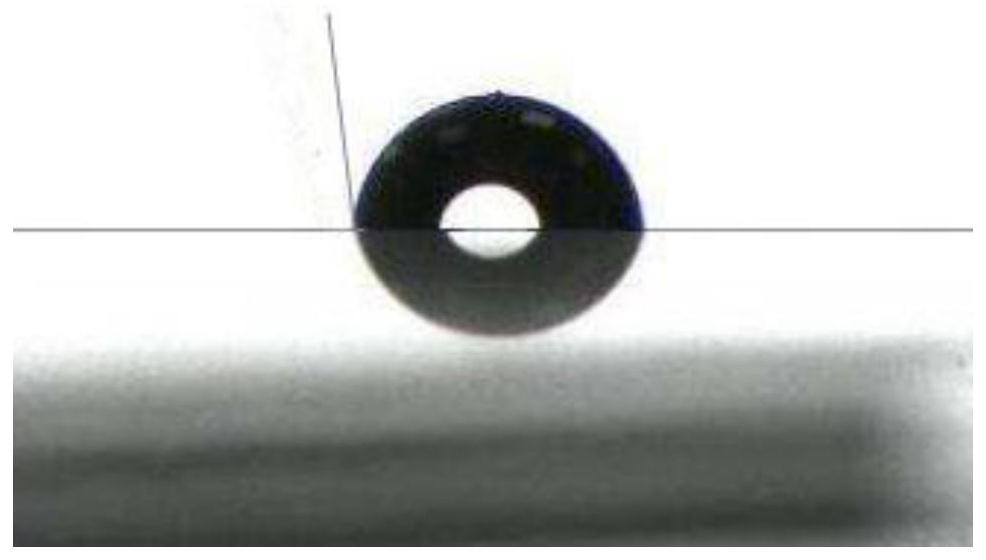

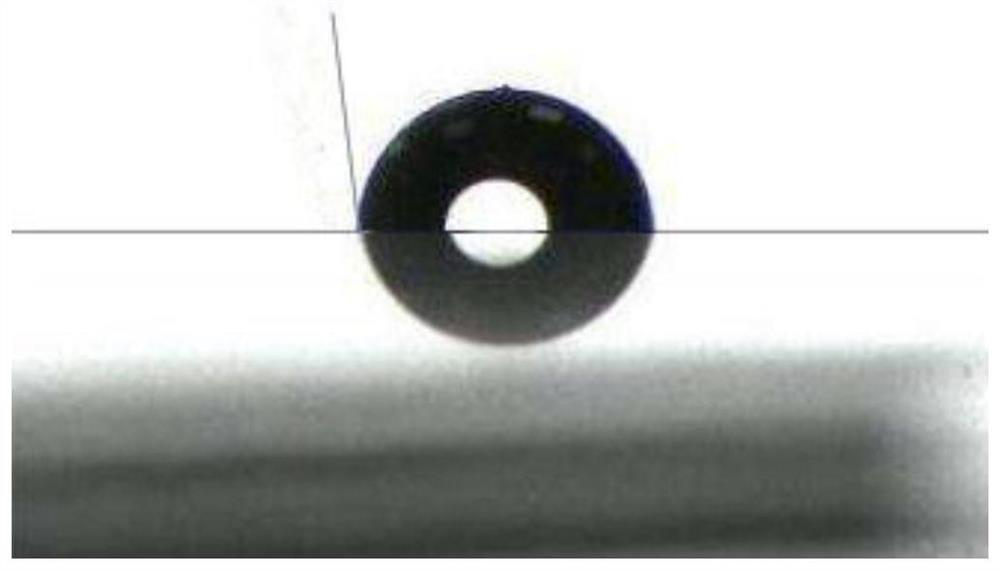

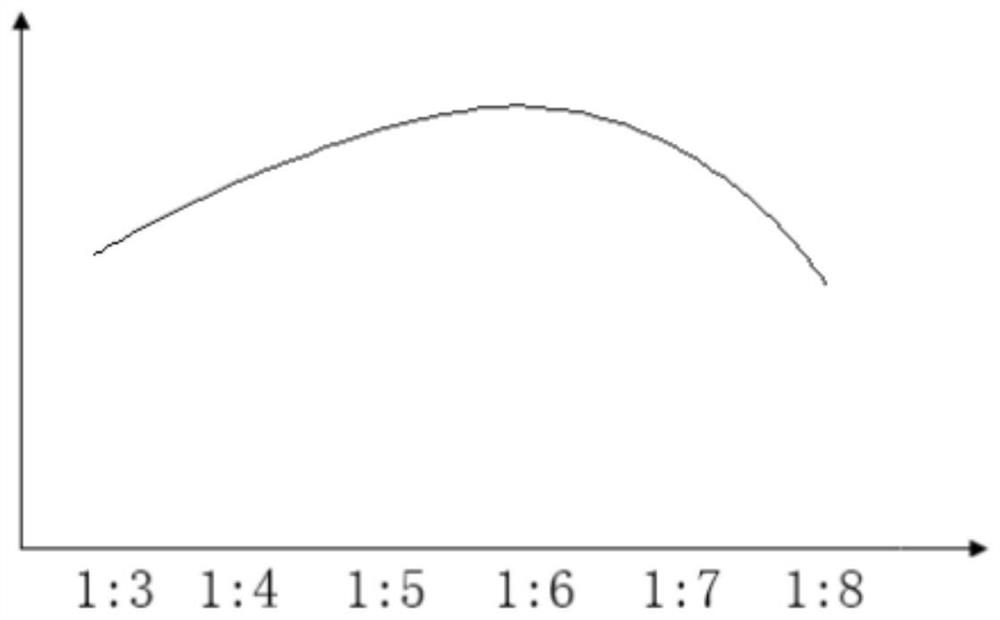

Image

Examples

Embodiment 1

[0042] A coating solution for improving the water drop angle and surface smoothness of the protective film, comprising 85.5 parts of simethicone oil A with a viscosity of 100cst; 14.2 parts of simethicone B with a viscosity of 200cst; 0.08 part of alcohol dye solution and 0.24 part of essence, The concentration of the dye in the alcohol dye solution is 35wt%.

[0043] The preparation method of the coating solution for improving the water drop angle and surface smoothness of the protective film comprises the following steps:

[0044] 1) Add simethicone oil A to the reactor with agitator, and add an acidic catalyst to make the viscosity of simethicone oil A 95-105cst;

[0045] 2) Add simethicone oil B to the reactor with agitator, and add an acidic catalyst to make the viscosity of simethicone oil B 195-205cst;

[0046] 3) Add the solution obtained in step 2) dropwise to step 1), and stir at a constant speed of 1000r / min;

[0047] 4) Add the dye alcohol solution of the formula...

Embodiment 2

[0051] A coating solution for improving the water drop angle and surface smoothness of the protective film, comprising 85.5 parts of simethicone oil A with a viscosity of 100cst; 14.2 parts of simethicone B with a viscosity of 200cst; 0.06 part of alcohol dye solution and 0.24 part of essence, The concentration of the dye in the alcohol dye solution is 35wt%.

[0052] The preparation method of this coating liquid comprises the following steps:

[0053] 1) Add simethicone oil A to the reactor with agitator, and add an acidic catalyst to make the viscosity of simethicone oil A 95-105cst;

[0054]2) Add simethicone oil B to the reactor with agitator, and add an acidic catalyst to make the viscosity of simethicone oil B 195-205cst;

[0055] 3) Add the solution obtained in step 2) dropwise to the solution in step 1), and stir at a constant speed of 1000r / min to obtain a mixed solution;

[0056] 4) Add the dye alcohol solution of the formula amount to the mixed solution after step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com