Filling system and method for LNG filling station

A technology for filling systems and filling stations, applied in the field of filling systems for LNG filling stations, which can solve problems such as long time consumption, low filling efficiency, and high loss of LNG liquid, and achieve high efficiency, easy operation, and saving The effect of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

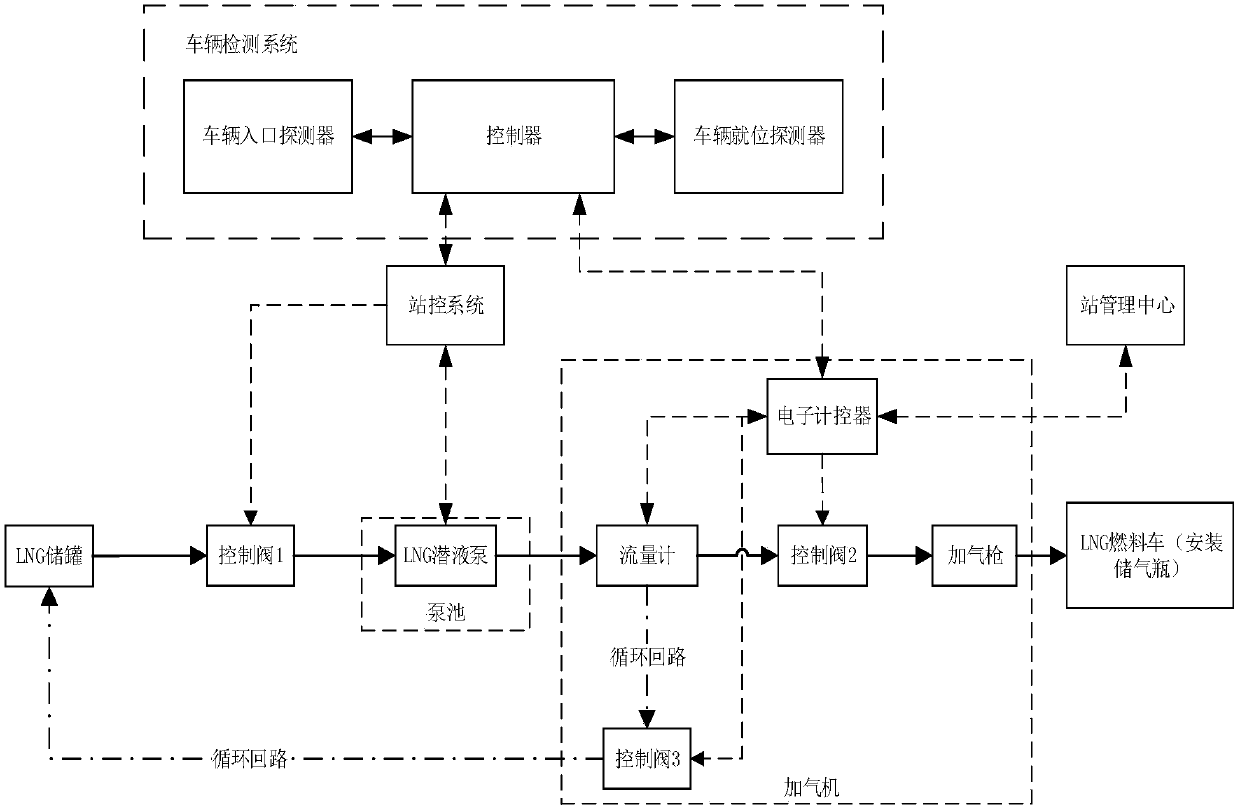

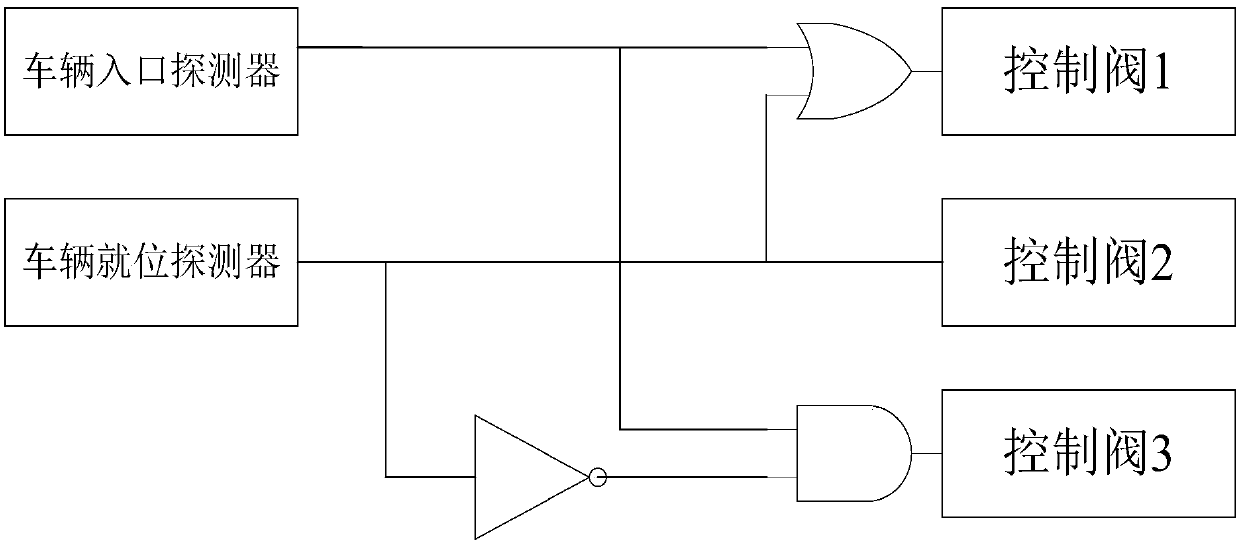

[0049] Such as Figure 1~2 As shown, a filling system and method thereof for an LNG filling station of the present invention includes at least one filling machine, and the filling machine includes a sequentially connected LNG storage tank, a control valve 1, an LNG submersible pump, and a flow meter , a control valve 2, an air filling gun, and an electronic controller connected with a flow meter and a control valve 3, the electronic controller is connected with the control valve 2, and the control valve 3 is connected with the LNG storage tank and the electronic controller The electronic controller is connected with a controller; it is characterized in that it also includes a station control system and a vehicle detection system, and the station control system is connected with the control valve 1, the LNG submersible pump and the controller respectively, and the The vehicle detection system is used to obtain the vehicle signal of the vehicle at the entrance and the gas fillin...

Embodiment 2

[0054] The filling method of a kind of LNG gas filling station includes system standby process, cycle pre-cooling process and filling process;

[0055] When Tn is greater than T m , the system starts the system standby process; T n After the vehicle entrance detector detects the entry of the vehicle, it sends a signal to the controller. After the controller analyzes and processes, it sends a signal to the station control system. The station control system sends a start precooling signal and adds 1 to the vehicle counter m in the controller. Started timing pre-cooling waiting time; T m Be the maximum waiting time of the circulation precooling flow process of the present invention, described T m is 4 minutes;

[0056] When Tz is less than or equal to Ty, the dispenser starts the filling process at Ty time; T z After the vehicle presence detector detects the vehicle signal, the electronic controller sends a refueling command to the station control system to make the system en...

Embodiment 3

[0067] The filling method of a kind of LNG filling station, on the basis of embodiment 2, the station control system monitors the temperature of the pump pool in the circulating pre-cooling process at the same time, the controller obtains the temperature information, and obtains the temperature information of each pump pool through analysis and comparison. The temperature is sorted from low to high, and according to the value of m, the prompt lights on the gas dispenser will flash in order of temperature from low to high.

[0068] When there are four filling machines, the LNG submersible pumps corresponding to the filling machines work at the same time. When there are 5 vehicles that need to be filled, the controller obtains the temperature of each pump pool through the station control system, and The temperature of the pump pool is sorted, and the warning light on the gas dispenser corresponding to the pump pool with the lowest temperature is controlled to flash, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com