Apparatus and method for comprehensive utilization of thermal energy in chlorine dioxide pulp bleaching

A chlorine dioxide, pulp bleaching technology, applied in pulp bleaching and other directions, can solve problems such as more consumption, achieve the effects of energy saving and environmental protection costs, reducing steam consumption, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

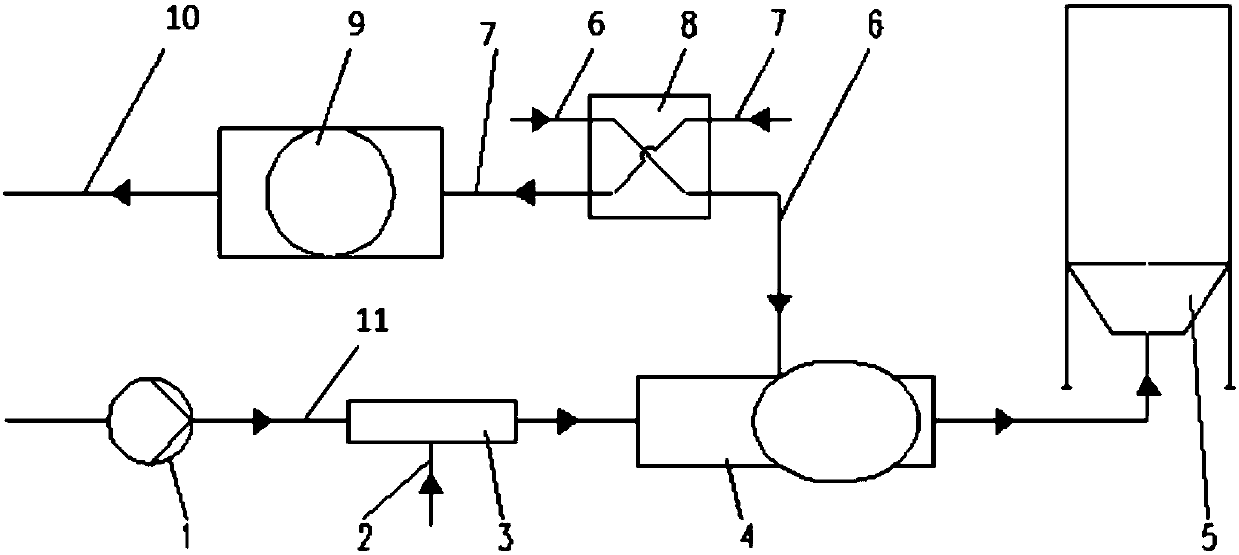

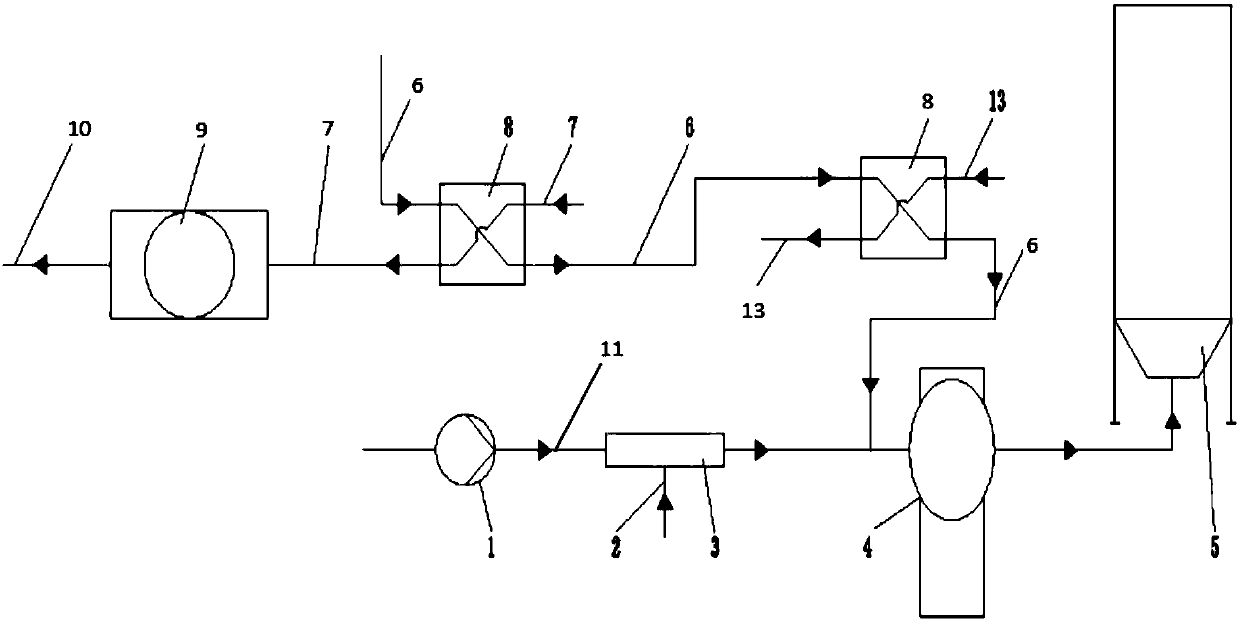

[0033] Such as figure 1 Shown, a chlorine dioxide pulp bleaching heat energy comprehensive utilization device, including pulp pump (1), steam heater (3), mixer (4), bleaching tower (5), heat exchanger one (8), ice water machine (9), the pulp pump (1) is connected to the inlet of the steam heater (3) through the pulp conveying pipe (11), and the outlet of the steam heater (3) is connected to the inlet of the mixer (4) through the pulp conveying pipe (11), The outlet of the mixer (4) is connected to the inlet of the bleaching tower (5) through the pulp conveying pipe (11), the chlorine dioxide conveying pipe (6) is connected to the inlet of the heat exchanger one (8), and passes through the outlet of the heat exchanger one (8) It is connected with the mixer (4), and the process water delivery pipe (7) is connected to the inlet of heat exchanger one (8), and connected to the chiller (9) through the outlet of heat exchanger one (8).

[0034] A method for comprehensive utilization...

Embodiment 2

[0040] Such as figure 1 Shown, a kind of chlorine dioxide pulp bleaching heat energy comprehensive utilization device, on the basis of embodiment 1, steam heater (3) inlet is connected with steam adding pipe (2), ice water machine (9) outlet is connected with ice water delivery Tube (10).

[0041] A method for comprehensive utilization of chlorine dioxide pulp bleaching heat energy using the above-mentioned device, the specific steps are as follows:

[0042] Step 1, pulp conveying, the pulp in the pulp conveying pipe (11) is pumped to the steam heater (3) through the pulp pump (1), and the steam is added into the steam heater (3) through the steam adding pipe (2) to process the pulp Transport to mixer (4) after heating;

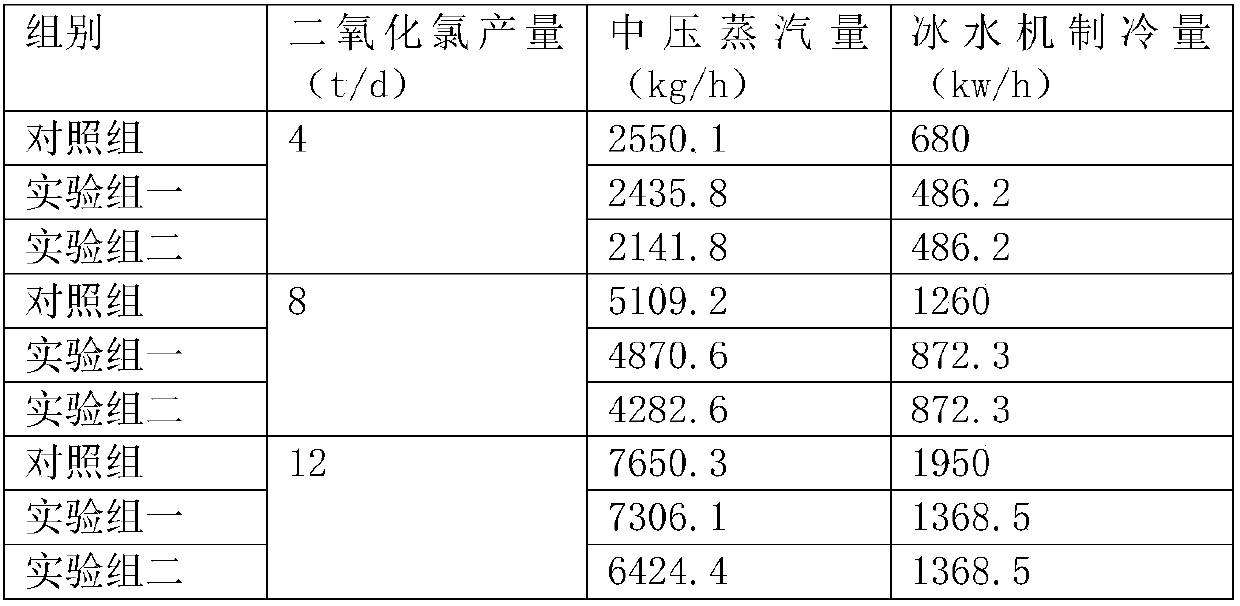

[0043] Step 2, heat exchange, process water at 30°C normal temperature enters heat exchanger one (8) through process water delivery pipe (7), 13°C low-temperature chlorine dioxide aqueous solution enters heat exchanger one through chlorine dioxide delivery ...

Embodiment 3

[0047] Such as figure 1 Shown, a kind of chlorine dioxide pulp bleaching heat energy comprehensive utilization device, on the basis of embodiment 1, steam heater (3) inlet is connected with steam adding pipe (2), ice water machine (9) outlet is connected with ice water delivery Tube (10).

[0048] A method for comprehensive utilization of chlorine dioxide pulp bleaching heat energy using the above-mentioned device, the specific steps are as follows:

[0049] Step 1, pulp conveying, the pulp in the pulp conveying pipe (11) is pumped to the steam heater (3) through the pulp pump (1), and the steam is added into the steam heater (3) through the steam adding pipe (2) to process the pulp Transport to mixer (4) after heating;

[0050] Step 2, heat exchange, 28 ℃ normal temperature process water enters heat exchanger 1 (8) through process water delivery pipe (7), 15 ℃ low-temperature chlorine dioxide aqueous solution enters heat exchanger 1 through chlorine dioxide delivery pipe (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com