Laser marking system based on computer control

A laser marking and computer technology, which is applied in the field of laser marking systems, can solve problems such as the lack of ability to process graphics files, achieve the effects of enriching interface control functions, improving control and processing speed, and reducing system wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

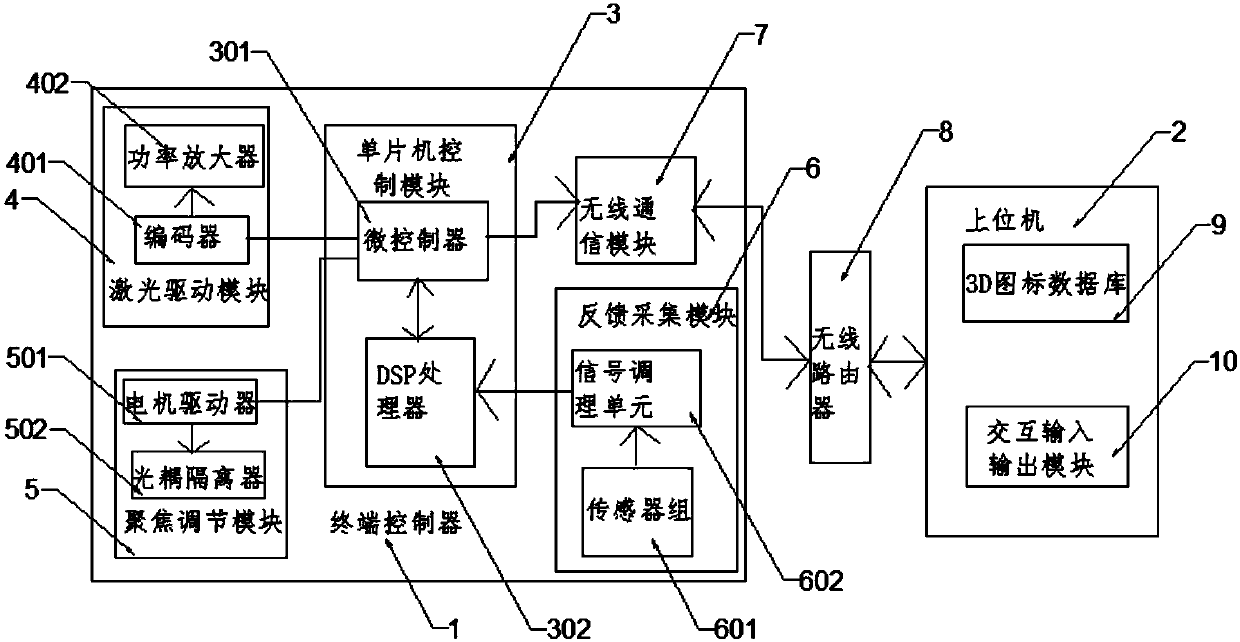

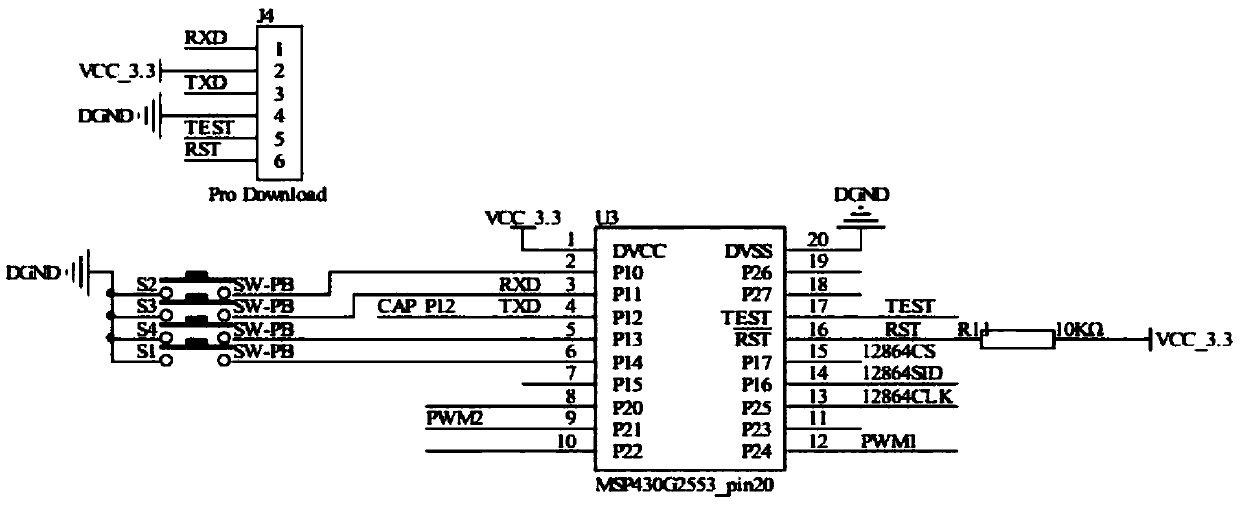

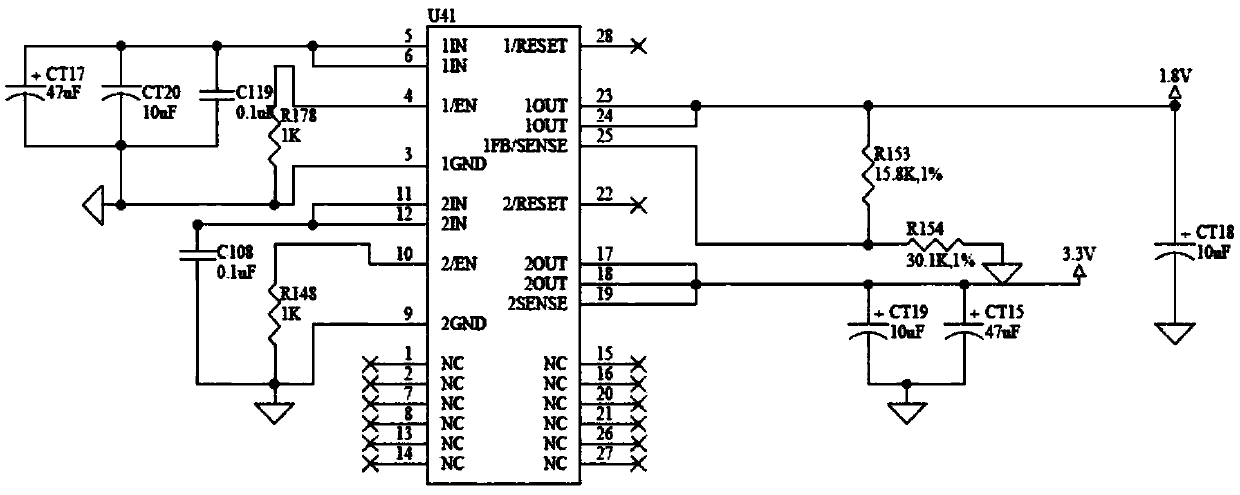

[0029] Such as figure 1 As shown, the present invention provides a computer-controlled laser marking system, including a terminal controller 1 and a host computer 2, the terminal controller 1 is installed on the laser, and the terminal controller 1 and the host computer 2 are connected via wireless channel for data transmission; the terminal controller 1 includes a single-chip control module 3, and the GPI O port of the single-chip control module 3 is connected with a laser driver module 4 and a focus adjustment module 5 through a cable, and the laser driver module 4 is connected to The driving end of laser, focus adjustment module 5 is connected to the adjustment end of focusing system; The SPI port of described single-chip microcomputer control module 3 is connected with feedback acquisition module 6, and described feedback acquisition module 6 is connected to laser and focusing mirror system, single-chip microcomputer control The communication port of module 3 is also conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com