Three-point type screening method for quick charging/discharging lithium ion battery

A lithium-ion battery and screening method technology, applied in the field of screening based on fast charging/discharging lithium-ion batteries, can solve the problem of battery pack safety, reliability, poor service life, inability to effectively test the performance and status of lithium-ion batteries, etc. problems, to achieve the effect of improving comprehensive capabilities and market competitiveness, improving consistency, and achieving dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

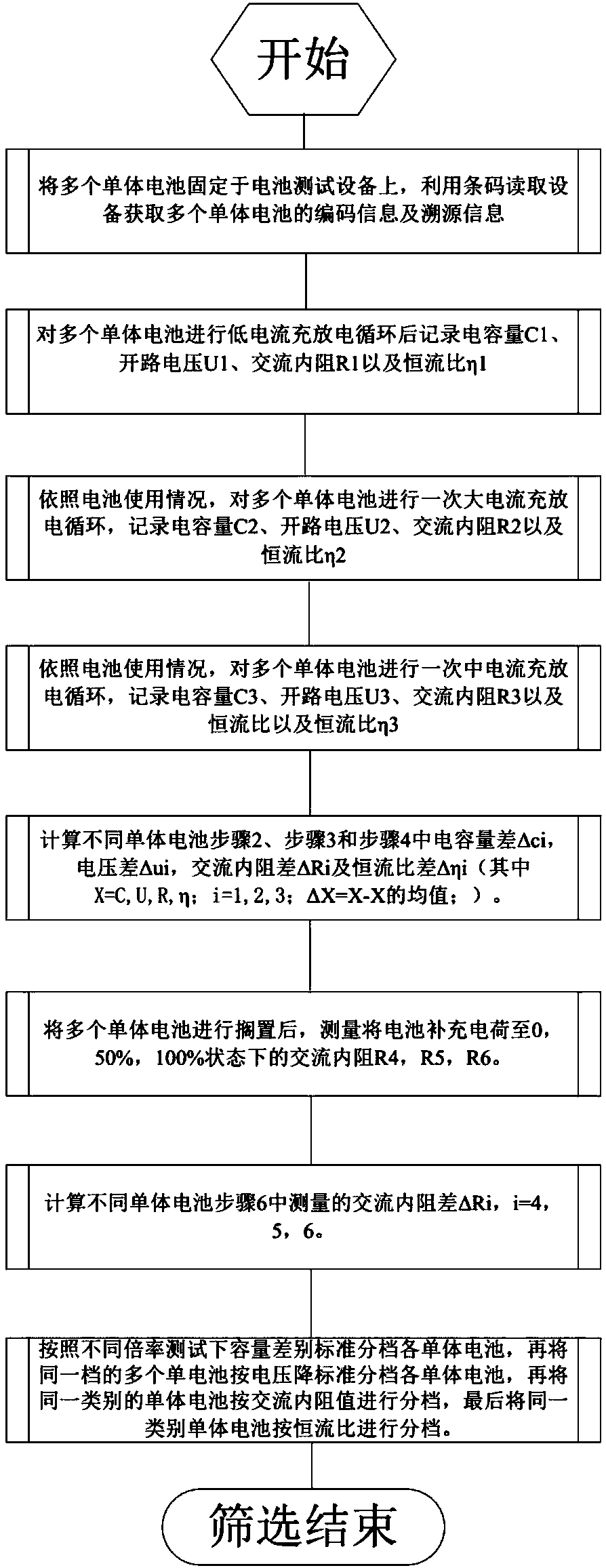

[0029] Such as figure 1 As shown, this embodiment includes the following steps:

[0030] Step 1. Fix the same batch of 18650 lithium iron phosphate batteries with a design capacity of 1500mAH on the battery testing equipment, and use the barcode reading equipment to obtain the coding information and traceability information of multiple single batteries

[0031] Step 2. Record the capacitance C1, open circuit voltage U1, DC internal resistance R1 and constant current ratio η1 after performing a low-rate 0.2C charge-discharge cycle on multiple single cells, specifically including the following steps:

[0032] 1) Charge with a constant current of 0.2C (0.3A) to a rated voltage of 3.7V to obtain a constant current charging capacity C 01 ;

[0033] 2) Under this voltage, charge at a constant voltage to a current of 30mA to obtain battery capacity C1;

[0034] 3) Set aside for 5 minutes;

[0035] 4) Carry out a constant current discharge of 0.3A to a voltage of 2.0V. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com