Production apparatus of anethole rectifying section

A technology for production equipment and rectification section, which is applied in the production equipment field of anethole rectification section, can solve the problems of inability to accurately grasp the discharge time, affect anethole discharge, and affect the purity of anethole, so as to prevent air flow back Suction, reduce energy consumption, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

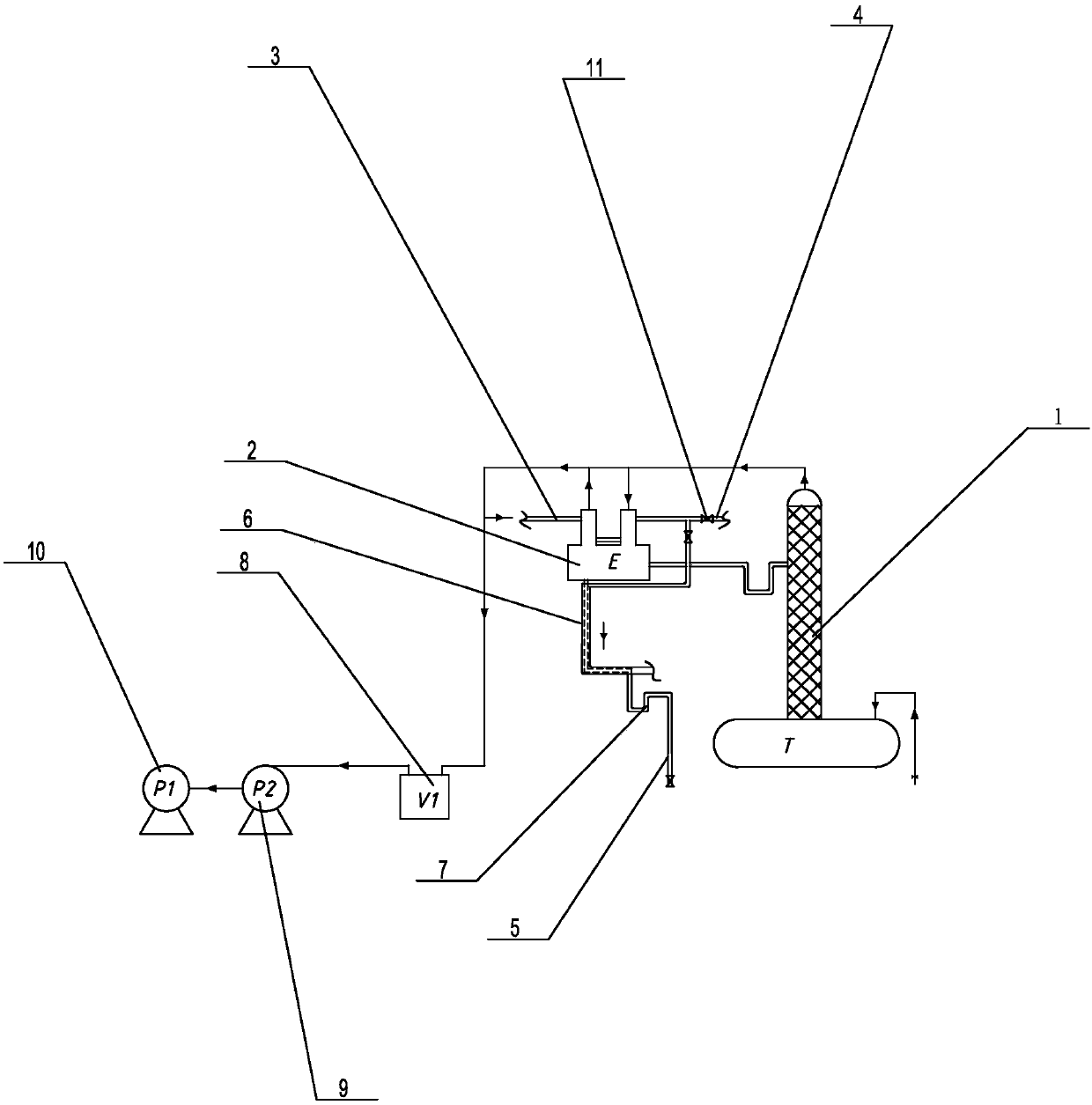

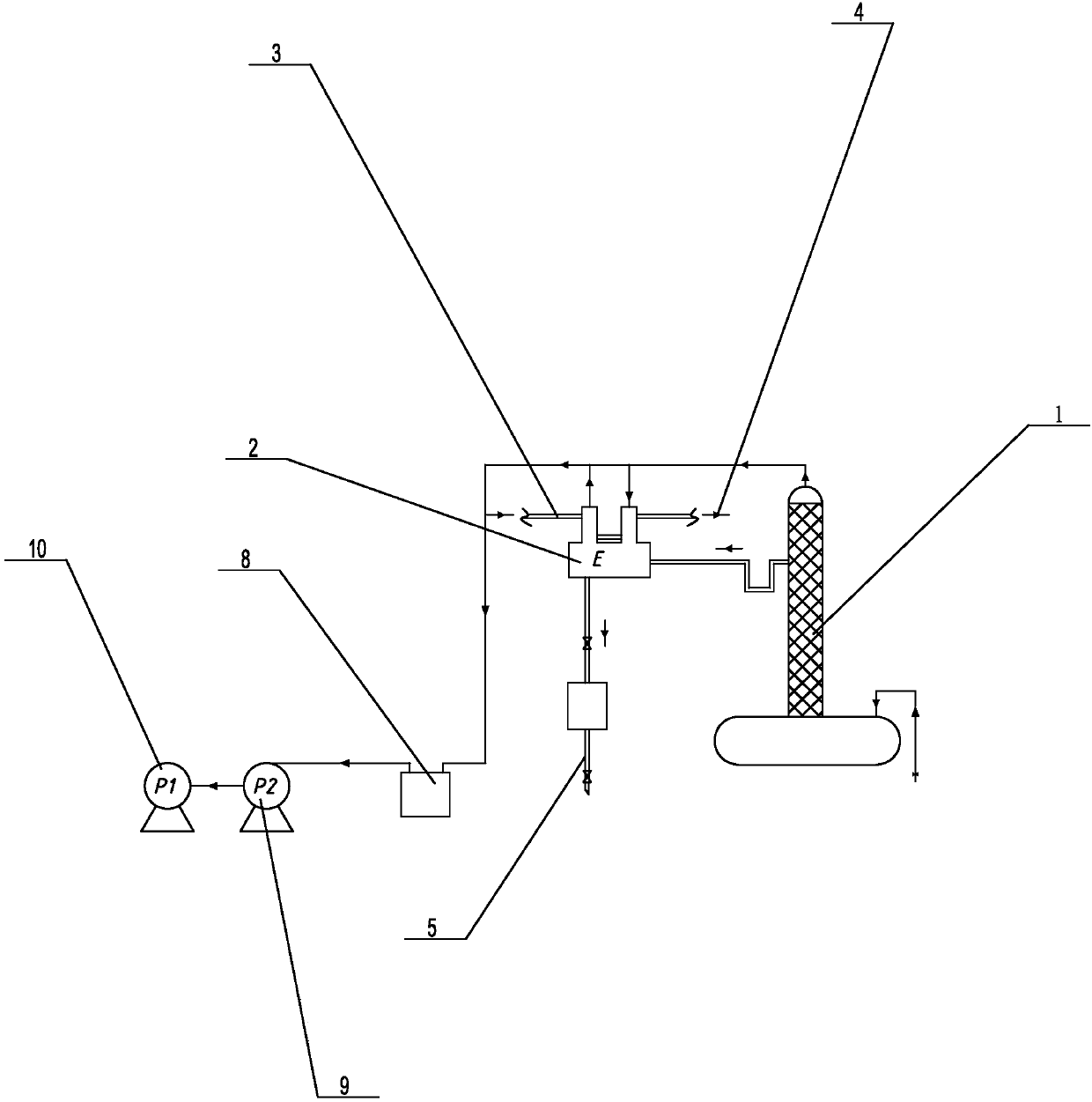

[0017] Such as figure 1 Propose a kind of specific embodiment of the present invention as shown, the production device of anethole rectification section, comprise rectification tower 1, the condenser 2 that is connected with rectification tower 1 successively by pipeline, extract vacuum mechanism, described vacuum mechanism comprises through The pipeline is connected to the vacuum buffer tank 8, Roots pump 9, and water ring pump 10 in sequence with the condenser 2. One side of the condenser 2 is connected to the condensed water inlet pipe 3, and the other side is connected to the condensed water outlet pipe 4. The bottom end of the condenser 2 is connected with a discharge pipe 5, the outer surface of the upper end of the discharge pipe 5 is covered with a condensed water insulation sleeve 6, and the bottom end of the discharge pipe 5 is provided with a discharge valve , the condensed water insulation sleeve 6 is connected to the condensed water outlet pipe 4, and the condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com